|

ULS was founded 40 years ago in Munich, Germany with a handful of engineers and one common goal; to revolutionize power supply technology. Today, PULS is the leading manufacturer of the most efficient DIN-Rail switched mode power supplies and DC power products. This was made possible by our focus and a global team that strives for the next stage of innovation for every PULS product. Users can experience this ambition in the highest efficiency levels, longest service lifetimes, smallest form factors, and absolute reliability of all PULS products.

PULS is committed to developing and producing leading edge technologies and energy efficiency is at the heart of all PULS product designs. Achieving the highest efficiency ratings possible reduces exess heat generation, minimizes power losses, and extends the service lifetimes of PULS products to provide users with the lowest total cost of ownership. Minimizing excess heat generation also extends the lifetimes of surrounding components located near PULS power supplies. The wide breadth of the PULS product offering enables users to select the best PULS products for their individual application requirements. PULS products are frequently used in Proccess Automation, Material Handling, Food & Beverage, Semi-Conductor, Railway, Renewable Energy, Water & Waste Water, Automotive, and Building Automation applications throughout the world. PULS is committed to developing and producing leading edge technologies and energy efficiency is at the heart of all PULS product designs. Achieving the highest efficiency ratings possible reduces exess heat generation, minimizes power losses, and extends the service lifetimes of PULS products to provide users with the lowest total cost of ownership. Minimizing excess heat generation also extends the lifetimes of surrounding components located near PULS power supplies. The wide breadth of the PULS product offering enables users to select the best PULS products for their individual application requirements. PULS products are frequently used in Proccess Automation, Material Handling, Food & Beverage, Semi-Conductor, Railway, Renewable Energy, Water & Waste Water, Automotive, and Building Automation applications throughout the world.

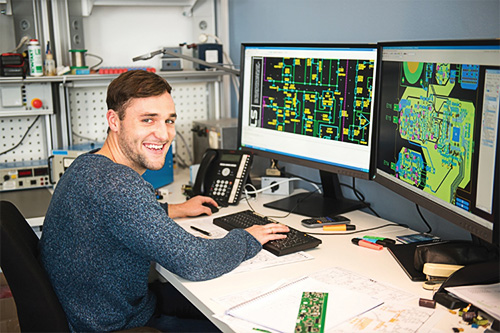

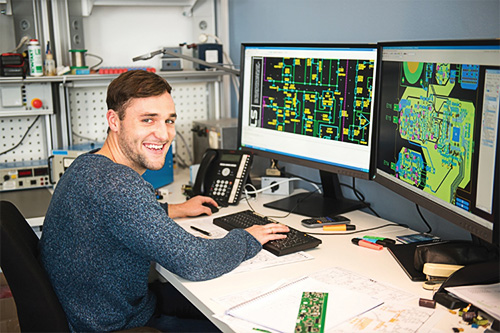

Production of all PULS products is carried out in two innovative and highly automated manufacturing plants in the Czech Republic and China. The entire value chain is kept under our full control, and this level of control is important to us. In customer audits, our plants are repeatedly praised for their efficiency, streamlined structure and environmentally friendly objectives. Owning and operating multiple manufacturing facilities provides PULS the flexibility to ensure seamless delivery for a global market.

Innovative and efficient product designs are just a part of the PULS advantage. PULS provides technical and commercal support globally to support customers needs and requirements. PULS locations throughout the world maintain significant levels of inventory to ensure immediate availability and timely delivery for our customers. Training session are provided regularly to better educate the market on the many critical aspects of PULS' industry leading products. Detailed product specifications, application notes, drawings, agency approvals, and other valuable information can be found at www.pulspower.us

Provided by Matt Biskner,

President & General Manager, PULS, LP

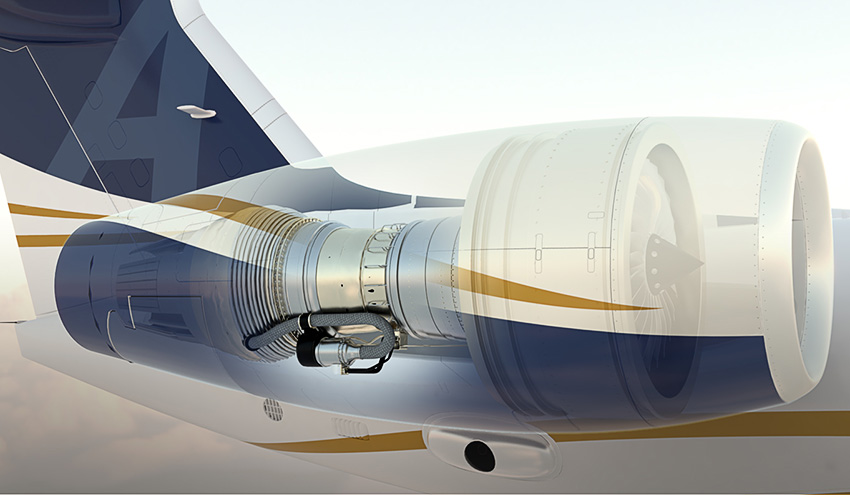

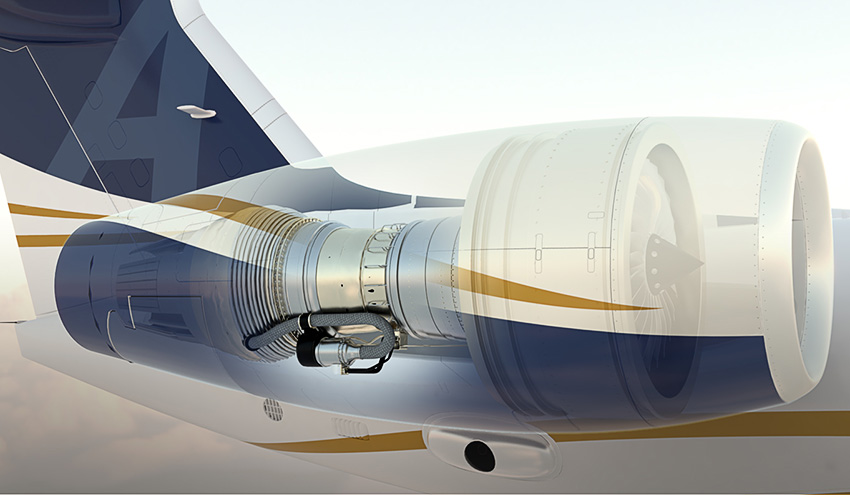

The next time you fly, recognize that it is -40 degrees outside, you are traveling at 500 miles per hour, 6 miles high, and there is not enough oxygen to survive. There are several hundred systems keeping you alive, comfortable, entertained, and flying in this environment. Astronics is the expert providing the power to those systems. |

stronics - Advanced Electronic Systems (AES) serves global customers as the aircraft industry's electrical power experts, offering a breadth of power solutions for commercial transport, business, VIP, rotorcraft, and military aircraft. The company offers airframe power systems as well as the in-seat power systems and outlets that keep passenger devices charged throughout a flight. Astronics AES customers include more than 280 airlines, all major aircraft manufacturers, plus a myriad of military manned and unmanned aircraft manufacturers and inflight entertainment providers. In short, Astronics provides the power systems that support the entire industry. stronics - Advanced Electronic Systems (AES) serves global customers as the aircraft industry's electrical power experts, offering a breadth of power solutions for commercial transport, business, VIP, rotorcraft, and military aircraft. The company offers airframe power systems as well as the in-seat power systems and outlets that keep passenger devices charged throughout a flight. Astronics AES customers include more than 280 airlines, all major aircraft manufacturers, plus a myriad of military manned and unmanned aircraft manufacturers and inflight entertainment providers. In short, Astronics provides the power systems that support the entire industry.

"At Astronics, innovation is in our core," explained Mark Peabody, President of Astronics AES. "We pioneered the in-seat power that passengers use while seated on a plane, and today there are more than a million seats outfitted with our product. Every day, our team members work side-by-side with customers to create exciting new technologies that, like in-seat power, will help transform the future of the flight experience."

To date, Astronics power engineers have generated dozens of patents for power systems on aircraft.

Astronics EMPOWER® in-seat power systems keep

passengers powered throughout a flight.

|

|

Astronics now offers wireless charging for embedding in

furniture and seat backs to charge the newest phones. |

Driving Innovation in Aircraft Passenger and Crew Power Systems

Since launching in-seat power, Astronics has continued to innovate and expand its product line over the years. Today, major OEMS and airlines count on Astronics to provide the industry's most comprehensive, most certified, most widely deployed set of in-seat power solutions in the world.

"Recently we introduced USB Type-C outlets to serve laptops, phones, and other emerging devices powered by this new standard," Peabody said. "And what we're really excited about right now is wireless charging, where we're now able to provide inductive charging for the newest passenger devices. Creating this for the aircraft was a challenge where we had to satisfy stringent power and safety requirements, and today we're thrilled to say many first and business class seat manufacturers are implementing this new technology to service their most tech-savvy passengers."

Astronics in-seat power systems offer real-world impact on passengers and flight crews, enabling them to enjoy inflight entertainment and stay connected to loved ones throughout their journey without worrying about conserving device batteries.

Astronics is helping to drive the development of tomorrow's more electric aircraft. |

On a Mission: To Drive the More Electric Aircraft

Astronics is also deeply involved with the industry drive to the more electric aircraft. From R&D efforts to thought leadership on emerging standards and solving technical issues, Astronics is creating products and systems for tomorrow's innovative aircraft. Astronics is supporting its longtime customers in new initiatives to bring more electrical systems to fixed-wing aircraft, rotorcraft, and now, the emerging class of electrical vertical take-off and landing (eVTOL) aircraft.

"We're thinking about the performance improvements that can be expected in transitioning to an aircraft where more systems are powered and monitored electronically. With our power systems, we're also incorporating smart sensing elements to help with vehicle health management and predictive maintenance. We're pushing power to do more than simply provide power -- we're excited to be introducing a whole new class of intelligent power systems for the evolved aircraft of tomorrow," Peabody said.

For airframe power, Astronics manufactures power generation, power conversion, and power distribution products. Incorporating the latest solid-state technologies and designs, these systems deliver highly efficient, clean electrical power that improves aircraft operation through weight and system wiring savings.

Astronics' starter generator units form the foundation of a more electric airframe power system. |

The Importance of Culture at Astronics AES

Astronics AES considers culture to be at the heart of everything they do – from how they work together to how they serve their customers and their community. The culture tenets include learning, teamwork, humility, life, and at the center of it all, passion. "We believe it is the journey that is impactful – it provides us with opportunities to ask questions, learn from our challenges, and positively affect the lives of many people," Peabody explained.

Astronics employees show their Seattle Seahawks team spirit. |

Located in beautiful Kirkland, WA, Astronics AES draws inspiration from a tech-focused community rooted in aerospace but that now incorporates the fast-forward pace of companies including Amazon, Google, and Apple who also call the Seattle area home.

Astronics AES is a wholly owned subsidiary of Astronics Corporation, which serves the world's aerospace, defense, and other mission-critical industries with proven, innovative technology solutions. Astronics experts work side-by-side with customers, integrating an array of power, connectivity, lighting, structures, interiors, and test technologies to solve complex challenges. For over 50 years, Astronics has delivered creative, customer-centric solutions with exceptional responsiveness. Today, global airframe manufacturers, airlines, military branches, completion centers, and Fortune 500 companies rely on the collaborative spirt and innovation of Astronics. Learn more at Astronics.com.

Provided by Ellen Cheng, Marketing Communication Coordinator, Astronics

Editors Note: We would like to feature your company in a future issue of the Update. Please contact the Association Office for information about how to submit an article for consideration.

|

PULS is committed to developing and producing leading edge technologies and energy efficiency is at the heart of all PULS product designs. Achieving the highest efficiency ratings possible reduces exess heat generation, minimizes power losses, and extends the service lifetimes of PULS products to provide users with the lowest total cost of ownership. Minimizing excess heat generation also extends the lifetimes of surrounding components located near PULS power supplies. The wide breadth of the PULS product offering enables users to select the best PULS products for their individual application requirements. PULS products are frequently used in Proccess Automation, Material Handling, Food & Beverage, Semi-Conductor, Railway, Renewable Energy, Water & Waste Water, Automotive, and Building Automation applications throughout the world.

PULS is committed to developing and producing leading edge technologies and energy efficiency is at the heart of all PULS product designs. Achieving the highest efficiency ratings possible reduces exess heat generation, minimizes power losses, and extends the service lifetimes of PULS products to provide users with the lowest total cost of ownership. Minimizing excess heat generation also extends the lifetimes of surrounding components located near PULS power supplies. The wide breadth of the PULS product offering enables users to select the best PULS products for their individual application requirements. PULS products are frequently used in Proccess Automation, Material Handling, Food & Beverage, Semi-Conductor, Railway, Renewable Energy, Water & Waste Water, Automotive, and Building Automation applications throughout the world.

ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference (

ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference (