ver the years I have worked with various safety, compliance, and certification agencies and NRTLs (Nationally Recognized Testing Laboratories) and similar types of labs. Let's call them businesses who make money from certifying products of various sorts. In the past, before legal, finance and operations ruled the world, some of these agencies were not-for-profit organizations which were funded by insurance companies to enhance safety and minimize losses from coverage of fires and damages caused by unsafe conditions in products. Today many or all the NRTLs are businesses who charge like lawyers in billable hours.

ver the years I have worked with various safety, compliance, and certification agencies and NRTLs (Nationally Recognized Testing Laboratories) and similar types of labs. Let's call them businesses who make money from certifying products of various sorts. In the past, before legal, finance and operations ruled the world, some of these agencies were not-for-profit organizations which were funded by insurance companies to enhance safety and minimize losses from coverage of fires and damages caused by unsafe conditions in products. Today many or all the NRTLs are businesses who charge like lawyers in billable hours.

This approach to safety and compliance certification has changed how test labs conduct business to the point where your success in obtaining certifications for your new product will depend to a large extent on which laboratory you choose to work with. And in my experience, your success will also depend on who you get assigned to at that particular NRTL. Success in this case involves meeting your goals for budget and time to market on your project. This article recounts a series of compliance stories, let's call them case studies, in which companies encountered difficulties in attempting to obtain safety certifications.

As these stories illustrate, there are a variety of pitfalls in the safety approvals process, often relating to the unfortunate choice of an NRTL that places profit over serving the customer. But as we'll also see, choosing the right NRTL and the right lab representative can not only avoid the nuisance problems caused by the laboratory, but also educate the customer on better design choices that will ultimately make compliance easier.

This article focuses on the problems that occur when companies seek safety compliance certifications. But before we delve into examples of these problems, let's consider some of the reasons why the choice of test lab is more of an issue with safety than with other compliance certifications.

How Safety Compliance Differs from Other Areas

First, let's define in today's landscape what compliance regulatory certifications are needed to make a product that can be sold in the marketplace. These include global environmental and materials certifications, radiated and conducted EMI-RFI, CE certification, energy efficiency standards, and electrical safety/flammability of materials. In some cases, all of these must be met. So, let's look at these areas one by one.

Environmental and materials content has turned into a mandatory disclosure area with penalties to the OEM for not conforming. While very onerous and time consuming, this process is pretty black and white. What components comprise your product inside the shipping box? And probably these days you must also disclose the contents of your shipping box, including cords and cables and perhaps even the composition of the box as well. Nevertheless, it's scientifically cut and dried.

With radiated and conducted emissions, you either meet the standard or you don't via methodology and measurements. It's pretty much a pass or fail situation and you want to pass with margin to account for production deviations.

CE is all about whether your product conforms to European health, safety, and environmental protection standards, which mostly encompasses the same items as RoHS and Reach. The CE certification is a super big deal in Europe but not a factor in the U.S. It's mostly obtained by hiring a consultant, paying them, and filling out documents in which you attest that your product adheres to the standards—tick a box and you get CE certification.

Energy efficiency standards, while they vary country by country and range from mandatory to voluntary, are also applied in scientific ways. You measure the energy consumed in various modes of operation and the product either conforms or not. If it doesn't, you re-spin the software or the hardware design until it meets the standards, and then you are certified to the standards. It's measured and validated, and again, data wins. It's a pass-fail situation. In some cases, you are allowed to self-disclose (self-certify the product).

However, what I have observed in the safety area has been very different from these other types of certifications. In my experience, it depends not only on the company you choose to certify your product, but also on who you get to work on your product certification at that agency. Without naming names of organizations, I have seen situations where one NRTL certifies a product or subsystem—and since we are in the power electronics industry lets be specific to merchant power supplies—but another NRTL rejects that certification.

The compliance process has become so challenging that some see this situation as a business opportunity. I was amazed to recently see an advertisement by a group of former NRTL test employees that will, for a fee, coach and guide you on how to get your product prepared for getting through the process at a specific, or perhaps all NRTLs. That's somewhat the reverse of a situation in the healthcare industry where insurance companies are paying retired dentists and doctors to help them reject or delay claims!

In theory, power supply makers usually will only need to get certification from one NRTL and all the other NRTLs are supposed to accept those test results. However, some labs have learned that doing so doesn't maximize billable hours. This statement is not meant to impugn all NRTLs. There are a lot of top-certificating organizations who are moral and ethical. But there are some for whom the guiding principle seems to be just "is it legal, and what can we get away with?" We'll see examples of both in the following stories.

Case 1: When NRTLs Don't Accept Each Other's Work

A large scientific instrument company designed a new instrument using a power supply which was previously certified by NRTL "A". This power supply meets not only the industrial standards that the instrument must conform to, it also meets medical electronic specifications IEC 60601 3rd edition and 4th edition EMC—both of which are more stringent specifications than that required of the industrial instrument. The power supply also meets IEC 62368 and legacy IEC 60950 IT power supply standards.

In this scenario, the instrument maker submitted their new instrument to NRTL "B" to certify its compliance with the applicable safety standards. Test lab B ran its tests and found that the product passed all tests. However, NRTL B questioned everything about the power supply and took exception to its previous certifications. They said they cannot accept the certifications from NRTL A, and the customer must completely re-certify and validate the conformance of the power supply to a standard to which it has already been tested and conformed. This would of course cost the instrument maker a great deal of time and money, while generating goodly income for NRTL B.

For the instrument manufacturer, the options included paying the NRTL to redo the testing, which was unnecessary, switching the project to another NRTL or redesigning the product with a power supply that the NRTL would find acceptable. It's likely that had the instrument company used another NRTL, the power supply would have been accepted and the product would have passed readily. Although, it's also possible that something else might have been brought up instead as an excuse not to pass the product. Frankly, it's also possible that had they been assigned another individual at that same NRTL it would have passed as well. But regardless of the solution, is the product any safer or more compliant because of how NRTL B handled the certification?

In the end, the instrument maker did in fact switch to another NRTL and they passed safety approvals without any issues. Of course, they had to pay the first NRTL for the time and aggravation as well as the NRTL they ended up using.

Case 2: Problems Within a Single NRTL Organization

A medical product company decided to use NRTL "C" to certify their new product for global sales. NRTL C has branches around the world. It's the same organization—just with different branches.

The medical product manufacturer developed its product in North America using a power supply which was designed in Europe. Then it submitted the product to a branch of NRTL C in North America for certification. As is customary during the certification process, the NRTL created a list of "things we need more information about" or that the customer simply must change. In this case, NRTL C took exception to the certifications of the power supply and would not accept them.

However, the medical product company quickly pointed out that those power supply certifications were from the NRTL C organization, so how could they possibly have an issue with them? It would be taking exception to its own work one would think.

The answer was that NRTL C Americas and NRTL C Europe are different entities, and the Americas branch would not automatically honor the certification of their European colleagues. In this case, the customer elected to pay NRTL C Americas to re-certify NRTL C Europe's work. It was paperwork only and no further testing was done. So, is the product safer or more compliant due to this?

Case 3: When It's Easier to Find a New Lab

Another medical instrument company submitted their product to NRTL "D" for approval. Here, the NRTL took exception to the type of plastic used in the product case. Their concern was not related to flammability, but rather the insulation barrier and conductivity of the plastic used in the chassis. Unfortunately, changing the type of plastic, the vacuum molding set-up and die, and associated things to modify this aspect of the design, especially at this late stage, would cost a great deal of money. This change would also add delays to the project launch, resulting in a loss of market share to the medical instrument company.

The solution in this case was to move to another NRTL, which passed the product to the same specifications with no changes made. Had the instrument company submitted their product to a different NRTL in the beginning, or possibly just been assigned to a different individual at NRTL D, they might have passed compliance testing with no problems.

Case 4: When the Lab Doesn't Test Appropriately

In this situation, a third medical instrument company was failing hipot testing with a power supply that had passed medical electronics standards with some margin. The maker of the power supply states they do so right on the product and offers documentation for same. But the NRTL doing the hipot testing was using ac testing and damaging the Y capacitors in the power supply in the process.

The standard allows for dc equivalent testing, and it was pointed out to the NRTL that all they were doing was damaging the Y capacitors and not measuring the actual safety barriers of the power supply. Nevertheless, they continued to test and damage power supplies, charging the customer for their time and of course damaging power supplies so that they could not be used after the destructive testing.

In this case, the power level was low, and the medical instrument company had chosen to embed the offline power supply in their product. However, because of the problem with getting the product to pass hipot, I recommended to the medical instrument company that they re-design the product to get all high voltage out and just have a low-voltage sealed connector on their product. Then they could use an external "wall wart" power supply with as many approvals and medical certifications as I could find at that power level.

The NRTL accepted the external power supply's certifications and stopped hipot testing. For some reason, this external power supply approach with a fully certified one was such that no testing was needed on the power supply and the medical product passed safety certification immediately using the same NRTL from start to finish. Was that necessary? The product in the end might have been safer or not. But the low-voltage approach was a better one as it passed the burden of passing hipot onto the power supply vendor, so I have mixed thoughts on this one.

Case 5: When the Lab Gives Good Advice

A customer decided to design their own power conversion in an industrial product and went to NRTL "E" for testing. The customer had made many mistakes in the design including not using bridge rectifiers which had safety certifications including those for flammability compliance. The NRTL flagged these issues and also objected to the X and Y caps and other items connected to the mains. The laboratory recommended that the customer simply use a commercial power supply that had all the necessary documentation and not try to build their own.

In this case, NRTL E did a good job because it educated the customer that they really should not be designing their own power supplies. Although it was a blow to their egos, they were not better at it than companies which design and build power supplies as their end products. In this case it I wondered if they had gotten another tester at NRTL E or used another test company, would they have passed the product? Would that have been the right thing to do? In the end, it was better that the medical company used a commercial medical power supply—whether they knew it or not.

Case 6: Some NRTL Reps Go Out of Their Way to Help

While working at a power supply company, I had once provided extensive information to NRTL "F" on a certain power supply that was being used by one of our customers in a medical product. That power supply was originally approved by another NRTL, so the agent at NRTL F was just doing the research to confirm the power supply's compliance. That done, the medical product was approved.

Sometime later, I was contacted again by NRTL F about their testing of another medical product from a different company, also our customer. It turned out this second customer was using the same power supply as the previously approved medical product discussed above.

Once informed of the test lab's previous experience with the power supply, the NRTL F representative informed me that he didn't need any more information. He would simply take the data he already had from the past product approval and use it for this second medical device customer.

Now that was class. Since the present medical customer didn't know about the power supply's history, the NRTL representative could have easily charged the customer full price and billed hours for learning about something they already knew and making it new all over again.

NRTL F did the right thing both times. They could have given the first customer a hard time because the power supply was originally approved by another NRTL. But they just confirmed the approval and accepted it. Then they could have charged the second customer for redoing the research, or even rejected the power supply's approval from another NRTL. But they did not do those things.

In both cases, they saved our mutual customers time and money. I hope the individual didn't get in trouble for being helpful, efficient, and using common sense. These days in most organizations, "following the process" is more important than results.

Case 7: Promises Made But Not Delivered

A scientific instrument company submitted a project to NRTL "G" who promised the customer a timeline for completion of the project to certify their product. The project was assigned to an individual at the lab who started to work on the project and sent the customer lots of questions to answer. The customer answered the questions and NRTL G went dark on asking for anything else.

So, it was assumed that the project was being worked on. It turned out that the employee at NRTL G left and the project was not reassigned. But this was just the beginning of the problems. It seems that NRTL G had a systematic problem with turnover, so the project would be handed off to a new representative several times. And every time a new person was placed on the project, a different set of questions was asked, and there was no mention of the questions asked by the prior employee. The project was new repeatedly.

This of course cost the company time and money and the solution in the end was that the scientific instrument company changed NRTLs. With compliance being handled by a different lab, the customer was served with a small list of questions, which they answered, and the product passed without further incident.

How to Avoid Safety Compliance Nightmares

What can we learn from all this? The system works sometimes and sometimes not. In some cases, the exceptions taken seem to be more about maximizing billable hours than about verifying safety and compliance. Sometimes this system gives you a better product, but often the equipment maker doesn't change anything on the product—lots of paper (or now electronic files) just get moved around and money changes hands.

So how can you avoid having to pay out a lot of money or wasting a lot of time? If your organization has an internal safety and compliance group and/or you can self-certify, that is often the best situation. Your internal team can collaborate with you early to avoid potential certification issues.

If you must go outside for compliance testing, keep in mind that the mindset of your NRTL partner might not be to help you achieve your goals in a timely manner. Don't believe for a second that all NRTLs are the same, they are not. You should interview them ahead of time, interview who they are going to have working on your project and give a "not to exceed" quotation for the project.

If they say they can't quote it until they have more information, then let them know you will supply the information needed to quote. Otherwise, you are giving them a blank check to have their way with you. If no exceptions are taken during the quoting process, why would they become an issue after the project starts? Well, that's because you were a prospect before and now you are a client customer—if the rules change after the fact, you are too far in.

Also ask for the background on the person doing the work for you. How many years do they have working on projects such as yours? How long have they been with the NRTL? If they will let you involve them early and often in the product development process, it may prevent problems later, as it becomes more expensive to change things as the project moves along the development pipeline.

You may think that since the person works at a big NRTL organization they must be competent, right? Well don't assume that. Ask to interview the person who is going to be doing the work and ask about qualifications, longevity, projects worked on successfully, etc. Interview them like you are interviewing a prospective employee. If you don't like the answers, request another person or find another NRTL.

Another tip is to choose sub-assemblies with compliance in mind. Do the equipment and components being selected meet all the usual necessary and customary compliance certifications with documentation available to back up claims?

Finally, talk to other customers of the NRTL being considered, ask for references, and call them—what has been their experience working with the lab? Do they stick to the set price or are they constantly finding reasons for billing more hours? Don't forget that selecting an NRTL and staff to work with is like interviewing a potential employee. You will potentially live with this decision for a long time, and they can cause delays and costs to spiral out of control such that the only way to fix it will be the application of more time and money.

Choose carefully and involve the lab early, keeping in mind that you are more likely to have a good result if you set clear expectations on both sides from the start. If you think that the nightmares described in this article cannot happen to you, consider that neither did any of the companies involved in these stories. By the time, these companies discovered their problems, they were too far into the compliance process to fix them easily and resolving them required much more time and money than they had expected to invest.

Author: Kevin Parmenter

Director of Applications Engineering

Taiwan Semiconductor America |

|

Editor's Note: This article was first published in the October 2021 issue of How2Power Today (http://www.how2power.com/newsletters/index.php).

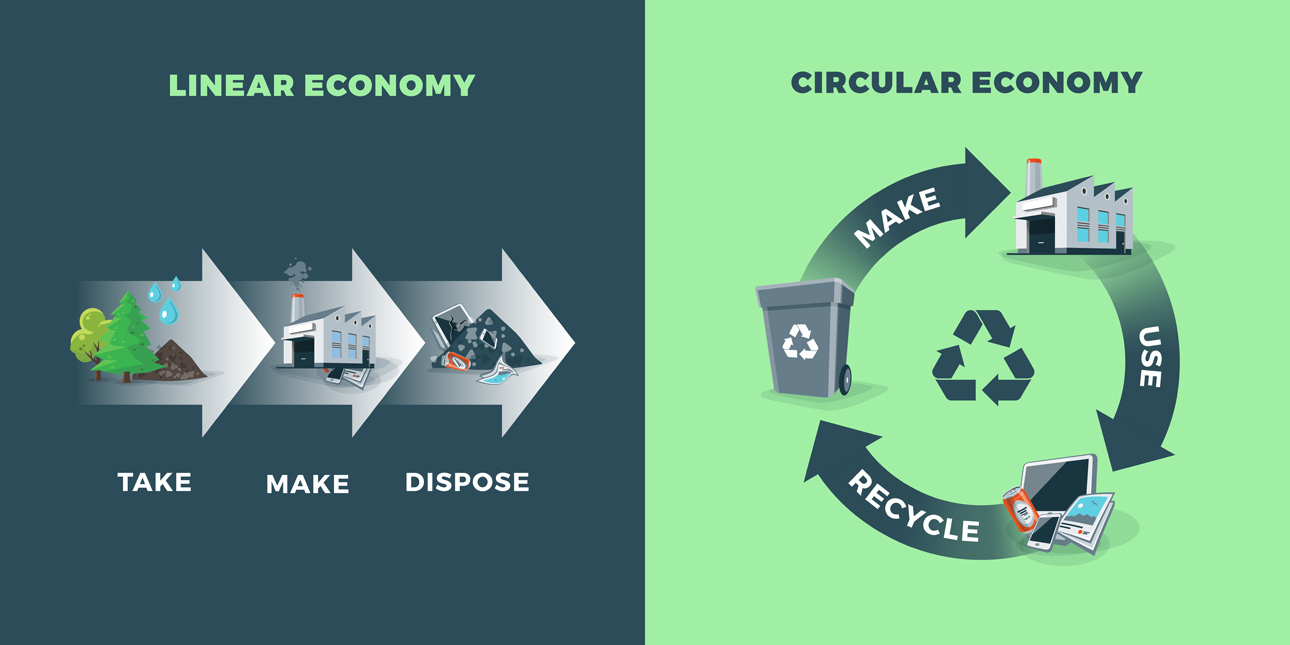

Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock)

Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock) Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock)

Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock) Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock)

Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock) Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX)

Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX)

ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference (

ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference ( 22, started bright and early with the WiE Roundtable Breakfast held n the main hallway of the Huntington Place Convention Center. Unlike the free-for-all format of the previous evening's social event, this event was more structured with many tables each representing a different area of focus that were led by table leaders and mentors from the respective area. PSMA was represented by Greg Evans & Stephanie Watts-Butler supported the event. Several attendees coming to the PSMA table were not previously familiar with the organization and expressed gratitude for having this industry-focused component as part of the overall ECCE program to enhance their industry involvement, and hopefully help to accelerate their own careers. The participants also seemed interested to learn more about getting involved in PSMA activities and programs and were interested in learning more about APEC and other PSMA-sponsored/organized events.

22, started bright and early with the WiE Roundtable Breakfast held n the main hallway of the Huntington Place Convention Center. Unlike the free-for-all format of the previous evening's social event, this event was more structured with many tables each representing a different area of focus that were led by table leaders and mentors from the respective area. PSMA was represented by Greg Evans & Stephanie Watts-Butler supported the event. Several attendees coming to the PSMA table were not previously familiar with the organization and expressed gratitude for having this industry-focused component as part of the overall ECCE program to enhance their industry involvement, and hopefully help to accelerate their own careers. The participants also seemed interested to learn more about getting involved in PSMA activities and programs and were interested in learning more about APEC and other PSMA-sponsored/organized events.

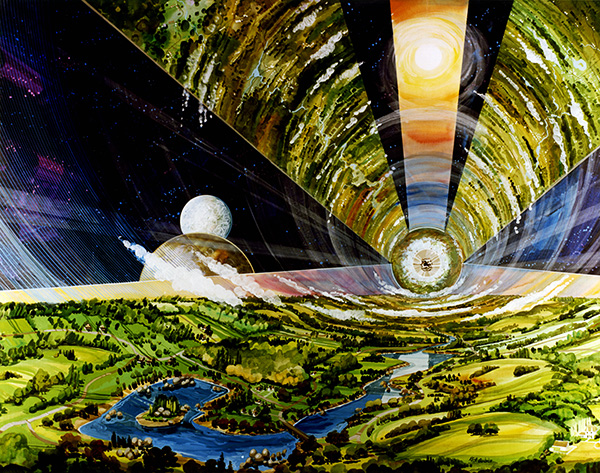

Figure 01 - O’Neill Cylinder interior - Painting by Rick Guidice (Source: PRBX/NASA)

Figure 01 - O’Neill Cylinder interior - Painting by Rick Guidice (Source: PRBX/NASA) Figure 02 - Solid State Lighting to grow vegetables in indoor farming (source PRBX / asharkyu-Shutterstock)

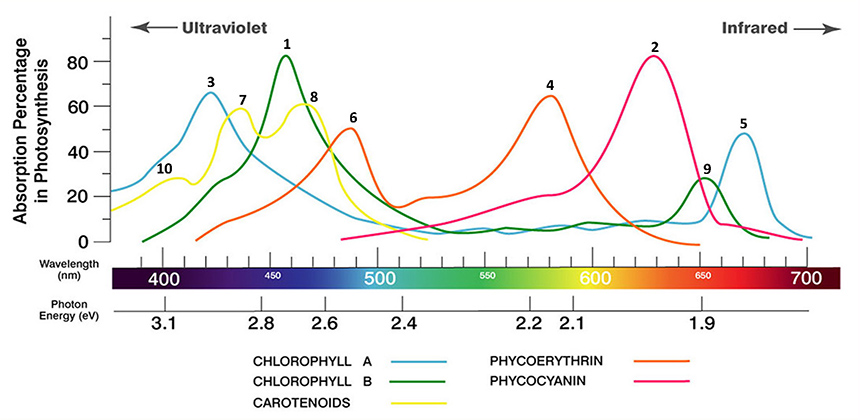

Figure 02 - Solid State Lighting to grow vegetables in indoor farming (source PRBX / asharkyu-Shutterstock) Figure 03 - The light spectrum to grow plants and vegetables typically starts at 450 nm (blue light) and goes through 730 nm (far red) (source PRBX)

Figure 03 - The light spectrum to grow plants and vegetables typically starts at 450 nm (blue light) and goes through 730 nm (far red) (source PRBX)

Figure 05 – COSEL power supply with multi-modes for voltage or current constant from max to near zero (Source PRBX/COSEL)

Figure 05 – COSEL power supply with multi-modes for voltage or current constant from max to near zero (Source PRBX/COSEL) Figure 06 - NASA astronaut Peggy Whitson looks at the Advanced Astroculture Soybean plant growth experiment (Source: PRBX/NASA)(Source PRBX/NASA)

Figure 06 - NASA astronaut Peggy Whitson looks at the Advanced Astroculture Soybean plant growth experiment (Source: PRBX/NASA)(Source PRBX/NASA) Figure 08 – Efficient Power Conversion (EPC) ruggedized GaN FET for space applications and DC/DC converter (Source: PRBX/EPC)

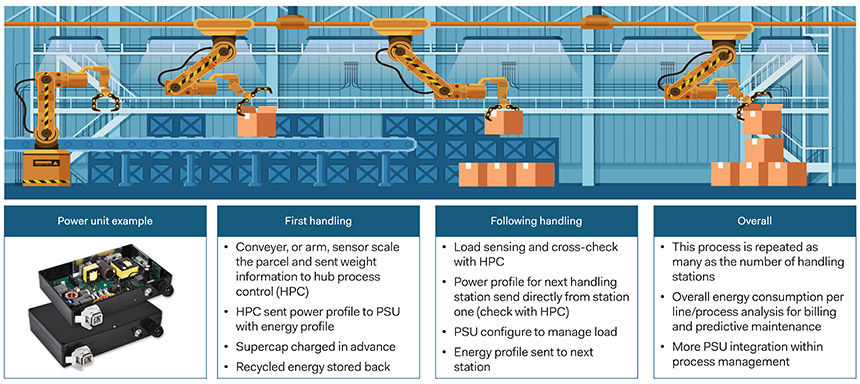

Figure 08 – Efficient Power Conversion (EPC) ruggedized GaN FET for space applications and DC/DC converter (Source: PRBX/EPC) Figure 01: Smart Power operation in Smart Factory with machine-to-machine communication (Source: PRBX)

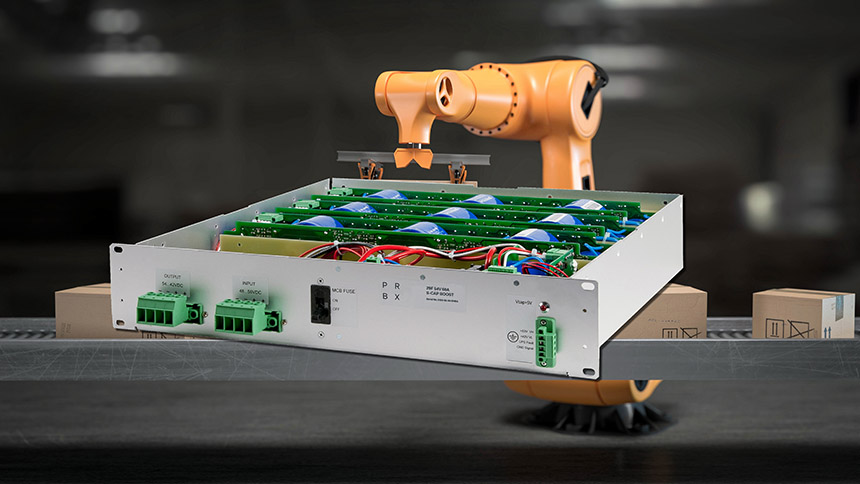

Figure 01: Smart Power operation in Smart Factory with machine-to-machine communication (Source: PRBX) Figure 02 - PRBX S-CAP BOOST supercapacitors bank with digital control and communication interface able to deliver peak energy to load and to store backward energy (Source: PRBX)

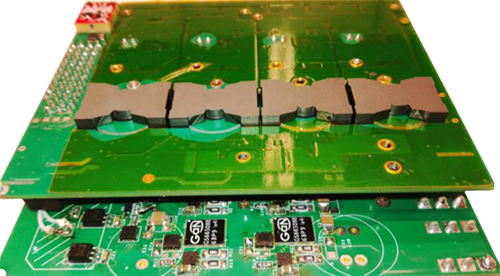

Figure 02 - PRBX S-CAP BOOST supercapacitors bank with digital control and communication interface able to deliver peak energy to load and to store backward energy (Source: PRBX) Figure 03 - PRBX multi-cores auto-tuned power converters with advanced digital control and GaN FET transistors (Source PRBX)

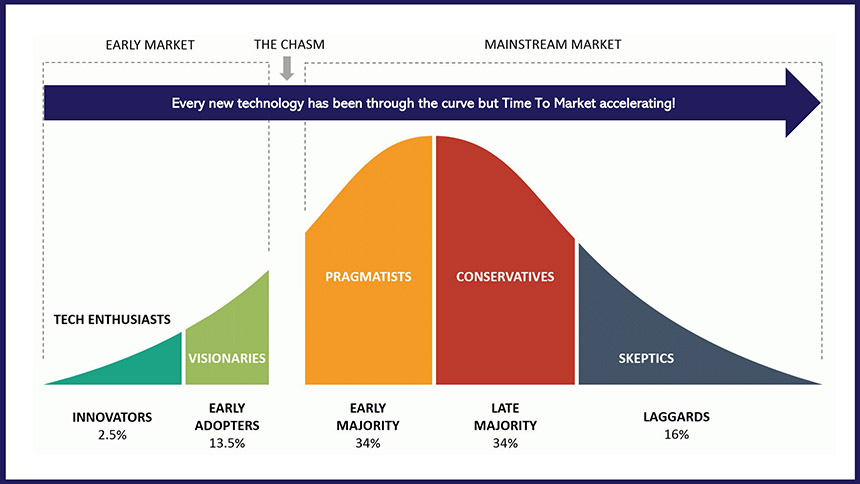

Figure 03 - PRBX multi-cores auto-tuned power converters with advanced digital control and GaN FET transistors (Source PRBX) Figure 04 - Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital (Source: PRBX)

Figure 04 - Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital (Source: PRBX) Figure 05 - Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger, contributing to reduce its size by 26% (Source PRBX/Navitas)

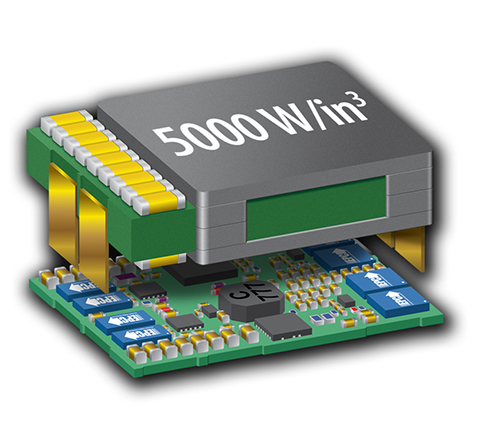

Figure 05 - Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger, contributing to reduce its size by 26% (Source PRBX/Navitas) Figure 06 - Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Source: PRBX/EPC)

Figure 06 - Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Source: PRBX/EPC)

Powerbox, one of Europe’s largest power supply companies, and for more than four decades a leading force in optimizing power solutions for demanding applications, announces it has consolidated its Swedish operations to a new facility located at Hägersten, South of Stockholm.

Powerbox, one of Europe’s largest power supply companies, and for more than four decades a leading force in optimizing power solutions for demanding applications, announces it has consolidated its Swedish operations to a new facility located at Hägersten, South of Stockholm.

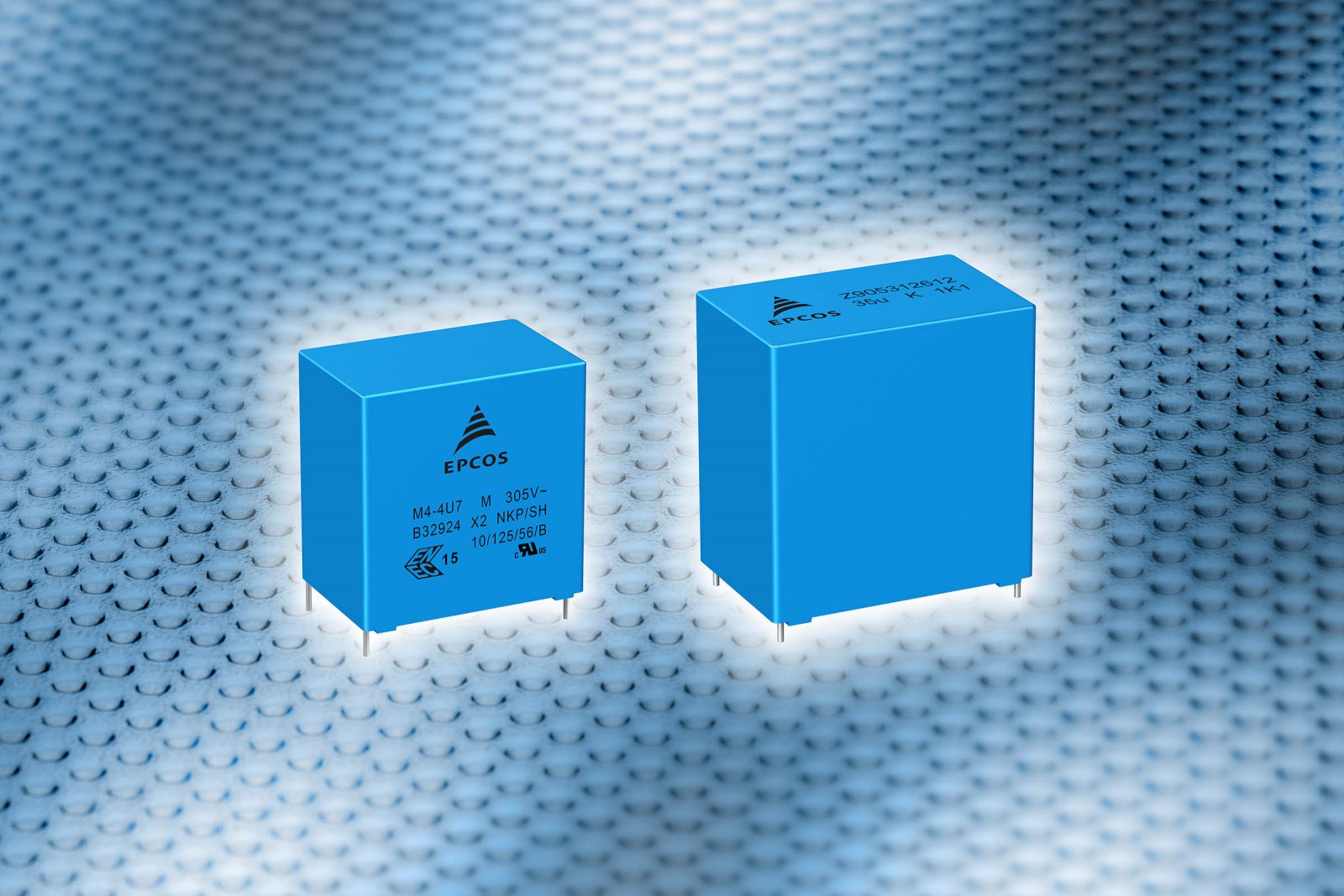

TDK Corporation presents the new, powerful and intuitive CLARA tool (Capacitor Life And Rating Application) for calculating and selecting EPCOS and TDK film capacitors for PCB mounting. The tool offers a versatile parametric search functionality. This includes a search for capacitance, voltage range as well as for rated voltage, RMS and peak current, temperature, maximum dimensions and volume, approvals, reference standards as well as typical applications.

TDK Corporation presents the new, powerful and intuitive CLARA tool (Capacitor Life And Rating Application) for calculating and selecting EPCOS and TDK film capacitors for PCB mounting. The tool offers a versatile parametric search functionality. This includes a search for capacitance, voltage range as well as for rated voltage, RMS and peak current, temperature, maximum dimensions and volume, approvals, reference standards as well as typical applications.

l

l

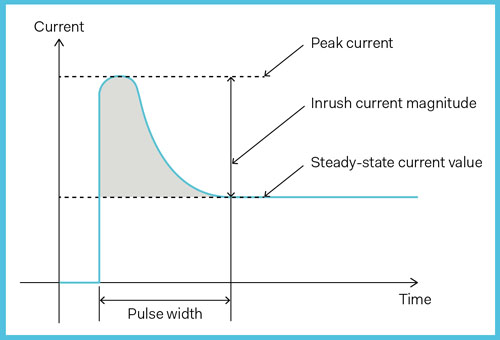

.jpg) TDK Corporation presents a new, user-friendly tool to help users select the right PTC inrush current limiters (ICL) for a range of different power supply and converter topologies. The intuitive tool is available online and does not need to be downloaded. The selection process is divided into four stages: After specifying the circuit structure and the capacitor bank's total capacitance, the developer must then enter the charging voltage and the maximum ambient temperature of the PTC inrush current limiter. After this has been done, the tool displays a list of suitable components for the user, and if a parallel connection is required, the number of components required is also shown. The most important key figures are also shown, as well as links to service distributors that sell the PTC ICLs.

TDK Corporation presents a new, user-friendly tool to help users select the right PTC inrush current limiters (ICL) for a range of different power supply and converter topologies. The intuitive tool is available online and does not need to be downloaded. The selection process is divided into four stages: After specifying the circuit structure and the capacitor bank's total capacitance, the developer must then enter the charging voltage and the maximum ambient temperature of the PTC inrush current limiter. After this has been done, the tool displays a list of suitable components for the user, and if a parallel connection is required, the number of components required is also shown. The most important key figures are also shown, as well as links to service distributors that sell the PTC ICLs.

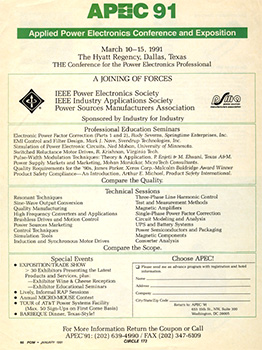

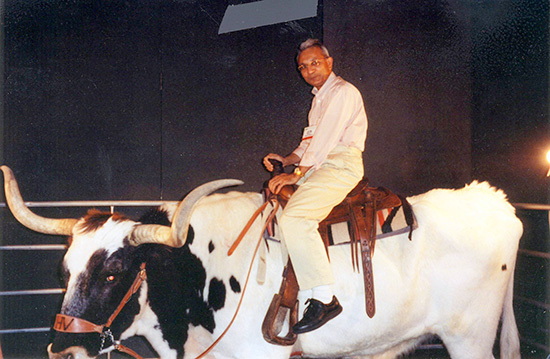

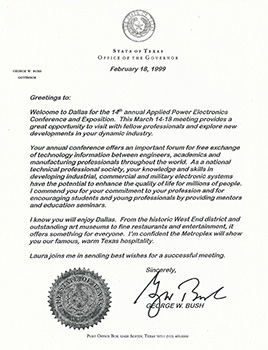

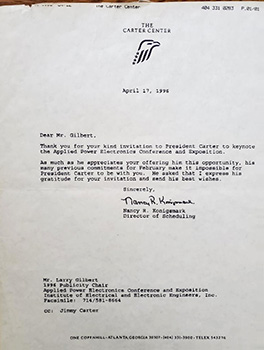

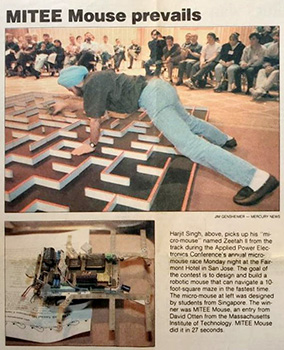

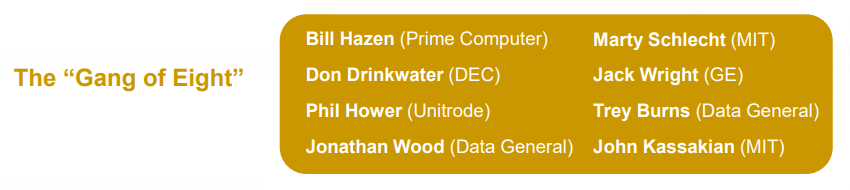

First APEC Social (All 250 Attendees)

First APEC Social (All 250 Attendees)