Twenty years ago, the adoption of the Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1) was one of the driving forces mandating the electronics industry to look for alternatives to replace the tin-lead eutectic alloy which had been used for decades for soldering purposes. Since then many regulations have sprung up restricting the use of hazardous substances, and we are familiar with RoHS, REACH, TSCA and others. In addition, growing concerns about long term sustainability and optimization of natural resources have motivated governments, institutions and industry to consider how to develop a circular business model, including elements from the cradle-to-cradle concept, and to define an optimum way to trace a product from its origin, its content, its compliance to environmental regulations, its reparability or final disposal and recycling. This materialized in March 2022 by the European Commission as part of the EU Green Deal, and was followed by similar initiatives in the US. But what is it about?!

Here comes the Digital Product Passport

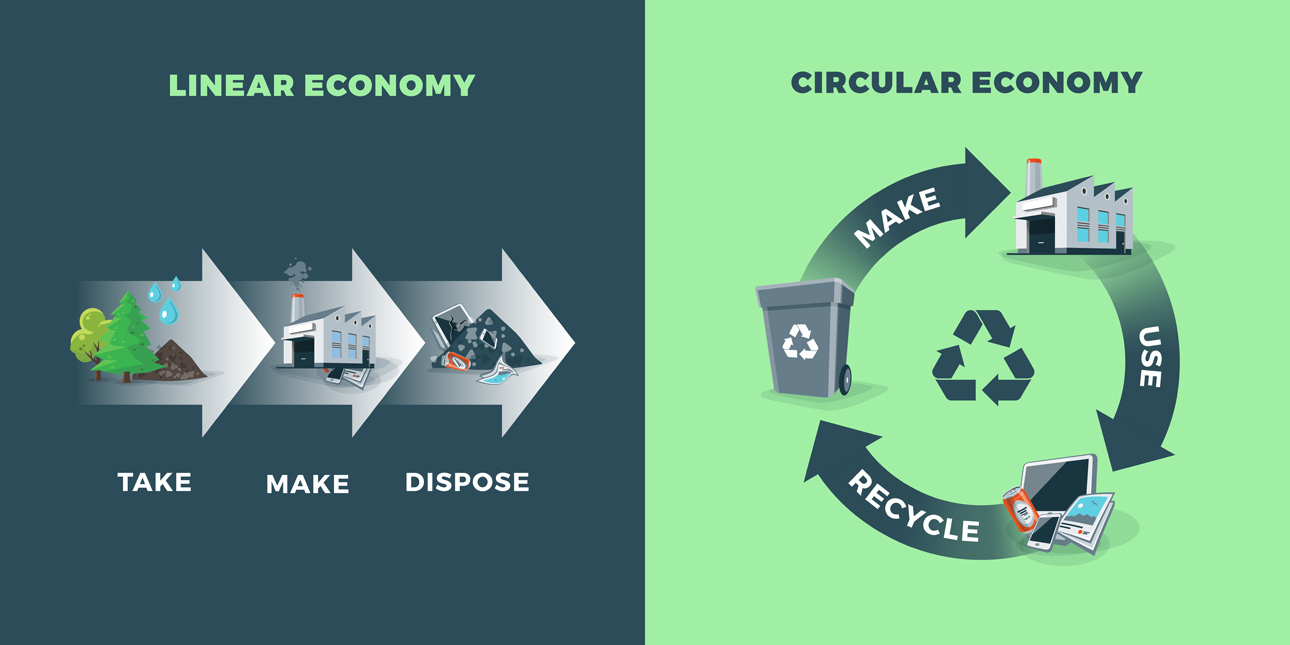

After 10 years of local initiatives, the European Commission presented a package of proposals as part of the European Green Deal to make sustainable products the norm in the EU, moving away from the conventional linear economy by boosting circular business models and empowering consumers for the green transition (Figure 01), including the so called Digital Product Passport (DPP).

Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock) Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock) |

At this point you may question what this has to do with power electronics and how the power supply community may be affected by this new requirement? Where is the threshold between a Point-of-Load, a multi kilowatts power supply or even an Electrical Vehicle? Which power electronics segment will have to comply with the DPP? Read on to better understand and debug what is DPP.

Having the whole life cycle in mind!

The proposal for a Regulation on Ecodesign for Sustainable Products addresses product design, which determines up to 80% of a product's lifecycle environmental impact. It sets new requirements to make products more durable, reliable, reusable, upgradable, reparable, easier to maintain, refurbish and recycle, and energy and resource efficient. In addition, product-specific information requirements will ensure that consumers are knowledgeable on the environmental impact of their purchases.

All regulated products will have Digital Product Passports making it easier to repair or recycle them and to facilitate the tracking of substances of concern along the supply chain. The aim of the passport is to provide producers and other key supply chain actors, as well as consumers and market surveillance authorities, with relevant information for ensuring the sustainable management of products. If well designed, and if aligned with existing industry initiatives, these Digital Product Passports could help to promote the circular economy and circular business models. This may sound quite hypothetical and even complex but let's consider a practical example with the booming energy storage segment and batteries.

The battery industry showing the way!

Since 2006 batteries and waste batteries have been regulated within the EU under the Batteries Directive (2006/66/EC). Though driven by electric transport and energy storage the demand for batteries has increased rapidly and is set to increase 14 fold by 2030. Such global exponential growth in the demand for batteries will lead to an equivalent increase in demand for raw materials, hence the need to minimize their environmental impact.

With high levels of concern for the long term sustainability of the battery industry, in 2017 two major initiatives took place in Europe and the USA. Both of these were similarly aimed: to develop an innovative, competitive and sustainable battery value chain in Europe and the USA with high regards for the environment and society.

In Europe on October 11, 2017, the European Commission hosted auto, chemical and engineering executives in Brussels to strengthen battery manufacturing in the EU and to develop a European ecosystem to reduce dependency and risk in the supply chain of what will become the heart of energy transition and mass electrification. This was followed by the launch of the European Battery Alliance (EBA) as part of Europe's clean and digital transition and a key enabling technology, essential to the automotive sector's competitiveness.

In the USA, in the same year, a public-private collaboration platform was founded at the World Economic Forum to help establish a sustainable battery value chain by 2030, The Global Battery Alliance (GBA).

It can be said that 2017 has been the EU/USA cornerstone for the battery industry setting the basic principles of what will become the DPP and a completely new way of working, integrating the full life-cycle for all batteries (i.e. industrial, automotive, electric vehicle and portable) in the EU and US markets.

Within the whole chain, industrial suppliers will take responsibility for sourced materials, with restricted use of hazardous substances, minimum required content of recycled materials, carbon footprint, performance and durability and labeling, as well as meeting collection and recycling/reuse targets. The overall process is very complex and both alliances have developed a standardized process, of which the Digital Product Passport is the ultimate representation.

From concept to practice

As we move forwards, the Digital Product Passport has started to become a reality and, as presented in March 2022 by the EU Commission as part of its Circular Economy Action Plan 'Ecodesign for Sustainable Product Regulation' (ESPR), the DPP will cover all stages of the value chain; it will be continuously updated and will follow the product throughout its life cycle (Figure 02). Also worth mentioning, the EU Commission and the U.S. Department of Energy (DOE) have announced support for a collaboration between the European Battery Alliance and the United States. The Li-Bridge alliance is commited to accelerating the development of robust supply chains for lithium-ion and next generation batteries, including the critical raw materials segments. Bolstering the clean energy economy and strengthening the battery value chain is a top priority for both the European Union and the United States.

Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock) Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock) |

Europe on April 25 2022, a consortium of German world-class leaders and market drivers from industry and science combined their forces, launching the Battery Pass to support EU circular battery data. A technological feature of the project is the provision of a comprehensive solution for securely sharing information and data across different organizations and value-chain participants in the field of traction batteries, based on mandatory standard datasets and an interoperable technical implementation approach required to meet the EU regulation.

In the United States in October 2022, the Global Battery Alliance announced a major milestone with the publication of the Greenhouse Gas rulebook as the first indicator for the Battery Passport, consisting of:

- A global reporting framework to govern rules around measurement, auditing, and reporting of ESG parameters across the battery value chain.

- A digital ID for batteries containing data and descriptions about the ESG performance, manufacturing history, and provenance as well as advancing battery life extension and enabling recycling.

- Harmonizing of digital systems collaborating across the value chain to report data into the battery passport.

- A digital platform that will collect, exchange, collate and report data among all authorized lifecycle stakeholders to advance a sustainable value chain for electric vehicle (EV) and stationary batteries. It will transparently report progress towards global goals along the battery value chain to inform policy-making for governments, the civil society, and to develop performance benchmarks (Figure 03).

- A quality seal for batteries (based on the data reported into the platform) to facilitate responsible purchasing by consumers.

Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock) Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock) |

Those examples reflect the high engagement from the battery industry to finalize the implementation of the DPP, which will be used as a business model for other power electronics industries.

What is the next step for DDP and power electronics?

As for the battery industry, in 2017 Powerbox participated in a Think Tank about the future evolution of the power supply industry to reduce waste and to become part of a project at that time, the Regulation on Ecodesign for Sustainable Products. In a White Paper: 'Will the power supply industry adopt the cradle-to-cradle business model?' PRBX shared ideas on what could become the norm (Figure 04).

Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX) Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX) |

Although we are probably a few years away from the power supply industry adopting the DPP, this trend is something to be aware of and to keep in mind and it could happen faster than we may believe. Be ready for it!

References:

Powerbox (PRBX):

https://www.prbx.com/

EU Green Deal: New proposals to make sustainable products the norm and boost Europe's resource independence

https://ec.europa.eu/commission/presscorner/ detail/en/IP_22_2013

The Ecosystem Digital Product Passport (CIRPASS)

https://www.digitaleurope.org/digital-product-passport/

European Battery Alliance

https://www.eba250.com/

The EU Battery Pass

https://thebatterypass.eu/

The USA Global Battery Alliance

https://www.globalbattery.org/

LI-Bridge

https://www.anl.gov/li-bridge

Will the power supply industry adopt the cradle-to-cradle business model?

https://www.prbx.com/literature/white-papers/#WP012

Provided by Patrick Le Fèvre

Chief Marketing and Communications Officer, Powerbox