The Summer Edition of the EPSMA Newsletter is now available here.

Other news of interest

Twenty years ago, the adoption of the Restriction of Hazardous Substances Directive 2002/95/EC (RoHS 1) was one of the driving forces mandating the electronics industry to look for alternatives to replace the tin-lead eutectic alloy which had been used for decades for soldering purposes. Since then many regulations have sprung up restricting the use of hazardous substances, and we are familiar with RoHS, REACH, TSCA and others. In addition, growing concerns about long term sustainability and optimization of natural resources have motivated governments, institutions and industry to consider how to develop a circular business model, including elements from the cradle-to-cradle concept, and to define an optimum way to trace a product from its origin, its content, its compliance to environmental regulations, its reparability or final disposal and recycling. This materialized in March 2022 by the European Commission as part of the EU Green Deal, and was followed by similar initiatives in the US. But what is it about?!

Here comes the Digital Product Passport

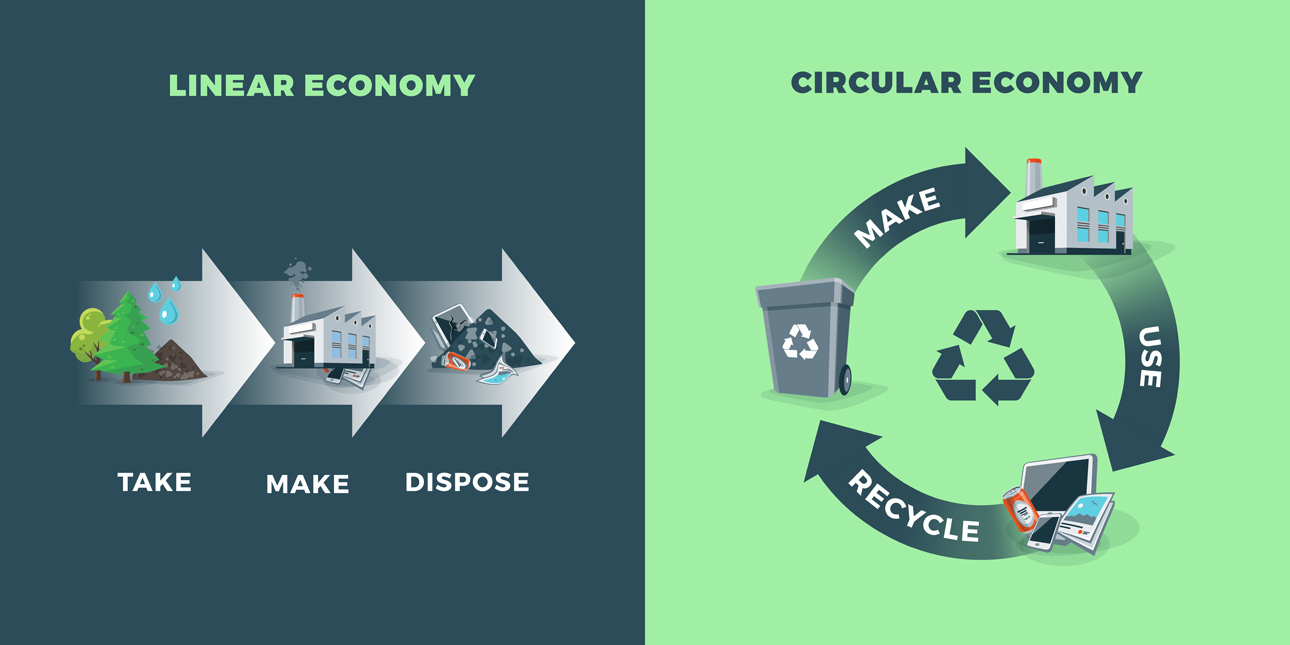

After 10 years of local initiatives, the European Commission presented a package of proposals as part of the European Green Deal to make sustainable products the norm in the EU, moving away from the conventional linear economy by boosting circular business models and empowering consumers for the green transition (Figure 01), including the so called Digital Product Passport (DPP).

Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock) Figure 01 - European Union moving from conventional linear economy to circular business model (PRBX/ petovarga/Shutterstock) |

At this point you may question what this has to do with power electronics and how the power supply community may be affected by this new requirement? Where is the threshold between a Point-of-Load, a multi kilowatts power supply or even an Electrical Vehicle? Which power electronics segment will have to comply with the DPP? Read on to better understand and debug what is DPP.

Having the whole life cycle in mind!

The proposal for a Regulation on Ecodesign for Sustainable Products addresses product design, which determines up to 80% of a product's lifecycle environmental impact. It sets new requirements to make products more durable, reliable, reusable, upgradable, reparable, easier to maintain, refurbish and recycle, and energy and resource efficient. In addition, product-specific information requirements will ensure that consumers are knowledgeable on the environmental impact of their purchases.

All regulated products will have Digital Product Passports making it easier to repair or recycle them and to facilitate the tracking of substances of concern along the supply chain. The aim of the passport is to provide producers and other key supply chain actors, as well as consumers and market surveillance authorities, with relevant information for ensuring the sustainable management of products. If well designed, and if aligned with existing industry initiatives, these Digital Product Passports could help to promote the circular economy and circular business models. This may sound quite hypothetical and even complex but let's consider a practical example with the booming energy storage segment and batteries.

The battery industry showing the way!

Since 2006 batteries and waste batteries have been regulated within the EU under the Batteries Directive (2006/66/EC). Though driven by electric transport and energy storage the demand for batteries has increased rapidly and is set to increase 14 fold by 2030. Such global exponential growth in the demand for batteries will lead to an equivalent increase in demand for raw materials, hence the need to minimize their environmental impact.

With high levels of concern for the long term sustainability of the battery industry, in 2017 two major initiatives took place in Europe and the USA. Both of these were similarly aimed: to develop an innovative, competitive and sustainable battery value chain in Europe and the USA with high regards for the environment and society.

In Europe on October 11, 2017, the European Commission hosted auto, chemical and engineering executives in Brussels to strengthen battery manufacturing in the EU and to develop a European ecosystem to reduce dependency and risk in the supply chain of what will become the heart of energy transition and mass electrification. This was followed by the launch of the European Battery Alliance (EBA) as part of Europe's clean and digital transition and a key enabling technology, essential to the automotive sector's competitiveness.

In the USA, in the same year, a public-private collaboration platform was founded at the World Economic Forum to help establish a sustainable battery value chain by 2030, The Global Battery Alliance (GBA).

It can be said that 2017 has been the EU/USA cornerstone for the battery industry setting the basic principles of what will become the DPP and a completely new way of working, integrating the full life-cycle for all batteries (i.e. industrial, automotive, electric vehicle and portable) in the EU and US markets.

Within the whole chain, industrial suppliers will take responsibility for sourced materials, with restricted use of hazardous substances, minimum required content of recycled materials, carbon footprint, performance and durability and labeling, as well as meeting collection and recycling/reuse targets. The overall process is very complex and both alliances have developed a standardized process, of which the Digital Product Passport is the ultimate representation.

From concept to practice

As we move forwards, the Digital Product Passport has started to become a reality and, as presented in March 2022 by the EU Commission as part of its Circular Economy Action Plan 'Ecodesign for Sustainable Product Regulation' (ESPR), the DPP will cover all stages of the value chain; it will be continuously updated and will follow the product throughout its life cycle (Figure 02). Also worth mentioning, the EU Commission and the U.S. Department of Energy (DOE) have announced support for a collaboration between the European Battery Alliance and the United States. The Li-Bridge alliance is commited to accelerating the development of robust supply chains for lithium-ion and next generation batteries, including the critical raw materials segments. Bolstering the clean energy economy and strengthening the battery value chain is a top priority for both the European Union and the United States.

Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock) Figure 02 - Digital Product Passport in circular economy (PRBX/ Dejan Popovic/Shutterstock) |

Europe on April 25 2022, a consortium of German world-class leaders and market drivers from industry and science combined their forces, launching the Battery Pass to support EU circular battery data. A technological feature of the project is the provision of a comprehensive solution for securely sharing information and data across different organizations and value-chain participants in the field of traction batteries, based on mandatory standard datasets and an interoperable technical implementation approach required to meet the EU regulation.

In the United States in October 2022, the Global Battery Alliance announced a major milestone with the publication of the Greenhouse Gas rulebook as the first indicator for the Battery Passport, consisting of:

- A global reporting framework to govern rules around measurement, auditing, and reporting of ESG parameters across the battery value chain.

- A digital ID for batteries containing data and descriptions about the ESG performance, manufacturing history, and provenance as well as advancing battery life extension and enabling recycling.

- Harmonizing of digital systems collaborating across the value chain to report data into the battery passport.

- A digital platform that will collect, exchange, collate and report data among all authorized lifecycle stakeholders to advance a sustainable value chain for electric vehicle (EV) and stationary batteries. It will transparently report progress towards global goals along the battery value chain to inform policy-making for governments, the civil society, and to develop performance benchmarks (Figure 03).

- A quality seal for batteries (based on the data reported into the platform) to facilitate responsible purchasing by consumers.

Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock) Figure 03 - Battery Digital Passport Example (PRBX/Chesky/Shutterstock) |

Those examples reflect the high engagement from the battery industry to finalize the implementation of the DPP, which will be used as a business model for other power electronics industries.

What is the next step for DDP and power electronics?

As for the battery industry, in 2017 Powerbox participated in a Think Tank about the future evolution of the power supply industry to reduce waste and to become part of a project at that time, the Regulation on Ecodesign for Sustainable Products. In a White Paper: 'Will the power supply industry adopt the cradle-to-cradle business model?' PRBX shared ideas on what could become the norm (Figure 04).

Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX) Figure 04: Will the power supply industry adopt the cradle-to-cradle business model (PRBX) |

Although we are probably a few years away from the power supply industry adopting the DPP, this trend is something to be aware of and to keep in mind and it could happen faster than we may believe. Be ready for it!

References:

Powerbox (PRBX):

https://www.prbx.com/

EU Green Deal: New proposals to make sustainable products the norm and boost Europe's resource independence

https://ec.europa.eu/commission/presscorner/ detail/en/IP_22_2013

The Ecosystem Digital Product Passport (CIRPASS)

https://www.digitaleurope.org/digital-product-passport/

European Battery Alliance

https://www.eba250.com/

The EU Battery Pass

https://thebatterypass.eu/

The USA Global Battery Alliance

https://www.globalbattery.org/

LI-Bridge

https://www.anl.gov/li-bridge

Will the power supply industry adopt the cradle-to-cradle business model?

https://www.prbx.com/literature/white-papers/#WP012

Provided by Patrick Le Fèvre

Chief Marketing and Communications Officer, Powerbox

AdaClock provides strategic technical marketing which includes:

Insights for Power Management

- Identify company & product strengths and weaknesses

- Market & product trends and analysis

- Identify market disruptions & new markets/customers

- Market entry strategies

- Competitive intelligence

- Strategies for defending current markets

- Specific analytical insights into the Power Supply in a Package (PSiP) & Power Supply on a Chip (PwrSoC) market

Results Oriented

- Defining products that stand out from the competition and command high margins

- Anticipate customers' expectations.

- Identify potential partners, advocates & acquisition targets to strengthen market position.

Benefits of using AdaClock

- Technical marketing expertise without overhead.

- Objective perspective from the outside.

- Ability to talk with customers & competitors without association to your company.

- Scalable resources depending on scope and timing.

Provided by Ada Cheng, Marketing Consultant, AdaClock.

Hong Kong Applied Science and Technology Research Institute (ASTRI) was founded by the Government of the Hong Kong Special Administrative Region in 2000 with the mission of enhancing Hong Kong's competitiveness through applied research. ASTRI's core R&D competence in various areas is grouped under four Technology Divisions: Trust and AI Technologies; Communications Technologies; IoT Sensing and AI Technologies and Integrated Circuits and Systems. It is applied across six core areas which are Smart City, Financial Technologies, Re-Industrialization and Intelligent Manufacturing, Digital Health, Application Specific Integrated Circuits and Metaverse.

Over the years, ASTRI has nurtured a pool of research, I&T talents and received numerous international awards for its pioneering innovations as well as outstanding business and community contributions. As of 2021/22, ASTRI has transferred almost 1,250 technologies to the industry and has been granted over 1,000 patents in the Mainland, the US, and other countries.

What We Offer

As a Hong Kong R&D Centre, one of ASTRI's important goals is to help customers harness business opportunities from the thriving technology market and increase their competitive strengths. Customers and partners can improve their efficacy by drawing on ASTRI's expertise and research achievements.

- Technology Transfers

ASTRI has a rich portfolio of commercially viable technologies readily available for market deployment. There were close to 1,250 cases of technology transfers conducted through research contract, technology licensing and other forms of partnership, generated a total of over HK$450 million income received from industry.

- R&D Professionals

ASTRI has teams of brilliant researchers led by competent professionals, many of whom are prominent technologists in their respective fields. ASTRI has 600 staff, with 23% holding PhD degrees and more than 56% holding Master's degrees.

- Intellectual Properties

ASTRI has produced a volume of home-grown and patent-protected technologies. Since its establishment, the institute has filed more than 1,300 patents and more than 1,000 of which have already been granted in US, China and worldwide.

Provided by Dr. Ziyang GAO, Associate Senior Director of Integrated Circuits and Systems, ASTRI

Four members of the Board of Directors are elected at the PSMA Annual Meeting held every year, usually held during the APEC conference. Each Director serves a three-year term and is eligible to be reelected for one additional term.

In this issue we would like to introduce you to Brian Zahnstecher who will complete his second term at the 2023 PSMA Annual Meeting.

Brian Zahnstecher

Principal, PowerRox

Brian Zahnstecher sits on the Power Sources Manufacturers Association (PSMA) Board of Directors, is Co-founder & Chair (Emeritus) of the PSMA Reliability Committee, Co-chair of the PSMA Energy Harvesting Committee, Co-founder & Co-chair of the EnerHarv workshop. Brian is a Sr. Member of the IEEE, Chair (Emeritus) of the IEEE SFBAC Power Electronics Society (PELS), IEEE PELS North America Regional (R1-3) Chair, and is the Principal of PowerRox. He Co-chairs the IEEE Future Directions (formerly 5G) Initiative webinar series and is the founding Co-chair of the IEEE 5G Roadmap Energy Efficiency Working Group and has lectured on this topic at major industry conferences.

Brian previously held positions in power electronics with industry leaders Emerson Network Power (now Advanced Energy), Cisco, and Hewlett-Packard. He has been a regular contributor to the industry as an invited keynote speaker, author, workshop participant, session host, roundtable moderator, and volunteer. He has nearly 20 years of industry experience and holds Master and Bachelor degrees from Worcester Polytechnic Institute.

Provided by Brian Zahnstecher, Principal, PowerRox

Building on the succ ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference (APEC) in March of 2022, PSMA continued efforts to increase engagement by participating in both events during the 2022 Energy Conversion Congress & Expo (ECCE) held October 9-13 in Detroit, MI. Aside from contributing participants and messaging to support event objectives, PSMA provided financial support as a full co-sponsor as part of a concerted outreach effort to promote diversity, inclusion, and early development in the industry.

ess of participation in the Young Professionals (YP) social event and Women in Engineering (WiE) roundtable breakfast at this year's Applied Power Electronics Conference (APEC) in March of 2022, PSMA continued efforts to increase engagement by participating in both events during the 2022 Energy Conversion Congress & Expo (ECCE) held October 9-13 in Detroit, MI. Aside from contributing participants and messaging to support event objectives, PSMA provided financial support as a full co-sponsor as part of a concerted outreach effort to promote diversity, inclusion, and early development in the industry.

The YP social event was held the evening of Tuesday, October 11, 2022, at the Grand Truck Pub not far from Huntington Place Convention Center, where ECCE was held. The event was co-sponsored by the IEEE Power Electronics Society (PELS) YP group and the IEEE Industry Applications Society (IAS) along with PSMA. As the photo shows, this was a standing-room-only event with lively discussions amongst the leaders in both academia and industry with many students and young professionals. Whether the young people were from the North America, Europe, Asia, Africa, or otherwise, the most interest seemed to be in seeking meaningful internships and/or interaction with industry professionals in a target area of focus.

The following morning, Wednesday, October 12, 20 22, started bright and early with the WiE Roundtable Breakfast held n the main hallway of the Huntington Place Convention Center. Unlike the free-for-all format of the previous evening's social event, this event was more structured with many tables each representing a different area of focus that were led by table leaders and mentors from the respective area. PSMA was represented by Greg Evans & Stephanie Watts-Butler supported the event. Several attendees coming to the PSMA table were not previously familiar with the organization and expressed gratitude for having this industry-focused component as part of the overall ECCE program to enhance their industry involvement, and hopefully help to accelerate their own careers. The participants also seemed interested to learn more about getting involved in PSMA activities and programs and were interested in learning more about APEC and other PSMA-sponsored/organized events.

22, started bright and early with the WiE Roundtable Breakfast held n the main hallway of the Huntington Place Convention Center. Unlike the free-for-all format of the previous evening's social event, this event was more structured with many tables each representing a different area of focus that were led by table leaders and mentors from the respective area. PSMA was represented by Greg Evans & Stephanie Watts-Butler supported the event. Several attendees coming to the PSMA table were not previously familiar with the organization and expressed gratitude for having this industry-focused component as part of the overall ECCE program to enhance their industry involvement, and hopefully help to accelerate their own careers. The participants also seemed interested to learn more about getting involved in PSMA activities and programs and were interested in learning more about APEC and other PSMA-sponsored/organized events.

In summary, this was PSMA's initial foray into the world of ECCE and it helped meet the key objectives of increased engaging with the next generation of power professionals. These outreach efforts made many aware of the numerous resources and programs provided be PSMA, and its vast, industry membership base. This was also a chance for PSMA to expand our engagement beyond the traditional focus of APEC and other PSMA sponsored events. ECCE has a far more academic audience than APEC, and the extra injection of industrial support and mentoring seemed to be well-received and even an unexpected boon to some. Hopefully, 2022 becomes the first of many years of events co-sponsored by PSMA and IEEE societies at key conferences (i.e. APEC & ECCE) providing opportunities for deeper engagement and collaboration between PSMA, its membership and most importantly, the pipeline of students and YPs that will eventually be running all these activities in the future.

Provided by Brian Zahnstecher, PSMA Industry-Education Committee Member

KPIs-Metrics that Matter

Building on the foundational work that Trifon Liakopoulos began during his tenure as PSMA Vice President, I have taken the role within the Executive Committee to continue to focus on identifying the KPIs – Key Performance Indicators – that are actionable and will help to improve the performance and effectiveness of the organization. Some of the areas we have begun to measure related to membership are the annual growth rate, member retention rates, and market share of members compared to the number of potential member organizations in the industry. As an organization it is crucial that we continue to grow our membership and to provide significant benefit to our existing members to encourage retention. We need a deep understanding of what member companies value from their engagement with PSMA and to continue to invest in those areas.

It is also critical to monitor the impact of the special projects and events offered to our members and the industry at large. We are establishing KPIs to measure the effectiveness of these activities in terms of member interest and usage, new member recruitment, and revenue impact. Since we are a volunteer driven, non-profit organization, we need to spend our revenue and human resources on the activities that provide the most benefit to our audience and the largest return on investment to our organization.

Lastly, we have established baseline metrics related to website traffic and visitor behavior with a goal to improve the effectiveness of the website to raise awareness, provide valuable content, and increase membership. The website is our most public marketing asset, developing measurable KPIs will help to focus our efforts on providing content that is viewed as relevant and vital to our audience.

KPIs will provide actionable feedback on the success of current activities and identify opportunities for improvement. The Executive Committee will rely on the support and efforts of all members to define, measure, and implement actions to improve the effectiveness of our activities and enhance our efforts to attract new members. We encourage all members to provide feedback, thoughts, and new ideas so we can continue to learn and grow as an organization.

Please feel free to contact me or any of the executive team members with your thoughts and inputs. We would love to hear from you!

-Renee Yawger, PSMA Vice President

The Power Sources Manufacturers Association (PSMA) announces a series of webinars as a lead-up to the next edition of the PSMA Power Technology Roadmap (PTR). The webinar series, organized by the PSMA Power Technology Roadmap Committee, will feature invited experts from different fields to offer a range of technological perspectives. In addition to setting the groundwork and providing input for the next PTR, the webinars will give participants access to expert opinions on technology trends and include a question and answer session at the end of each session.

The Power Sources Manufacturers Association (PSMA) announces a series of webinars as a lead-up to the next edition of the PSMA Power Technology Roadmap (PTR). The webinar series, organized by the PSMA Power Technology Roadmap Committee, will feature invited experts from different fields to offer a range of technological perspectives. In addition to setting the groundwork and providing input for the next PTR, the webinars will give participants access to expert opinions on technology trends and include a question and answer session at the end of each session.

As in previous seasons, the webinar series will include a number of highly regarded industry and academic experts covering a variety of topics covering components, systems, packaging and applications. The series began on July 28 with a presentation by Victor Veliadis of PowerAmerica "SiC Power Technology Status and Barriers to Overcome." A second webinar was held on August 25 presented by Professor Mike Ranjram of Arizona State University "Coupled Electronic and Magnetic Systems for High Performance Power Electronics." Webinars are scheduled for September and beyond covering a wide range of topics including horticultural lighting, the benefits of GaN in BLDC Motor Drives and many other topics.

Webinars are tentatively scheduled to be held every other Thursday from 10:00-11:00 a.m. US Central Time. For updates to the schedule and news of webinars that will be added, please visit: www.psma.com/technical-forums/roadmap/news-events and follow us on LinkedIn and Twitter. To join the PSMA mailing list to receive invitations to all upcoming webinars, sign up at www.psma.com/webforms/psma-email PSMA gratefully acknowledges the generous support provided to the 2021-22 PTR series by the following underwriters: Gold - RECOM Power GmbH; Silver - Applied Materials, Infineon, Wolfspeed, Würth Elektronik. If your company is interested in underwriting the webinars in 2023, please contact the PSMA Office at power@psma.com.

The Power Technology Roadmap provides a consolidated outlook of trends in power conversion technology for the next two to five years. The trends provided in the report are intended to give a broad outlook of the power conversion technologies, components and applications. The complete Roadmap document has been published every two or three years, incorporating the content of the Roadmap Webinars Series conducted over the months prior to publication. The other content for the report is sourced from a wide range of recognized industry experts and comprises write-ups about trends in components, applications, emerging technologies and university research. It also includes a comprehensive projection of key metrics evolution in four selected power conversion technologies (ac-dc front-end power supplies, ac-dc external power supplies, isolated dc-dc converters and non-isolated dc-dc converters).

Conor Quinn of Advanced Energy and Dhaval Dalal of ACP Technologies, Power Technology Roadmap Committee Co-chairs, stated; "The PTR webinars provide a window into technology trends and the presentations are unique in terms of their diversity of perspectives, commercial-free tone and the opportunity they offer for the audience to interact with industry experts. We are always looking to enrich and expand our panel of webinar presenters and we welcome suggestions and proposals from prospective speakers." Joe Horzepa, PSMA Executive Director, added that the Committee "welcomes and invites subject matter experts who are willing to actively participate and contribute to the development of the next PSMA Power Technology Roadmap to contact the PSMA Association Office at power@psma.com."

Power supplies are everywhere, an essential part of all electronic equipment. Whether powered by battery or from the grid, there are as many power solutions as there are applications. From body sensors powered by harvested energy to high power systems for medical imageries such as MRI, medical power supplies, all have a common requirement to be safe, reliable and energy efficient. While the large majority of medical equipment requires conventional power supplies compatible with their operating environment, in effect running a marathon by delivering steady power day after day during their lifetime, there are certain categories of applications that require a power supply able to deliver peak power, either occasionally or repetitively. For these applications medical equipment manufacturers must consider a number of parameters to ensure that the power supply they select will be able to not only run a marathon but in certain specific applications be able to perform a sprint race without compromising safety, performance or reliability.

What to consider when a marathon requires sprint race performance?

While it is assumed for medical equipment manufacturers that a power supply must comply with safety standards (EN/IEC 60601-1), the output performance is very much dependent on the final equipment's load behavior. While in monitoring and supervising systems the power consumption remains relatively stable and easy to predict, in medical equipment such as medicalized beds, infusion pumps, assisted patient ventilation that includes DC motors, and electromechanical-switches behaving as inductive or capacitive loads, the power supply may at times have to deliver extra power for a period of few milliseconds to seconds (Figure 01). Though the duration time for peak power may be considered short compared to a normal operating time, it still needs to be seriously considered to avoid costly surprises.

Figure 01 – Infusion pumps and typical peak load behavior (Source: PRBX/ Superstar-Shutterstock) |

In addition to the output voltage and power, the type of load will determine what factors are important for the system designer to consider. There are many possibilities and in some equipment the main power supply could power a variety of systems and sub-systems with different load profiles which is obviously more complex to address. To simplify, we will list four basic types of loads: inductive, capacitive, constant current, and nonlinear resistive. Each of them has a specific behavior requiring attention when selecting a power supply for each such applications.

Loads types in short:

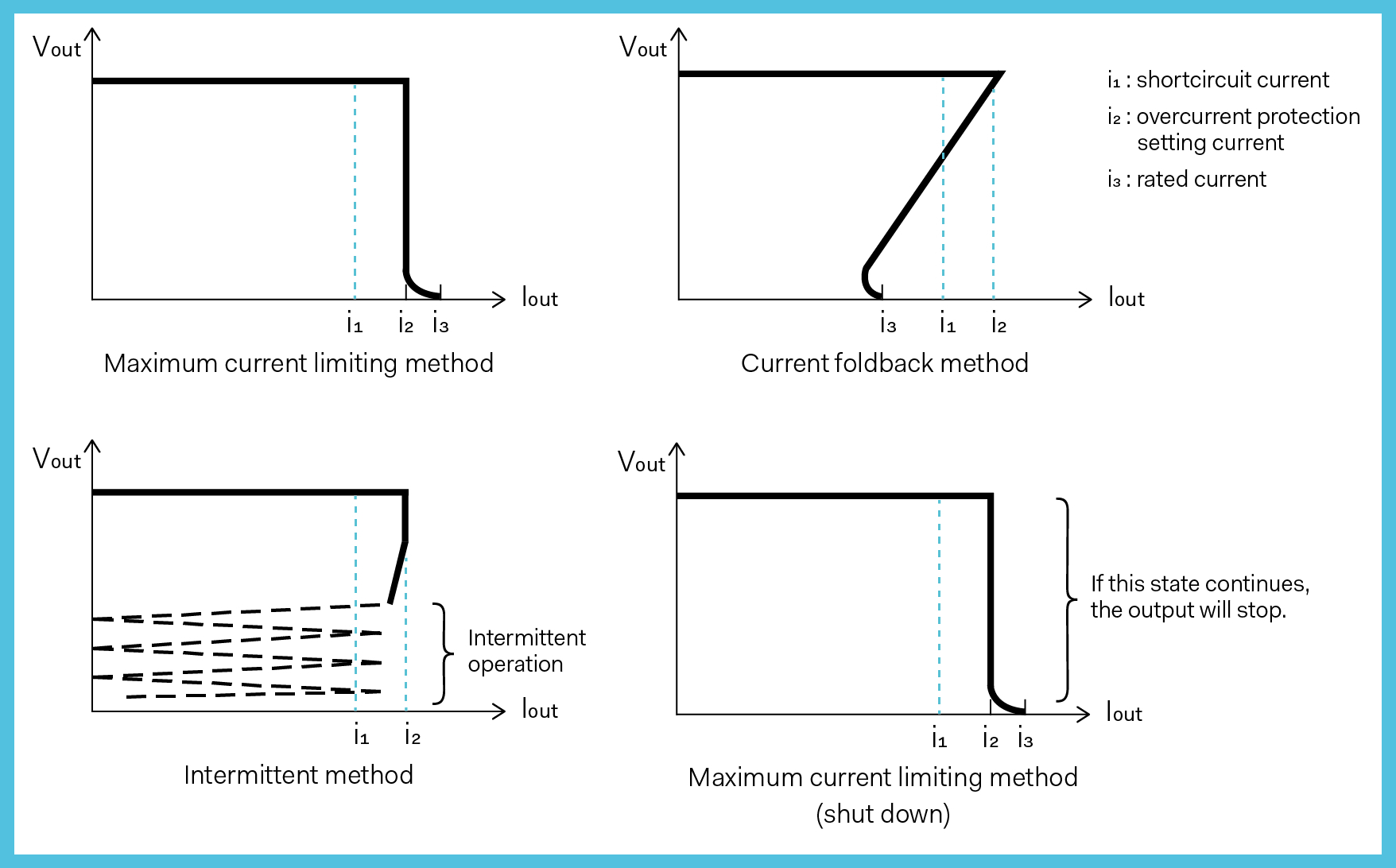

Inductive load: Loads such as motors and electromagnetic switches (e.g., relays, magnet switches) with an inductive characteristic are referred to as inductive loads. At the moment of applying a voltage to a DC-motor, a current multiple times the rated value will flow through the load; while at the moment of cutting the voltage off, due to the inductive component of the load, a voltage of counter electromotive force E= -L× (di / dt) will be generated. Generally, when applying a voltage to an inductive load the power supply can sustain the energy required by the peak demand only up the limit of its overcurrent protection (OCP) function (Figure 02). Exceeding the limit, even if only for a very short time, can cause the power supply to stop. This is the reason why the peak load must be well defined in order to select an appropriate power supply with an overcurrent protection that allows the surge power for a definite time and sequence. Also, when turning the output voltage off, due to the counter electromotive force generated (in most cases, it is absorbed by the electrolytic capacitors in the power supply), the overvoltage protection circuit of the power supply may be triggered, and the power supply cease output. In this case measures such as including a reverse voltage protection diode should be exercised.

Capacitive load: A load with a capacitance component is called a capacitive load. For example, the capacitors inserted for the purpose of reducing the ripple voltage of the power supply, and capacitors used for coping with peak loads, etc. For this kind of load, at the moment of applying a voltage a very large charging current ipeak = (V/R) with R being the (parasitic) series resistance, will flow due to there being no charge in the capacitor. Although the power supply can detect and control the output voltage, if a large value capacitor (over several tens of thousands of microfarads) is inserted into the output side, such control may not be able to realize what is happening, and the output voltage may become unstable. It is important for system designers to consider the total amount of capacitance installed in their equipment and to verify the power supply's ability to deliver the required peak energy needed to efficiently charge the load which in some applications could be several Farads.

Figure 02 – Typical overcurrent protection curves (Source: PRBX/ COSEL) |

Constant current load: A load where the current stays constant although the load voltage varies is called a constant current load, an example being LED lighting in surgical theaters. It is important to consider the type of overcurrent protection built into the power supply. If for example the overcurrent protection characteristic of the power supply is a current fold back type, the output voltage may not be able to rise (Figure 02). This is because the output voltage stabilizes on the drooping line of the overcurrent protection characteristic of the power supply from applying a voltage to reaching the rated voltage. Generally, by changing the overcurrent protection characteristic to a maximum current limiting type the problem can be solved.

Non Linear Resistive: Some equipment uses heating elements or lamps with filaments where the resistance changes when current flows through it. Though this warm up phase with a monotonic resistance change might only last for a short time, for the power supply it may look like a constant current exceeding the threshold value for its built-in overcurrent protection.

Overcurrent protection is a very important part of a power supply. It guarantees the power unit in the case of an excess power situation that may occur accidentally or as result of an equipment failure, will protect the equipment and will eventually flag the fault by way of a signal to the operator, e.g. a LED or a signal transmitted by the communication BUS.

Overcurrent protection overview

As previously explained, when the output current/power exceeds a defined limit, several types of damage could occur within the power supply or in the equipment being powered. Besides preventing the current from exceeding a rated value, the protection circuit also plays the role of limiting short circuit current. Depending on the type of application and specific system requirements, when OCP is activated a number of effects may result, the output could be switched off permanently with a manual reset, switched off temporarily with an automatic reset, or behave as a fixed, but safe level constant current (Figure 02).

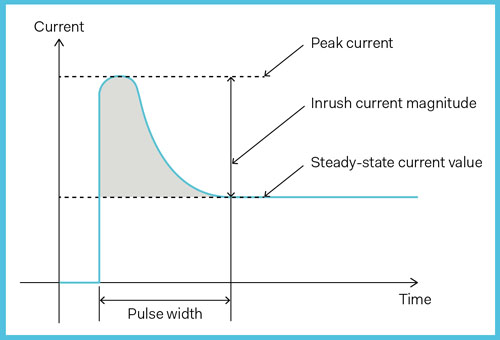

Figure 03 – Peak current at startup when charging capacitors (Source: PRBX) |

When a power supply or an electrical device is turned on, high initial current flows into the load, ramping up until it reaches a peak value. The main reason for this initial peak is to charge the large decoupling or smoothing capacitors within the power supply and final equipment. During this sequence, as the capacitors charge or devices come out of a cold state, the current increases very quickly from zero, rising all the way to the peak current and then decreasing gradually to the steady state current (Figure 03). During this period the power supply must deliver enough energy to charge the capacitors, and supply the required power to the load without activating the over-current protection (OCP) thus shutting down the output. Also, some loads might initially behave as a short-circuit and require the power supply not to go into protection mode. To accommodate this start-up sequence, power supplies are designed to allow a certain level of overcurrent, and it is common to set the OCP threshold at around 110% of the maximum rated value.

110% is good enough for the vast majority of applications though in the case of demanding medical equipment requiring peak power levels in the range of 200-300% for seconds, 110% will not suffice, requiring a power supply designed not only to deliver a high peak power, but to guarantee the highest reliability during the overall lifetime of the final equipment.

Running a marathon at sprint performance levels!

A simple way to guarantee the power supply will deliver enough energy when extra surge power is required is to choose a power unit rated for the maximum power required during the peak demand. For example, if the maximum steady power required by an apparatus is 500W and the peak is 1000W, then taking into consideration the operating conditions e.g., input voltage, environmental temperature, derating, etc., the system designer could consider a 1200W power supply as the most suitable solution.

This seems to be obvious, but is overkill when the peak is only happening occasionally. For example when a DC motor is activated for positioning a patient's bed then switched off and the power supply is again only powering the control system. Similarly this would be overkill for systems requiring repetitive peak loads for a limited time compared to steady state power.

Choosing a power supply for peak load applications requires one to evaluate the operating conditions during the lifetime of the equipment, and to take into consideration all aspects including size, weight and price. Buying a 1200W power supply, when peak load represents only a limited portion of the operation, might not be the best option.

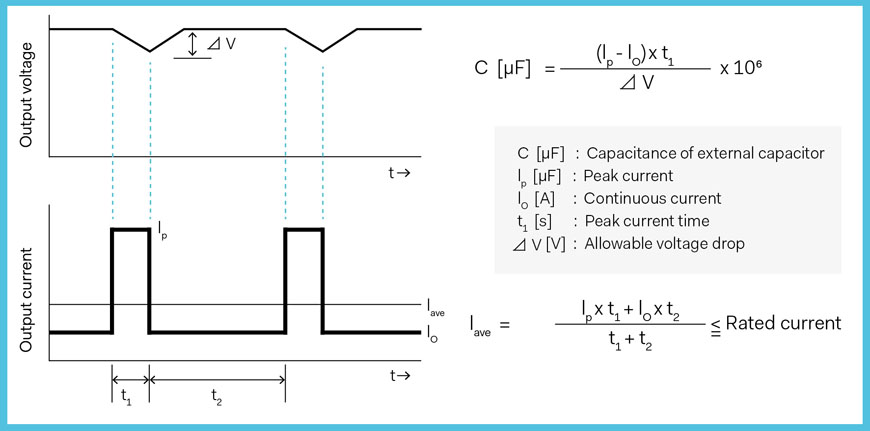

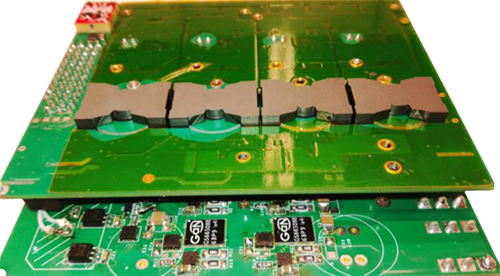

Power supply manufacturers have developed power solutions able to deliver significant extra power in the range of twice nominal, or even more than the maximum rated, for a significant duration. This requires the power unit to be designed to host enough capacitors (Figure 04) but also to have a power-train able to sustain repetitive peak demands without over-heating or adversely affecting reliability.

Figure 04 – Design equation to guarantee output capacitors to sustain required peak energy (Source: PRBX) |

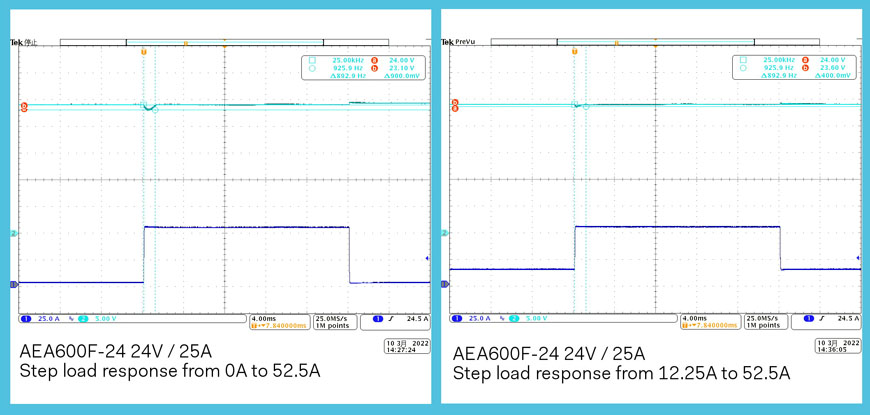

As an example, consider the output voltage behavior of the COSEL 600W AEA600F series (Figure 05) when applying a peak load to the output. The tested product is a 600W rated power unit, delivering 24V at a nominal current of 25A. As presented in Figure 06, the power-train and output capacitors have been selected to sustain a peak power twice nominal for a duration of 1000 milliseconds. Two conditions are represented in Figure 06: From no load to 52.5A peak, and from 12.25A half-load to 52.5A peak. In both conditions, the voltage remains within the specified limits, and OCP is not shutting down the output.

Figure 05 – COSEL 600W power supply for medical applications with peak load capacity up to 300% (Source: PRBX/COSEL/WHYFRAME-Shutterstock) |

Figure 06 – COSEL AEA600F peak load test in two conditions (0 to 200% and 50% to 200% load) (Source: PRBX/COSEL) |

Conclusion

Running a marathon with sprint-race performance levels in medical power supplies is a reality, and while the great variety of applications require different types of power supplies, technology is making it easier for system designers to choose the right products for their applications. This is without mentioning the fantastic opportunities brought about by new technologies such as Wide Band Gap semiconductors, Supercapacitors, and digital control coming to the next generation of power supplies, and making power designers' lives so exciting.

References:

Powerbox (PRBX):

https://www.prbx.com/

|

Provided by Patrick Le Fèvre

|

|

At the APEC 2022 Plenary Session, John H. Scott, Principal Technologist, Power and Energy Storage, NASA Space Technology Mission Directorate presented a very interesting topic: 'On the Moon to Stay', covering the various aspects of power electronics that would be required to make that statement feasible. Space exploration has not only been a dream and a source of imagination, but also an amazing research area seeking to break 'unbreakable' limits, and in the processing providing benefits to many applications we are now using daily on planet Earth.

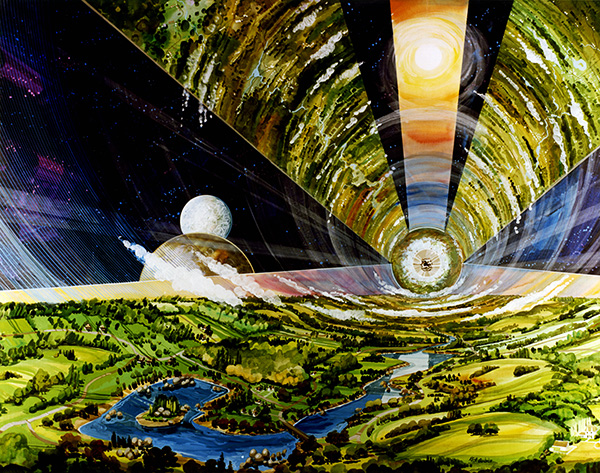

Figure 01 - O’Neill Cylinder interior - Painting by Rick Guidice (Source: PRBX/NASA)

Figure 01 - O’Neill Cylinder interior - Painting by Rick Guidice (Source: PRBX/NASA)

Taking humans first to the moon, later to Mars and who knows where to next, is far from being an easy job; making life possible and sustainable in such hostile environments is much more than just 'a challenge'. One example is how to feed the space explorers when they are so remote from planet Earth? When considering Mars, it would take 210 days and a significant cost and risk for a re-supply rocket to arrive, which is clearly not an optimum solution. Space farming has been part of that dream and we all remember the O'Neill Cylinder, designed by Princeton physicist Gerard K. O'Neill who published in 1974 an article in Physic Today: 'The Colonization of Space'. O'Neill's article and research fueled a number of sci-fi movies showing the huge rotating cylinder, hosting farms and lit by an artificial sun (Figure 01). We are not there yet, but on that basis the first humans to inhabit Mars may be considered farmers more so than astronauts! So how will power electronics contribute to make the dream a reality?

From Earth indoor farming to Space: Feeding 10 billion people on Earth

Let's start by looking at Earth. If we consider the latest estimation, Earth's population is expected to reach 10 billion by 2050. Simultaneously we are facing climate changes that could impact the complete food ecosystem and require significant modifications to the ways in which we produce and consume food.

Considering all the parameters and requirement to produce food with the highest respect for the environment, in 1999, Dr. Dickson Despommier with his students developed the idea of modern indoor farming, revitalizing the terms coined in 1915 by the American geologist Gilbert Ellis Bailey: "Vertical farming." We have all heard about it and even read articles about industrial buildings that were converted into vertical farms, but from the early days using fluorescent or halogen lighting to Solid State Lighting (SSL), there have been an amazing number of technological innovations that contribute to the effort to optimize the energy delivered to the plants for optimal growth. With these advances, the benefits of indoor farming multiplies. If we consider space utilization, 100 times more food could be produced per square meter compared to traditional agriculture, reducing water utilization by 90% and hazardous chemicals to none. Indoor farming is very attractive but to be really efficient such agriculture requires a very efficient lighting system (Figure 02).

Figure 02 - Solid State Lighting to grow vegetables in indoor farming (source PRBX / asharkyu-Shutterstock)

Figure 02 - Solid State Lighting to grow vegetables in indoor farming (source PRBX / asharkyu-Shutterstock)

Not all vegetables can grow with limited soil and nutrition by impregnation but for the ones compatible with this farming method, the results are impressive and can be further improved by using modern lighting technologies that are computer-controlled. This is very interesting area which for power designers to explore, combining advanced power electronics and modern agriculture, while keeping software in mind.

Since its introduction, indoor farming engineers conducted research to determine the spectrum and energy required by different plants to grow efficiently. From wide spectrum fluorescent or halogen lamps to narrower spectrum, the conventional lighting industry innovated a lot but these technologies are not flexible nor efficient enough to respond to the demand.

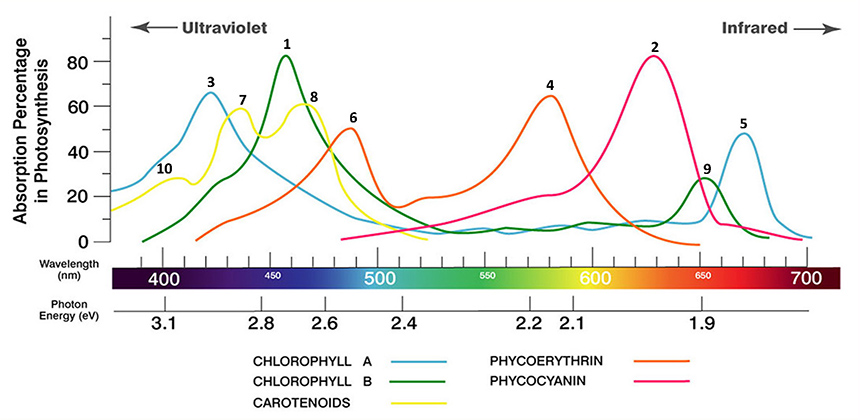

Figure 03 - The light spectrum to grow plants and vegetables typically starts at 450 nm (blue light) and goes through 730 nm (far red) (source PRBX)

Figure 03 - The light spectrum to grow plants and vegetables typically starts at 450 nm (blue light) and goes through 730 nm (far red) (source PRBX)

In Japan from 2005-2008, agronomical researchers experimented with different lighting methods to adjust spectrum and energy to specific plants. Researchers concluded that the optimal light spectrum to grow plants and vegetables typically starts at 450 nm (blue light) and goes through 730 nm (far red) (Figure 03). The Photosynthetic Photon Flux Density (PPFD) required ranges from 50 micromoles (µmol) for mushrooms up to 2,000 micromoles for plants like tomatoes and some flowers that thrive in full summer light (Figure 04).

Figure 04 - Light energy required ranges from 50 micromoles (µmol) for mushrooms up to 2.000 micromoles for light intensive plants (source PRBX/ barmalini - Shutterstock)

Agricultural experts advise that for optimal results different plants require different light spectra as well as differing light balances and intensities at different stages of growth, from seedling through harvest. This often results in the need for the artificial light to have a number of different spectra channels that are individually adjustable for intensity. Some crop growing practices combine different sources of lighting, including the use of UV flashes to prevent the development of parasites, requiring a power supply able to switch from constant voltage to constant current within a range from almost zero to the maximum (Figure 05). This specification for a power supply is very much what will be required for Space Farming, in addition to a power electronics architecture able to combat the effects of space radiation.

Bringing Earth farming to Space

As NASA plans long-duration missions to the Moon and Mars, a key factor is figuring out how to feed crews during their weeks, months, and even years in space. Food for crews aboard the International Space Station (ISS) is primarily prepackaged on Earth, requiring regular resupply deliveries. Now, while it is feasible for the ISS to be resupplied by cargo spacecraft, clearly it would be much more complicated and expensive to use this method on Mars, which is at an average distance of 220 million km (140 million miles) and more than 200 days traveling.

Figure 05 – COSEL power supply with multi-modes for voltage or current constant from max to near zero (Source PRBX/COSEL)

Figure 05 – COSEL power supply with multi-modes for voltage or current constant from max to near zero (Source PRBX/COSEL)

In 2015, NASA in association with the Fairchild Botanical Gardens in Miami began a project called 'Growing Beyond Earth' to define what plants would be suitable for autonomous space-farming. After a series of experiments which took into consideration the full development cycle, the variety of plants that were selected for further research included lettuces, mustard varieties, and radishes. These crops were first grown in a controlled lab on Earth, then in the ISS to study how plants are affected by the micro-gravity and other factors (Figure 06).

Figure 06 - NASA astronaut Peggy Whitson looks at the Advanced Astroculture Soybean plant growth experiment (Source: PRBX/NASA)(Source PRBX/NASA)

Figure 06 - NASA astronaut Peggy Whitson looks at the Advanced Astroculture Soybean plant growth experiment (Source: PRBX/NASA)(Source PRBX/NASA)

The 'Veggie' project included a large number of experimental factors such as "Pick-and-Eat Salad-Crop Productivity, Nutritional Value, and Acceptability to Supplement the ISS Food System (Veg-04A)" and included research on the optimum lighting conditions to grow plants. On the ISS, two light treatments with different red-to-blue ratios were tested for each set of crops to define light colors, levels, and horticultural best practices to achieve high yields of safe, nutritious leafy greens and tomatoes to supplement a space diet of pre-packaged food, and later for Moon or Mars farming. A number of reports have been released including 'Large-Scale crop production for Moon and Mars: Current gaps and future perspectives' published in February in 'Frontiers in Astronomy and Space Sciences' summarizing seven years of experimentation on Earth and in the ISS (Figure 07).

https://www.psma.com/HTML/newsletter/pics/prbxa_047_figure_07_space-far…" width="90%" />Figure 07 – Examples of Kennedy Space Center 8KSC) prior, current and future space crop production platforms selected and designed to lead to crop production units destined for the Moon or Mars (Source PRBX/NASA)

Considering the different varieties of plants that will be grown, and the distance and cost, the power supplies for space-farming will have to accommodate different power profiles combining constant current or constant voltage, peak power, and must also be energy efficient and small in size. That's in addition to specific constraints related to space, including immunity to radiation, operating temperature, shock and vibration.

The importance of optimizing the payload, the weight and size of everything is a big concern for space applications. For all applications, from low orbit satellites to out-of-space exploration, power supplies have been developed with very advanced technologies to make them smaller and energy efficient.

Wide Band gap (WBG) semiconductors in space applications have formed a part of many research projects, and it's worth mentioning the report presented by NASA, in 2018, at the (RADECS) conference in Gothenburg: 'Radiation and its Effects on Components and Systems'. This identified the strengths and weaknesses of WBG when exposed to radiation. The recent announcement about the newly funded national collaboration led by Penn State to better predict and mitigate radiation-induced damage of WBG semiconductors is interesting. The U.S. Department of Defense awarded the team a five-year, $7.5 million Defense Multidisciplinary University Research Initiative Award. This clearly shows the high level of importance of WBG in space applications and their contribution to the next step.

In parallel, the semiconductor industry is moving forward. One example is the new division and products for space applications launched by Efficient Power Conversion (EPC). For power designers, having access to COTS ruggedized GaN for space applications will reduce the development time and cost when developing power supplies for space applications (Figure 08).

Figure 08 – Efficient Power Conversion (EPC) ruggedized GaN FET for space applications and DC/DC converter (Source: PRBX/EPC)

Figure 08 – Efficient Power Conversion (EPC) ruggedized GaN FET for space applications and DC/DC converter (Source: PRBX/EPC)

Conclusions:

Although one of the biggest challenges to in-spaceship farming is sourcing enough water and nutrients and then cycling them as efficiently as possible, there are many other obstacles we don't have to grapple with on Earth that will need to be considered too, such as cosmic radiation, lack of an atmosphere, and low levels of light. From the 2015 'Growing Beyond Earth' project to current advances in 2022, a lot of progress has been made, contributing to a better understanding of space farming, as well as in power electronics. We are in the early stages of a whole new era in which Wide Bandgap semiconductors in power electronics will play an important role.

Exciting time for power designers, isn't it?!

References:

Powerbox (PRBX):

https://www.prbx.com/

The Colonization of Space – Gerard K. O'Neill, Physics Today, 1974

https://space.nss.org/the-colonization-of-space-gerard-k-o-neill-physics-today-1974/

Fairchild Botanical Garden

https://fairchildgarden.org/gbe/

Growing Beyond Earth

https://www.nasa.gov/feature/students-help-nasa-researchers-decide-what-plants-to-grow-in-space

NASA / RADEC 2018

Jean-Marie Lauenstein – NASA GSFC, Greenbelt, MD, USA

Wide-Bandgap Semiconductors in Space: Appreciating the Benefits but Understanding the Risks

Frontiers in Astronomy and Space Science

Large-Scale Crop Production for the Moon and Mars: Current Gaps and Future Perspectives

Published 04 February 2022 / doi: 10.3389/fspas.2021.733944

Efficient Power Conversion (EPC)

https://epc-co.com/epc

Applied Power Electronics Conference (APEC)

https://apec-conf.org/

Provided by

Patrick Le Fèvre

Chief Marketing and Communications Officer, Powerbox

The Power Sources Manufacturers Association (PSMA) is pleased to announce that a new slate of officers has been elected to lead its Board of Directors for the 2022-2024 term. The new officers are Fred Weber (Future Technology Worldwide), Chair; Trifon Liakopoulos (EnaChip Inc.), President; Renee Yawger (Efficient Power Conversion (EPC)), Vice President; and Tim McDonald (Infineon Technologies), Secretary/Treasurer.

Fred Weber expressed appreciation for Mike Hayes' leadership as Chair from 2020-2022. "The past 2 years have been difficult due to the unprecedented challenges of the pandemic and resulting impact on APEC2020 and 2021 and the many workshops sponsored and co-sponsored by the PSMA Technical Committees. Mike not only navigated these challenges but also focused the PSMA Executive Committee with a number of innovative and lasting projects." Fred looks forward to continuing this work and noted "PSMA's success relies on the active participation of our members, especially through the many Technical Committees. The Board welcomes and encourages all companies in our industry to become part of this unique industry organization."

The twelve members of the Board are elected by the member company representatives to serve three-year terms, with four members rotating off each year. The full board of directors for 2022-2023 are:

- Fred Weber, Future Technology Worldwide - Chair

- Trifon Liakopoulos, EnaChip Inc. – President

- Renee Yawger, Efficient Power Conversion (EPC) – Vice President

- Tim McDonald, Infineon Technologies – Secretary/Treasurer

- Ada Cheng, AdaClock

- Dhaval Dalal, ACP Technologies LLC

- Thomas Foulkes, Pacergy LLC

- Reenu Garg, Microchip Technology

- Ajay Hari, onsemi

- George Slama, Wurth Electronics

- Llew Vaughan-Edmunds, Navitas Semiconductor

- Brian Zahnstecher, PowerRox, LLC

As is the case in many industries, power electronics has been impacted by the Covid-19 pandemic. This includes a boost in new technologies and opportunities for power designers to capitalize on the benefits of E-learning. While it is always difficult to derive trends from large industries, as we get closer to APEC 2022, as a power engineer it is interesting to take a minute to ponder and consider what will contribute to making power supplies more efficient, more reliable and exciting to design.

Overall trends and technology

A major trend that we are all aware of is the 'electrification' and transition from fossil fuels to renewable energy. There are a lot of technological innovations required in this segment to reach the carbon neutral level expected by the European Commission, US DOE and similar initiatives in Asia. If we focus on what most of the power supplies companies are developing, I foresee that four trends, all of which will benefit from the implementation of Wide Band Gap Semiconductors, will influence the power industry in 2022:

- Reducing energy consumption

- Power supplies becoming part of the Machine-to-Machine eco-system

- Enhanced energy storage solutions

- Acceleration of harvesting energy solutions,

In the quest for reduced energy consumption, from harvesting energy to the grid, the power electronics industry is seeking new long term solutions to improve efficiency. International and local regulations have already forced power supply manufacturers to innovate, and we are seeing more stringent regulations under discussion that would require the power industry to further explore new topologies, components and materials.

One example that illustrates and will benefit from this trend is E-commerce.

E-commerce was already growing before Covid-19, but as consequence of curfews, working at home, and the drastic reduction of physical interaction, it has grown exponentially, putting a high demand on shipping hubs, computerized storage and the overall supply chain. Before we even mention the associated datacenters required to manage the E-commerce process, there are the shipping hubs and warehouses that have become gigantic and consume lots of energy. Making these hubs more energy efficient has been on the agenda for all the major players, and the 2020-2021 peak on demand was a strong a signal for the need to reconsider the way to use and to manage energy.

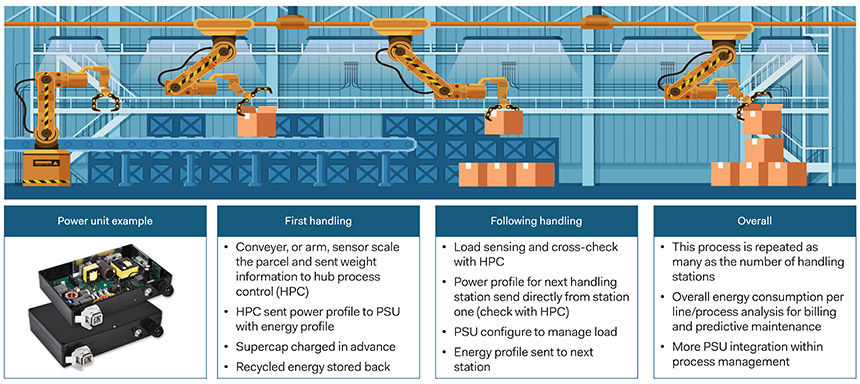

Figure 01: Smart Power operation in Smart Factory with machine-to-machine communication (Source: PRBX) Figure 01: Smart Power operation in Smart Factory with machine-to-machine communication (Source: PRBX) |

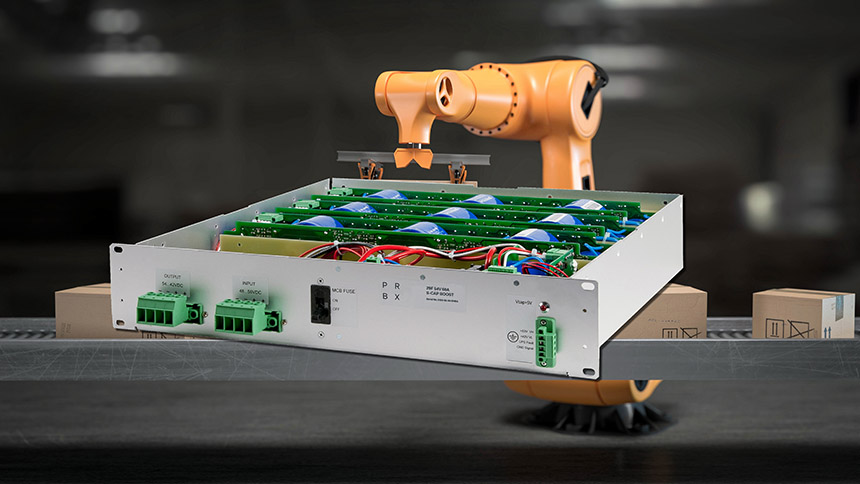

Power supplies as such are not consuming the majority of this energy, but, when one considers their strategic position in the operational chain, they become a key point in the overall process to optimize how energy is used in the complete chain. In 2022 we will see very advanced power supplies used in E-commerce handling and shipping hubs. Not only will they integrate higher levels of communication, they will also be able to store and restore energy from supercapacitors banks, reducing peak disturbances on the grid and consumption. Already experimented with in 2021, the power supplies have been integrated into a complete eco-system with Machine-to-Machine communication (Figure 01). They not only deliver power to a load e.g. conveyor motors, but they are able to sense and adjust the level of energy to store in local supercapacitors bank (Figure 02).

Figure 02 - PRBX S-CAP BOOST supercapacitors bank with digital control and communication interface able to deliver peak energy to load and to store backward energy (Source: PRBX) Figure 02 - PRBX S-CAP BOOST supercapacitors bank with digital control and communication interface able to deliver peak energy to load and to store backward energy (Source: PRBX) |

Almost invisible, from the RFID inserted in the shipping box that will get power from RF signals, to sensors placed on motors or moving elements powered by vibration, micro-systems powered by harvested energy are developing very quickly. Additionally, the nanotechnology, such as nanotubes, make it possible to develop very small supercapacitors able to store enough energy to power sensors and transmitters.

To make this possible, the implementation of digital power and communication is a must, but the level of performance will also require power electronics engineers to design new power solutions with the so called 'Wide Band Gap' semiconductors. Depending on the application and voltage required they may select GaN or SiC types, but the benefits of WBG will contribute to making E-commerce more energy efficient and to reducing the carbon footprint.

Critical building blocks!

For decades the improvements in energy efficiency levels of power supplies have been made possible by technological evolutions. Moving from linear to switching technology was an early major one, followed by a number of more minor leap-frogs until digital power came to market.

Despite it having been on the market for several years, with the emerging WBG technology and the possibilities offered by those components, digital control becomes an absolute MUST and I strongly believe it will be a major building block for power designers when developing new products.

For components, the WBG transistors are without doubt the ones that will prevail in 2022. That said, conventional Power FETs are also making big progress and power designers will have to achieve new levels of business assessment and acumen when selecting the most appropriate technology for their applications.

Figure 03 - PRBX multi-cores auto-tuned power converters with advanced digital control and GaN FET transistors (Source PRBX) Figure 03 - PRBX multi-cores auto-tuned power converters with advanced digital control and GaN FET transistors (Source PRBX) |

The third building block I foresee as important is the advanced planar transformer with interleaved multi-core technology. Not all power supplies require megahertz switching but considering the constant quest for smaller power supplies with higher efficiency, power designers will have to consider new types of transformers and new winding techniques. In that respect they will not only be helped by ferrite manufacturers developing new materials but also by Artificial Intelligence software that can shorten the time to design and test new transformer types (e.g., Frenetic, Simba).

One specific example of this is research currently being conducted at PRBX, combining digital control, GaN, and multicore transformers with advanced wiring and auto-tuned performance within the wide operational range that is seen in some industrial applications that require extremely wide input voltage ranges, as well as outputs subject to repetitive peak loads. Final products while not ready yet will not be possible without the combination of digital control, WBG and advanced magnetics (Figure 03).

I believe many of the new products that we will see in 2022 and onwards will be based on these three building blocks, which I'm sure will also include more communication to become part of a Machine-to-Machine ecosystem.

In WBG we trust!

One interesting aspect about Wide Band Gap semiconductors is that we are seeing a similar situation to when the first power MOSFETs were launched. Some immediately considered the benefits of the WBG, despite early products that were based on a depletion mode that required very specific drivers and were not very user friendly, it didn't take too long for power semiconductors manufacturers to provide 'easy-to-use' solutions.

It has now been more than five years since manufacturers first promoted the benefits of that technology but if the Go To Market is ready, the Go To Application for mass users still requires a certain amount of time.

Figure 04 - Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital (Source: PRBX) Figure 04 - Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital (Source: PRBX) |

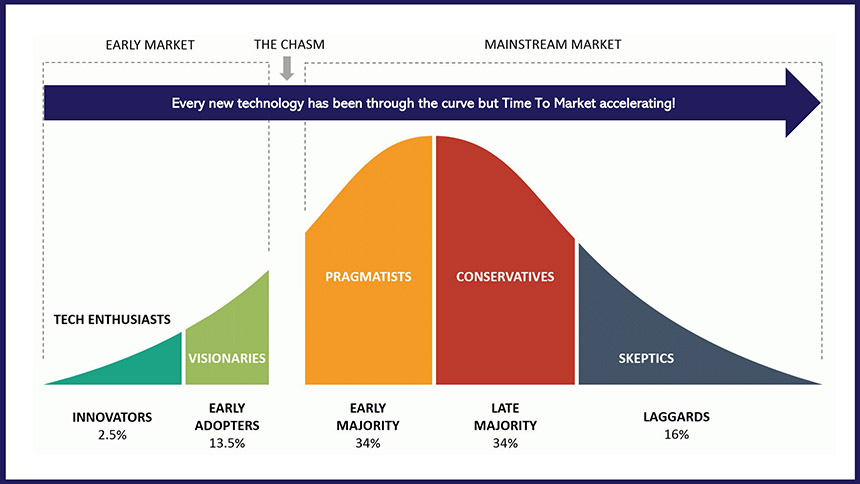

We are all familiar with the 'camel-back' curve reflecting new technology adoption and crossing the chasm. Experienced power designers have crossed that technological chasm many times, with the latest one being the migration from analog control to digital, which took more than 10 years to reach a significant level of adoption (Figure 04).

Figure 05 - Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger, contributing to reduce its size by 26% (Source PRBX/Navitas) Figure 05 - Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger, contributing to reduce its size by 26% (Source PRBX/Navitas) |

Figure 06 - Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Source: PRBX/EPC) Figure 06 - Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Source: PRBX/EPC) |

In the case of WBG, and especially Gallium Nitride (GaN), early adopters entered the fray much quicker than some had predicted a few years ago. It is no surprise that the PC and Mobile/Nomad industries were some of the early adopters. The number of USB-C chargers using GaN semiconductors announced in 2020-2021 is very impressive. Particularly worthy of mention is Navitas' next-generation GaNFast power IC that will drive the 120W ultra-fast charger supplied 'in-box' with vivo's iQOO-brand flagship iQOO 9 Pro mobile phone, demonstrating the rapid adoption of GaN by the 'nomad' industry. But it is not just the electrical performance, using GaN also reduces the physical size by 26%, reaching a stunning 1.3W/cc power density, which is quite incredible (Figure 05).

While it took 10 years for digital power to become a de facto technology, it took only five years for WBG to reach a similar level.

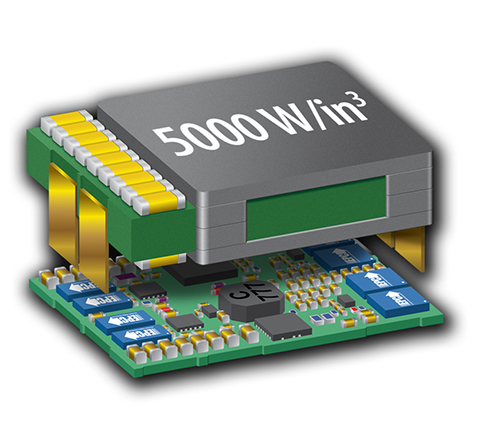

What is interesting in the development of the WBG semiconductors is that due to the specificity of this technology, with very low internal resistance and the ability to switch very fast, the packaging is very important and we see a lot of innovation from manufacturers to offer optimized solutions. Technologywise the Efficient Power Conversion (EPC) approach is very interesting, minimizing interconnection losses, and making it possible to shrink a power converter to an unprecedented size (Figure 06).

Of note is the amazing number of technical webinars held during the Covid-19 era, not to mention the virtual APEC 2021. Many companies have taken that as an opportunity for their power designers to attend online training, and as a result some power-semiconductor companies have reported shipping up to 10 times more evaluation kits than before the pandemic days.

If we simplify the market into two segments: High voltage (using SiC) and Low voltage (using GaN), we see two different patterns. High voltage applications such as electric vehicles and solar are already familiar with SiC transistors, and for that segment it is no big revolution for power engineers to undergo a learning phase for the relatively new low voltage technology.

In conclusion

In many different ways we have all been affected by the pandemic, although looking back it has contributed to a boost in learning new technology and speeding innovation. Considering all of that, 2022 will be a very important year for WBG and we can expect many new power supplies (AC/DC and DC/DC) to be announced during the year. 2022 will be a very exciting year for all of us designing power solutions.

References:

Powerbox (PRBX): https://www.prbx.com/

Navitas Semiconductors: https://navitassemi.com/

Efficient Power Conversion (EPC): https://epc-co.com/epc

Frenetic https://frenetic.ai/

SIMBA https://simba.io/

Applied Power Electronics Conferences (APEC) https://apec-conf.org/

|

Provided by Patrick Le Fèvre

|

|

Professor Cian Ó Mathúna with the 2021 EARTO Innovation Professor Cian Ó Mathúna with the 2021 EARTO InnovationAward for Impact Expected |

![]() ne of PSMA's long-time contributors and supporters, Professor Cian Ó Mathúna, from Tyndall National Institute in Cork, Ireland has been recently named the recipient of two major international awards celebrating innovative technology created in Ireland, which could have a lasting environmental impact.

ne of PSMA's long-time contributors and supporters, Professor Cian Ó Mathúna, from Tyndall National Institute in Cork, Ireland has been recently named the recipient of two major international awards celebrating innovative technology created in Ireland, which could have a lasting environmental impact.

Minimizing energy consumption in electronics continues to be a major, technological challenge. Responding to this challenge, Cian, who is currently Head of MicroNano Systems at Tyndall, has, over the last 27 years, developed MagIC (Magnetics on Silicon), an innovative technology that can greatly extend the battery life of portable electronics and dramatically reduce the energy use of high-performance electronic systems and equipment.

The ground-breaking impact of the technology has been recently recognized with prestigious awards from the 400,000 member IEEE (Institute of Electrical and Electronics Engineers) and EARTO (European Association of Research and Technology Organisations).

The IEEE Power Electronics Society Technical Achievement Award for Integration and Miniaturisation of Switching Power Converters celebrates Cian's extraordinary, global influence and leadership over the last decade in bringing together the electronics industry and academia to collaborate toward the development of the Power Supply-on-Chip (PwrSoC).

Tyndall is the first Irish recipient of an EARTO Award, which recognizes key contributions from European research to high-impact, technological innovation. The 2021 EARTO Innovation Award for Impact Expected looks to the future and recognizes the impact Professor Ó Mathúna's research will have on the technology of the future. Including dramatically reducing system energy consumption, extending battery life and reducing the overall size, weight and cost of future electronic systems.

Tyndall's MagIC technology makes bulky magnetics components in electronic equipment to disappear onto the silicon chip, just like Gordon Moore and colleagues did with the transistor over 50 years ago. Using MagIC technology, electronics will be able to use power more efficiently by minimizing the energy wasted or lost as the battery powers the multiple-voltage rails required in multi-core microprocessor chips and/or other complex SoC chips. This improved efficiency can extend the charge time of batteries by more than 50%. The breakthrough technology will have a huge impact on markets for mobile phones, IT equipment, and any device needing a battery. It is also envisaged that the technology will deliver significant energy savings in servers in the data centre and high-performance computing space.

Professor Ó Mathúna said, "This ground-breaking and disruptive innovation is set to change the global approach to how power is managed in electronic devices and will contribute to addressing a critical environmental issue for society and our planet. We continue to partner extensively with global companies to develop and commercialize the technology which has already received more than €20M in funding from research, licensing and productization. We have joint publications with companies such as Global Foundries in Dresden and Singapore; Intel, USA; Philips in the Netherlands, TI in the USA; Wurth Electronics in Germany as well as a joint patent with Apple Computers."

Cian joined the November 2021 PSMA Board of Directors meeting and was very gracious and effusive in acknowledging the influence PSMA has had on the emergence of PwrSoC over the last 3 decades. Cian mentioned that he was first introduced to PSMA by Don Staffiere who managed to convince one of his Irish clients, Gary Duffy, then MD of Computer Products (later Artseyn Technologies) to fund Cian's attendance at the 1994 APEC. Cian came to APEC with a very limited background in power electronics but, through Don's introductions to PSMA, he began participating in the PSMA Technology Roadmap initiative, and was quickly able to leverage his expertise in microelectronics packaging which was just beginning to have a very positive impact on the miniaturization and integration of power electronics products.

Joe Horzepa, Gary Duffy, Arnold Alderman and Cian Ó Mathúna at APEC in the mid 2000s Joe Horzepa, Gary Duffy, Arnold Alderman and Cian Ó Mathúna at APEC in the mid 2000s |

With the support of Don Staffiere, Bob Huljak, the late Prof. William Sarjeant and the strategic guidance and wisdom of Joe Horzepa (and Judy!), Cian engaged with Arnold Alderman and Doug Hopkins to run the Packaging Technical Committee with Brian Narveson and Ernie Parker later contributing their expertise. Around 1997/98, PSMA awarded NMRC (National Microelectronics Research Centre – the precursor to Tyndall) funding to undertake a special project on the state-of-the-art in commercial 3D power electronics packaging and followed this, in 2006/2007, with funding, for Tyndall and Anagenesis, on the very first study on fully-integrated power – the visionary and seminal "PSiP2PwrSoC" project.

Looking back, Cian sees this project as the inspiration for him to establish PwrSoC, the International Workshop on Power Supply on Chip which was first held in Cork in 2008 with over 100 international participants. At PwrSoC2010, Tyndall agreed to hand over the workshop to PSMA and the IEEE Power Electronics Society from which point the Workshop has become recognized as the flagship technical forum worldwide for both industry and academia to get together to discuss both the technological and business challenges and opportunities for PwrSoC.

In his closing remarks, Cian commented "the vision and strategic perspective of PSMA, over the last 27 years, has had a dramatic impact on seeding research in power electronics, on providing a dedicated forum to gain insight into major power industry challenges and, in particular, in providing me, and the wider team at NMRC/Tyndall, with the international perspective to succeed. For all of this, I am forever in PSMA's debt."

![]() ver the years I have worked with various safety, compliance, and certification agencies and NRTLs (Nationally Recognized Testing Laboratories) and similar types of labs. Let's call them businesses who make money from certifying products of various sorts. In the past, before legal, finance and operations ruled the world, some of these agencies were not-for-profit organizations which were funded by insurance companies to enhance safety and minimize losses from coverage of fires and damages caused by unsafe conditions in products. Today many or all the NRTLs are businesses who charge like lawyers in billable hours.

ver the years I have worked with various safety, compliance, and certification agencies and NRTLs (Nationally Recognized Testing Laboratories) and similar types of labs. Let's call them businesses who make money from certifying products of various sorts. In the past, before legal, finance and operations ruled the world, some of these agencies were not-for-profit organizations which were funded by insurance companies to enhance safety and minimize losses from coverage of fires and damages caused by unsafe conditions in products. Today many or all the NRTLs are businesses who charge like lawyers in billable hours.

This approach to safety and compliance certification has changed how test labs conduct business to the point where your success in obtaining certifications for your new product will depend to a large extent on which laboratory you choose to work with. And in my experience, your success will also depend on who you get assigned to at that particular NRTL. Success in this case involves meeting your goals for budget and time to market on your project. This article recounts a series of compliance stories, let's call them case studies, in which companies encountered difficulties in attempting to obtain safety certifications.

As these stories illustrate, there are a variety of pitfalls in the safety approvals process, often relating to the unfortunate choice of an NRTL that places profit over serving the customer. But as we'll also see, choosing the right NRTL and the right lab representative can not only avoid the nuisance problems caused by the laboratory, but also educate the customer on better design choices that will ultimately make compliance easier.

This article focuses on the problems that occur when companies seek safety compliance certifications. But before we delve into examples of these problems, let's consider some of the reasons why the choice of test lab is more of an issue with safety than with other compliance certifications.

How Safety Compliance Differs from Other Areas

First, let's define in today's landscape what compliance regulatory certifications are needed to make a product that can be sold in the marketplace. These include global environmental and materials certifications, radiated and conducted EMI-RFI, CE certification, energy efficiency standards, and electrical safety/flammability of materials. In some cases, all of these must be met. So, let's look at these areas one by one.

Environmental and materials content has turned into a mandatory disclosure area with penalties to the OEM for not conforming. While very onerous and time consuming, this process is pretty black and white. What components comprise your product inside the shipping box? And probably these days you must also disclose the contents of your shipping box, including cords and cables and perhaps even the composition of the box as well. Nevertheless, it's scientifically cut and dried.

With radiated and conducted emissions, you either meet the standard or you don't via methodology and measurements. It's pretty much a pass or fail situation and you want to pass with margin to account for production deviations.

CE is all about whether your product conforms to European health, safety, and environmental protection standards, which mostly encompasses the same items as RoHS and Reach. The CE certification is a super big deal in Europe but not a factor in the U.S. It's mostly obtained by hiring a consultant, paying them, and filling out documents in which you attest that your product adheres to the standards—tick a box and you get CE certification.

Energy efficiency standards, while they vary country by country and range from mandatory to voluntary, are also applied in scientific ways. You measure the energy consumed in various modes of operation and the product either conforms or not. If it doesn't, you re-spin the software or the hardware design until it meets the standards, and then you are certified to the standards. It's measured and validated, and again, data wins. It's a pass-fail situation. In some cases, you are allowed to self-disclose (self-certify the product).

However, what I have observed in the safety area has been very different from these other types of certifications. In my experience, it depends not only on the company you choose to certify your product, but also on who you get to work on your product certification at that agency. Without naming names of organizations, I have seen situations where one NRTL certifies a product or subsystem—and since we are in the power electronics industry lets be specific to merchant power supplies—but another NRTL rejects that certification.

The compliance process has become so challenging that some see this situation as a business opportunity. I was amazed to recently see an advertisement by a group of former NRTL test employees that will, for a fee, coach and guide you on how to get your product prepared for getting through the process at a specific, or perhaps all NRTLs. That's somewhat the reverse of a situation in the healthcare industry where insurance companies are paying retired dentists and doctors to help them reject or delay claims!

In theory, power supply makers usually will only need to get certification from one NRTL and all the other NRTLs are supposed to accept those test results. However, some labs have learned that doing so doesn't maximize billable hours. This statement is not meant to impugn all NRTLs. There are a lot of top-certificating organizations who are moral and ethical. But there are some for whom the guiding principle seems to be just "is it legal, and what can we get away with?" We'll see examples of both in the following stories.

Case 1: When NRTLs Don't Accept Each Other's Work