Powerbox, one of Europe’s largest power supply companies and a leading force for four decades in optimizing power solutions for demanding applications, has announced the release of its new ruggedized 1200W AC/DC power supply for ground based defense applications and harsh industrial environments. In metal chassis format with a baseplate for conduction cooling, the OFD1200A series can be used with a baseplate operating temperature range of -40 up to +95 degrees C. For extremely demanding applications the OFD1200A features a conformal coating and is mechanically ruggedized according to the MIL-STD810H standard. The product is as electrically well ruggedized to withstand harsh transients and meet demanding EMC performance levels as required with most common defense and the more demanding industrial applications, according to the MIL-STD- 461 CE-102 and also meeting the MIL-STD-1399-300. The power supply operates with a wide universal input range from 85 to 305VAC with power factor correction (PFC). Covering a large range of applications, its output voltage and current can be adjusted from near zero to the maximum allowed for each model. Designed for high availability, short time-to-market and to meet commercial and military off-the-shelf (COTS/MOTS) business models, the OFD1200A is available in four output voltages of 12V, 28V, 48V and 65V and can be connected in parallel up to nine units delivering an impressive total power level of up to 9,720W.

Powerbox, one of Europe’s largest power supply companies and a leading force for four decades in optimizing power solutions for demanding applications, has announced the release of its new ruggedized 1200W AC/DC power supply for ground based defense applications and harsh industrial environments. In metal chassis format with a baseplate for conduction cooling, the OFD1200A series can be used with a baseplate operating temperature range of -40 up to +95 degrees C. For extremely demanding applications the OFD1200A features a conformal coating and is mechanically ruggedized according to the MIL-STD810H standard. The product is as electrically well ruggedized to withstand harsh transients and meet demanding EMC performance levels as required with most common defense and the more demanding industrial applications, according to the MIL-STD- 461 CE-102 and also meeting the MIL-STD-1399-300. The power supply operates with a wide universal input range from 85 to 305VAC with power factor correction (PFC). Covering a large range of applications, its output voltage and current can be adjusted from near zero to the maximum allowed for each model. Designed for high availability, short time-to-market and to meet commercial and military off-the-shelf (COTS/MOTS) business models, the OFD1200A is available in four output voltages of 12V, 28V, 48V and 65V and can be connected in parallel up to nine units delivering an impressive total power level of up to 9,720W.

A number of defense applications require power supplies to operate with limited or no ventilation cooling. In this respect, those operating in harsh environments where electronic equipment is installed in a sealed box, radio communication systems subject to adverse weather conditions, outdoor surveillance and access control, and indoor equipment with very strict audible noise restrictions. In addition to environmental requirements, reliability and cost of maintenance are motivating systems designers not to use fans and blowers, privileging conduction cooling.

Conduction cooling requires very specific building practices and the PRBX OFD1200A has been designed to guarantee optimal heat transfer from the dissipating components to the baseplate, delivering a high level of performance within an operating temperature of -40 to +95 degrees centigrade at baseplate. Depending on the assembly method and the overall cooling conditions, a derating may apply as specified in the technical documentation.

To cover a large range of applications, the OFD1200A operates with a wide universal input range from 85 to 305VAC (Nominal 100 to 277VAC). The unit includes a PFC with a coefficient of 0.98/0.95 (110VAC/230VAC).

The OFD1200A is available in four versions of single output DC voltage, 12V/84A ; 28V/43A ; 48V/25A and 65V/18.5A. Using a high efficiency topology, typical efficiency for the 48V output unit at 230VAC input is an excellent 92%.

From defense to demanding industrial, the addressable range of applications requiring ruggedized power solutions is extremely large. Accordingly, Powerbox’s OFD1200A series has been designed to meet higher levels of shock and vibration, it has harsh transient protection and additional EMC filtering such as specified by MIL-STD 461E CE102, MIL-STD 1399-300A and MIL-STD 810H.

Defense applications such as battery chargers require the power supply to deliver constant current, and this must be easily adjustable. Often such equipments are operated in environments requiring the electronics to be enclosed and protected from hazards. This necessitates the power supply to offer an external control to adjust the output voltage and/or current from the maximum allowed to near zero.

To make it possible for customers to precisely adjust the voltage and current to suit their application the OFD1200A offers two analog inputs, VTRM and ITRM. Using those functions, the output voltage and current can be adjusted from near zero up to the maximum specified per model. For example, the 28V output can be adjusted from near zero volts up to 33.6V, and the output current from near zero amps up to 43A. The output voltage can also be adjusted using the provided onboard potentiometer.

The extended trimming and control function simplifies the utilization of the power supply in constant voltage (CV) or constant current (CC) mode, without adding external circuitry.

For applications requiring redundancy or higher power it is possible to connect up to nine units in parallel, delivering an impressive total power level of up to 9,720W in conduction cooling mode. To maintain the highest level of efficiency when operated in parallel or in redundancy-mode, optional active ORing circuitry deploying high performance FET technology (Option-O) is available on the OFD1200A28 and OFD1200A48.

For safety, the OFD1200A has an IN/OUT isolation of 3,000VAC and IN/FG of 2,000VAC. Output isolation to FG is 500VAC. The power supply includes over current protection with auto recovery, over voltage and over temperature protection.

The OFD1200A board includes easy access to auxiliary functions via on board connectors, namely: Remote Control, Output Voltage Sensing, Power Good, VTRM, ITRM.

The OFD1200A has passed shock and vibration testing as specified in MIL-STD-810H. In that respect the products have been tested to levels far above normal operating conditions and are designed to sustain high, 20G level shocks.

In its enclosed format, the OFD1200A measures 142 x 40 x 340mm (5.59 x 1.57 x 13.38 inches) and weighs 1.8kg max.

Benefiting from a design optimized for conduction cooling, the OFD1200A is suitable for applications requiring a silent power solution such as in a control room. Equally, it is suitable for industrial applications where forced air ventilation is not possible due to environmental constraints. Attached to a chassis or cold plate, the OFD1200A can deliver impressive power levels with a very high level of reliability.

The OFD1200A is certified in accordance with UL62368-1 3rd edition, cUL (equivalent to CAN/CSA-C22.2 No.62368-1).

The OFD1200A series has a full three-year warranty and conforms to the European RoHS, REACH and Low Voltage Directives. The product carries the CE, UKCA and cURus markings.

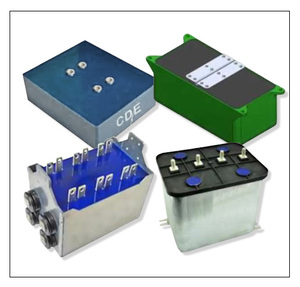

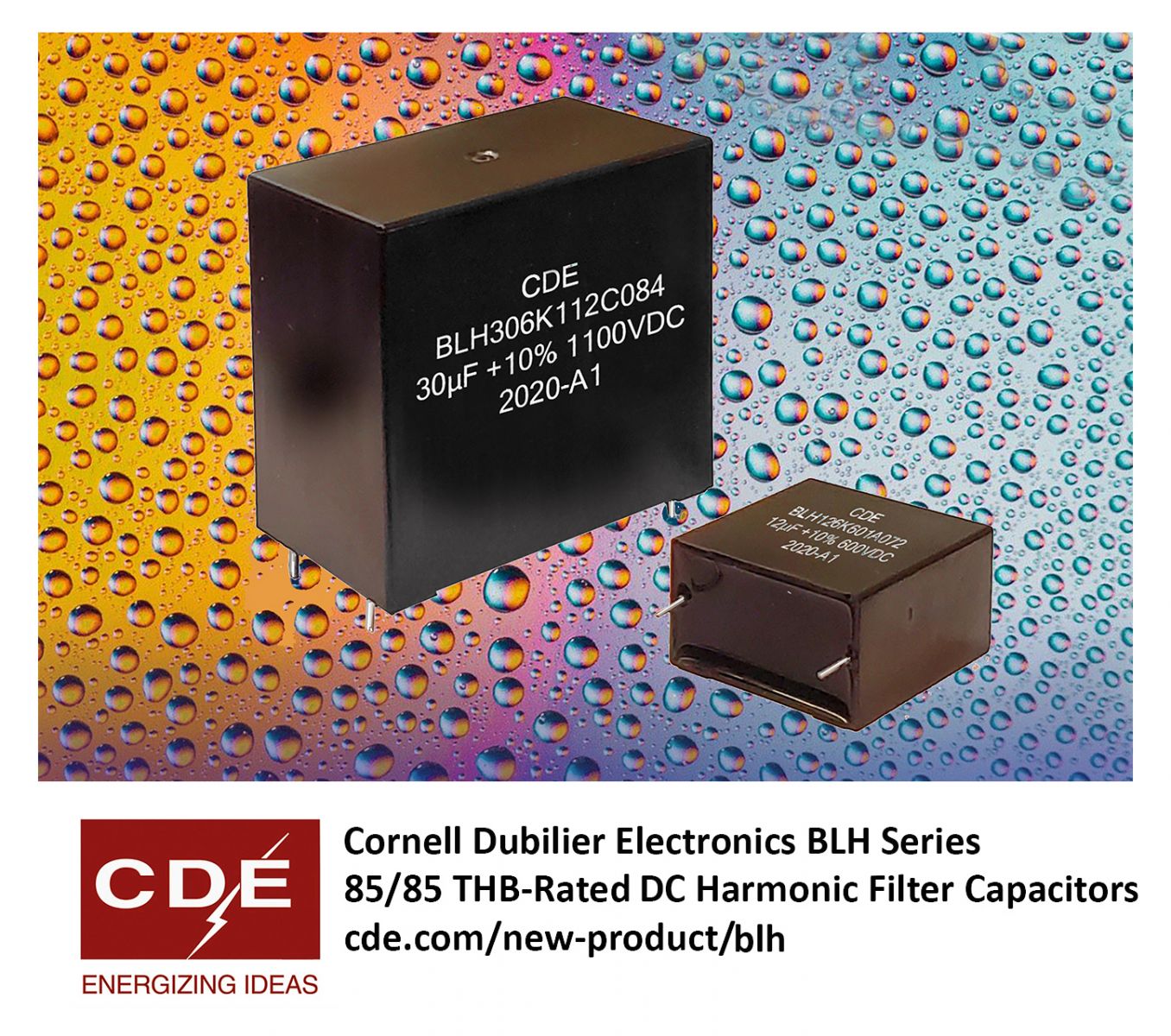

NORTHVALE, New Jersey, USA - In response to the rapidly growing demand for higher-performance DC link capacitors for EV chargers, Cornell Dubilier Electronics (CDE) has expanded its standard-product offerings with devices issued through franchise distributor New Yorker Electronics. While the inverter circuitry at the heart of EV charging stations may seem familiar to design engineers, there are operational, environmental and mechanical demands that make

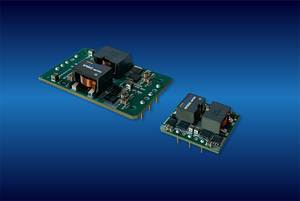

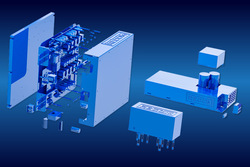

NORTHVALE, New Jersey, USA - In response to the rapidly growing demand for higher-performance DC link capacitors for EV chargers, Cornell Dubilier Electronics (CDE) has expanded its standard-product offerings with devices issued through franchise distributor New Yorker Electronics. While the inverter circuitry at the heart of EV charging stations may seem familiar to design engineers, there are operational, environmental and mechanical demands that make  Two new ranges of cost-effective switching regulators are available from RECOM - the RPMGQ-20 and RPMGS-20. Both are open-frame, through-hole, non-isolated DC/DC buck converters with an 18V-75V input. Optional nominal outputs are 5V or 12V trimmable over a wide range, 3.3V to 8V and 8V to 24V respectively. Output current for all variants is 20A and the RPMGQ-20 is in an industry-standard quarter-brick format while the RPMGS-20 is in the emerging standard package size of 36.83 x 34.04mm with a standard sixteenth brick pin-out. Both products have a maximum height of 15mm from their mounting surface.

Two new ranges of cost-effective switching regulators are available from RECOM - the RPMGQ-20 and RPMGS-20. Both are open-frame, through-hole, non-isolated DC/DC buck converters with an 18V-75V input. Optional nominal outputs are 5V or 12V trimmable over a wide range, 3.3V to 8V and 8V to 24V respectively. Output current for all variants is 20A and the RPMGQ-20 is in an industry-standard quarter-brick format while the RPMGS-20 is in the emerging standard package size of 36.83 x 34.04mm with a standard sixteenth brick pin-out. Both products have a maximum height of 15mm from their mounting surface. Greetings!

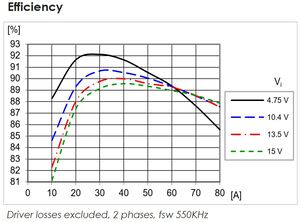

Greetings! Flex Power Modules is announcing an upgrade to the specification of their innovative BMR510, a two-phase voltage regulator module. The BMR510 now utilizes advanced materials of magnetic core, yielding high inductance in a small package size, allowing lower switching frequency operation than would be necessary with the gapped ferrite cores previously used. This in turn reduces switching losses, improving efficiency by up to a useful 1.5% to 90% compared with the original solution at 13.5 V input, 0.8 V/40 A output.

Flex Power Modules is announcing an upgrade to the specification of their innovative BMR510, a two-phase voltage regulator module. The BMR510 now utilizes advanced materials of magnetic core, yielding high inductance in a small package size, allowing lower switching frequency operation than would be necessary with the gapped ferrite cores previously used. This in turn reduces switching losses, improving efficiency by up to a useful 1.5% to 90% compared with the original solution at 13.5 V input, 0.8 V/40 A output. Greetings!

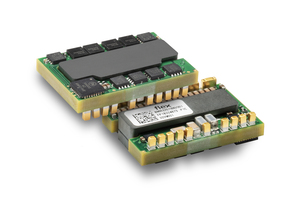

Greetings! Flex Power Modules has launched the BMR320, a non-isolated, unregulated, DC-DC intermediate bus converter with a fixed 8:1 input/output voltage ratio in a compact form-factor.

Flex Power Modules has launched the BMR320, a non-isolated, unregulated, DC-DC intermediate bus converter with a fixed 8:1 input/output voltage ratio in a compact form-factor. A new 300W-rated half-brick DC/DC converter, the REC300H-W, is now available with a wide 9V to 36VDC input and output options of 12V, 15V, 24V, and 48VDC isolated to 3kVDC/1 minute. Additionally released, our 150W-rated REC150H-UW has an ultra-wide input range of 9V to 75VDC with the same output voltage options, apart from 28V and 54VDC to suit avionic systems and PoE applications, isolated at 2.5kVDC/1 minute.

A new 300W-rated half-brick DC/DC converter, the REC300H-W, is now available with a wide 9V to 36VDC input and output options of 12V, 15V, 24V, and 48VDC isolated to 3kVDC/1 minute. Additionally released, our 150W-rated REC150H-UW has an ultra-wide input range of 9V to 75VDC with the same output voltage options, apart from 28V and 54VDC to suit avionic systems and PoE applications, isolated at 2.5kVDC/1 minute. We are proud to

We are proud to  The industry’s highest power density portfolio of stackable,

The industry’s highest power density portfolio of stackable,  Expanding our AC/DC range, the cost-effective RACM130E-K series in a 2”x4” footprint is now available with 130W peak output power from a wide 85-264Vac input.

Expanding our AC/DC range, the cost-effective RACM130E-K series in a 2”x4” footprint is now available with 130W peak output power from a wide 85-264Vac input. TI’s PCIe Gen 5.0 redriver is the pin-to-pin compatible next generation of TI’s Gen 4.0 redriver. With a PCI-SIG certified

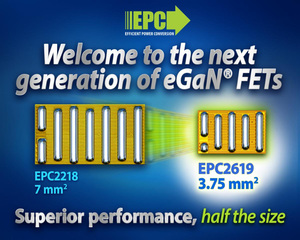

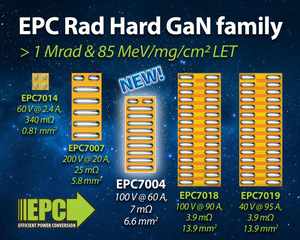

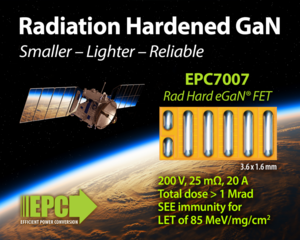

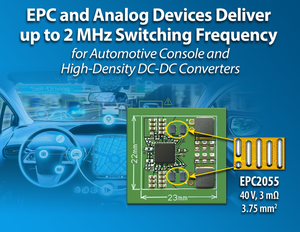

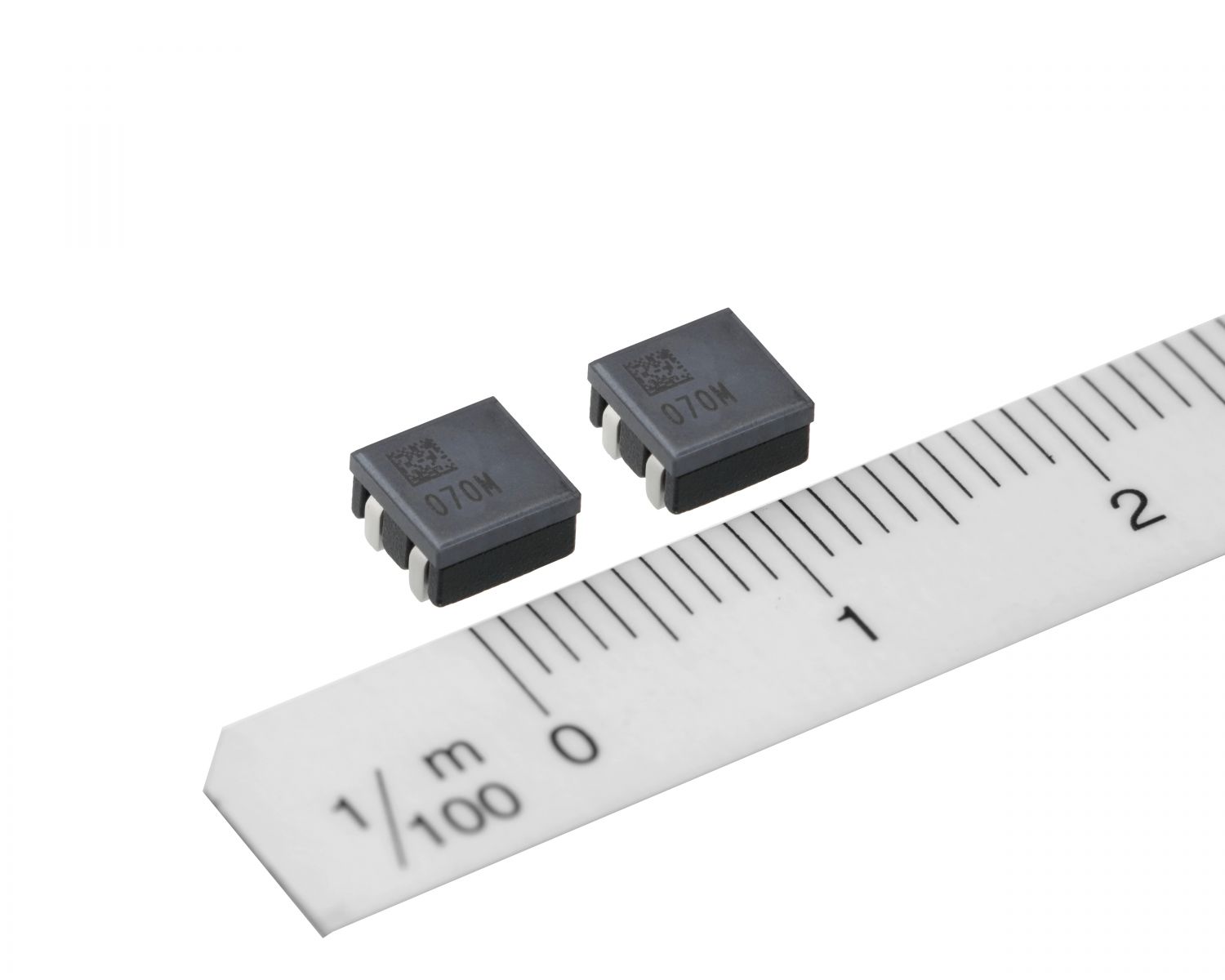

TI’s PCIe Gen 5.0 redriver is the pin-to-pin compatible next generation of TI’s Gen 4.0 redriver. With a PCI-SIG certified  EPC expands the selection of off-the-shelf GaN FETs in thermally enhanced QFN packages with the introduction of the 150 V

EPC expands the selection of off-the-shelf GaN FETs in thermally enhanced QFN packages with the introduction of the 150 V

The

The  Building on the success of our 5W board-mount RAC05-K/480 AC/DC, RECOM now offers 15W and 25W versions with the same ultra-wide input range of 85-528VAC, for line-to-line and line-to-neutral connections in global single- and three-phase AC supplies.

Building on the success of our 5W board-mount RAC05-K/480 AC/DC, RECOM now offers 15W and 25W versions with the same ultra-wide input range of 85-528VAC, for line-to-line and line-to-neutral connections in global single- and three-phase AC supplies. The RECOM RSH3 DC/DC converter is an addition to the successful RSH2 series featuring fully regulated, low-noise, and isolated 3W outputs in a surface mount package. The series features nominal inputs of 12V (9–18V) and 24V (18–36V), which are useful for battery or bus-powered systems, while the outputs available are 5V, 12V, 15V, 24V, +/−12V, and +/−15V. The parts have short-circuit and overcurrent protection, and meet EN 55032 class A or B limits for input noise with a simple external filter. No minimum load is required, and the on/off control is standard.

The RECOM RSH3 DC/DC converter is an addition to the successful RSH2 series featuring fully regulated, low-noise, and isolated 3W outputs in a surface mount package. The series features nominal inputs of 12V (9–18V) and 24V (18–36V), which are useful for battery or bus-powered systems, while the outputs available are 5V, 12V, 15V, 24V, +/−12V, and +/−15V. The parts have short-circuit and overcurrent protection, and meet EN 55032 class A or B limits for input noise with a simple external filter. No minimum load is required, and the on/off control is standard. EPC expands the selection of off-the-shelf GaN FETs in thermally enhanced QFN packages with the introduction of the 100 V

EPC expands the selection of off-the-shelf GaN FETs in thermally enhanced QFN packages with the introduction of the 100 V  The newly expanded

The newly expanded  We are proud to

We are proud to  We are excited to announce the release of a new range of DC/DC converters for E-mobility applications. With the push for zero-emission transport, electric propulsion is the ideal solution for off-highway vehicles and they invariably require DC/DC converters to generate isolated auxiliary power rails from the traction battery. The compact and cost-effective RMOD500-W range introduced is perfect for the application as the products are IP67-rated, fully sealed against moisture and dust including connectors and can therefore be fitted in any unprotected area of the vehicle.

We are excited to announce the release of a new range of DC/DC converters for E-mobility applications. With the push for zero-emission transport, electric propulsion is the ideal solution for off-highway vehicles and they invariably require DC/DC converters to generate isolated auxiliary power rails from the traction battery. The compact and cost-effective RMOD500-W range introduced is perfect for the application as the products are IP67-rated, fully sealed against moisture and dust including connectors and can therefore be fitted in any unprotected area of the vehicle. With improved charging speed, 800 V batteries are becoming standard for electric vehicles. PI’s AEC-Q100 qualified

With improved charging speed, 800 V batteries are becoming standard for electric vehicles. PI’s AEC-Q100 qualified  A new design example report (

A new design example report ( The

The  With a nanocrystalline metal core, SCF-XV achieves higher inductance and impedance values, a broader frequency response, and a smaller footprint than other common mode chokes currently available.

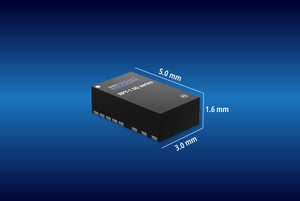

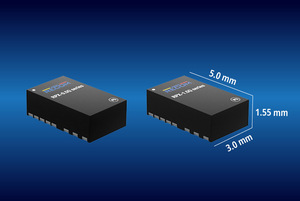

With a nanocrystalline metal core, SCF-XV achieves higher inductance and impedance values, a broader frequency response, and a smaller footprint than other common mode chokes currently available. RECOM has added further automotive-qualified parts to its product range with the RPY-1.5Q: a high-efficiency, cost-effective, 1.5A-rated LED driver. Meeting the requirements of AEC-Q100 with optional ‘wettable flanks’ for Automated Optical Inspection, the product comes in a thermally-enhanced QFN package with integrated shielded inductor and is just 3 x 5 x 1.6mm. The RPY-1.5Q operates over an input range of 4 to 36VDC, covering nominal 5, 12, or 24V. The part can be adjusted for lower constant currents, and PWM or analog 0-100% dimming is possible. Temperature rating is -40°C to +125°C junction temperature, and the part features an enable input and fault flag indicator. Full protection is included against input undervoltage, over-temperature, and output short circuit and over-current.

RECOM has added further automotive-qualified parts to its product range with the RPY-1.5Q: a high-efficiency, cost-effective, 1.5A-rated LED driver. Meeting the requirements of AEC-Q100 with optional ‘wettable flanks’ for Automated Optical Inspection, the product comes in a thermally-enhanced QFN package with integrated shielded inductor and is just 3 x 5 x 1.6mm. The RPY-1.5Q operates over an input range of 4 to 36VDC, covering nominal 5, 12, or 24V. The part can be adjusted for lower constant currents, and PWM or analog 0-100% dimming is possible. Temperature rating is -40°C to +125°C junction temperature, and the part features an enable input and fault flag indicator. Full protection is included against input undervoltage, over-temperature, and output short circuit and over-current. With the industry's widest-bandwidth, fully differential RF amplifier, the

With the industry's widest-bandwidth, fully differential RF amplifier, the  The

The  The successful RECOM RPX QFN-packaged DC/DC converters now have ‘-Q’ variants which meet stringent automotive AEC-Q100 Grade 1 requirements and have been upgraded to include ‘wettable flanks’ for Automated Optical Inspection (AOI). The DC/DCs have an input range up to 36V, and the output can be trimmed from 0.8V to 30V. The RPX-0.5Q variant delivers 0.5A, and the RPX-1.5Q delivers 1.5A, both in a tiny 3 x 5 x 1.6mm leadless, thermally-enhanced QFN package, operating to well over 100°C ambient with derating. This is enabled by state-of-the-art integration and advanced 3D packaging techniques using an over-molded Flip Chip on Leadframe (FCOL) construction to provide lowest package thermal resistance while keeping manufacturing and end-product pricing low.

The successful RECOM RPX QFN-packaged DC/DC converters now have ‘-Q’ variants which meet stringent automotive AEC-Q100 Grade 1 requirements and have been upgraded to include ‘wettable flanks’ for Automated Optical Inspection (AOI). The DC/DCs have an input range up to 36V, and the output can be trimmed from 0.8V to 30V. The RPX-0.5Q variant delivers 0.5A, and the RPX-1.5Q delivers 1.5A, both in a tiny 3 x 5 x 1.6mm leadless, thermally-enhanced QFN package, operating to well over 100°C ambient with derating. This is enabled by state-of-the-art integration and advanced 3D packaging techniques using an over-molded Flip Chip on Leadframe (FCOL) construction to provide lowest package thermal resistance while keeping manufacturing and end-product pricing low. Power Integrations’ new

Power Integrations’ new  OEMs are experiencing increasing application complexity and the need for AUTOSAR, ISO 26262 functional safety-compliant and secure solutions as the market for electric and autonomous vehicles grows. For automotive developers looking to design scalable applications for future technology while also meeting the latest automotive requirements, Microchip Technology Inc. (Nasdaq: MCHP) today announces a comprehensive ecosystem around

OEMs are experiencing increasing application complexity and the need for AUTOSAR, ISO 26262 functional safety-compliant and secure solutions as the market for electric and autonomous vehicles grows. For automotive developers looking to design scalable applications for future technology while also meeting the latest automotive requirements, Microchip Technology Inc. (Nasdaq: MCHP) today announces a comprehensive ecosystem around  The

The  The TPS7A94 offers at least

The TPS7A94 offers at least  The

The  The

The  AM263

AM263  We are pleased to introduce the

We are pleased to introduce the  Cornell Dubilier Electronics, Inc. announced that it has expanded its signature series of 380LX and 381LX aluminum electrolytic capacitors to include voltages up to 600 Vdc. The new ratings are designed to serve the company’s industrial electronics customers who continue to push the application boundaries for these components into higher voltages.

Cornell Dubilier Electronics, Inc. announced that it has expanded its signature series of 380LX and 381LX aluminum electrolytic capacitors to include voltages up to 600 Vdc. The new ratings are designed to serve the company’s industrial electronics customers who continue to push the application boundaries for these components into higher voltages. We are extremely pleased to announce the production release of the

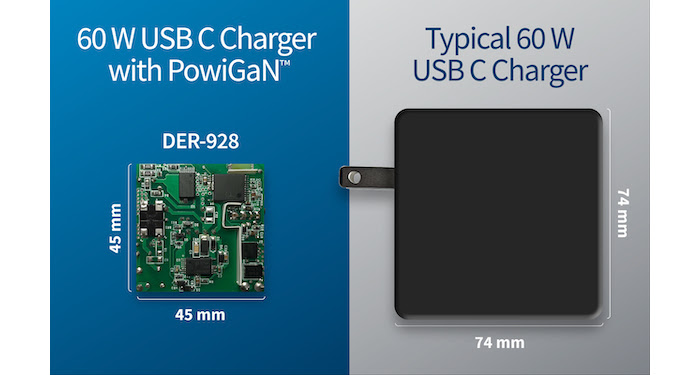

We are extremely pleased to announce the production release of the  As USB Type-C becomes the dominant charging interface for electronic devices, design engineers face the challenge of fitting increasingly high-power USB Type-C ports into wall receptacles with limited space and ability to dissipate the extra heat they generate. We’ve got a solution for that.

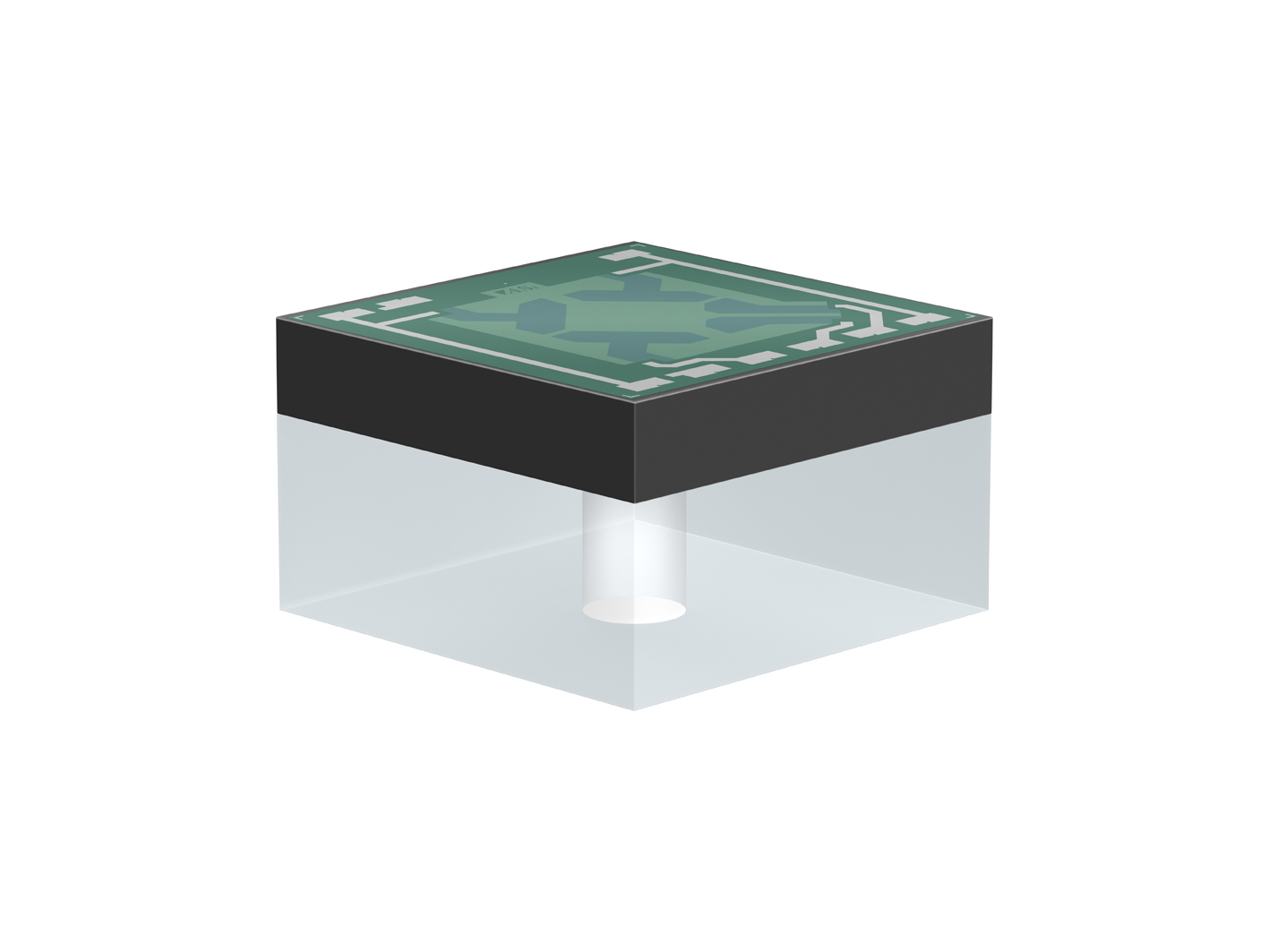

As USB Type-C becomes the dominant charging interface for electronic devices, design engineers face the challenge of fitting increasingly high-power USB Type-C ports into wall receptacles with limited space and ability to dissipate the extra heat they generate. We’ve got a solution for that. TDK Corporation announces the availability of FS1412 microPOL (μPOL™) power module. At 5.8. mm x 4.9 mm x 1.6 mm, the FS1412 is part of a new series of µPOL™ DC-DC converters with increased performance, smallest available size, ease of use, and simplified integration for applications such as big data, machine learning, artificial intelligence (AI), 5G cells, IoT networking, telecommunication, and computing enterprise. μPOL technology includes a DC-DC converter placed in the vicinity of complex chipsets such as ASICs, FPGAs, and others. By minimizing the distance between the converter and the chipset, the resistance and the inductance components are minimized, allowing fast response and accurate regulation with dynamic load currents. Mass production of FS1412 started in Q4 2021.

TDK Corporation announces the availability of FS1412 microPOL (μPOL™) power module. At 5.8. mm x 4.9 mm x 1.6 mm, the FS1412 is part of a new series of µPOL™ DC-DC converters with increased performance, smallest available size, ease of use, and simplified integration for applications such as big data, machine learning, artificial intelligence (AI), 5G cells, IoT networking, telecommunication, and computing enterprise. μPOL technology includes a DC-DC converter placed in the vicinity of complex chipsets such as ASICs, FPGAs, and others. By minimizing the distance between the converter and the chipset, the resistance and the inductance components are minimized, allowing fast response and accurate regulation with dynamic load currents. Mass production of FS1412 started in Q4 2021. This week our versatile

This week our versatile  TDK Corporation has expanded its tried-and-tested range of CeraLink capacitors. Previously, only large, ready-to-fit sizes were available. Now, smaller versions with the classic chip design are included in the portfolio in order to increase the areas of application. The new portfolio starts with the EIA 2220 size, measuring 5.7 x 5 x 1.4 mm, is intended for 500 V, and offers a capacitance of 250 nF with very low parasitic coefficients. The new capacitors with the ordering code B58043* are available with both standard and soft termination. TDK will add further designs and voltage classes in the future.

TDK Corporation has expanded its tried-and-tested range of CeraLink capacitors. Previously, only large, ready-to-fit sizes were available. Now, smaller versions with the classic chip design are included in the portfolio in order to increase the areas of application. The new portfolio starts with the EIA 2220 size, measuring 5.7 x 5 x 1.4 mm, is intended for 500 V, and offers a capacitance of 250 nF with very low parasitic coefficients. The new capacitors with the ordering code B58043* are available with both standard and soft termination. TDK will add further designs and voltage classes in the future. The TI DLP® LightCrafter™ Display 230NP EVM is an easy to use, plug-and-play evaluation platform for a wide array of ultra-mobile and ultra-portable display applications in consumer, industrial, medical and Internet of Things (IoT) markets, and is compatible with Raspberry Pi. The evaluation module (EVM) features the DLP230NP chipset comprised of the

The TI DLP® LightCrafter™ Display 230NP EVM is an easy to use, plug-and-play evaluation platform for a wide array of ultra-mobile and ultra-portable display applications in consumer, industrial, medical and Internet of Things (IoT) markets, and is compatible with Raspberry Pi. The evaluation module (EVM) features the DLP230NP chipset comprised of the  RECOM has announced the launch of their RAC10E-K/277 series of board-mount AC/DC encapsulated modules, rated at 10W in a compact 1.8 x 1 inch (45.7 x 25.4mm) footprint. Part of the RECOM ‘Economy’ series, the modules are available with single 3.3, 5, 12, 15 and 24V fully regulated outputs and with a wide input range that includes nominal 100, 115, 240 and 277VAC (120 – 430VDC). The parts are particularly suitable for harsh electrical environments such as in EV chargers with their Over Voltage Category OVC III rating up to 2000m and wide operating temperature of -40 to +90°C. The parts will also find applications in industrial, AV and ITE environments, with their safety certifications to IEC/EN/UL/CSA 62368-1 and compliance with OVC II up to 5000m. ‘Class B’ EMC limits are also met without external components and the parts are ErP-compliant with no-load losses of less than 100mW.

RECOM has announced the launch of their RAC10E-K/277 series of board-mount AC/DC encapsulated modules, rated at 10W in a compact 1.8 x 1 inch (45.7 x 25.4mm) footprint. Part of the RECOM ‘Economy’ series, the modules are available with single 3.3, 5, 12, 15 and 24V fully regulated outputs and with a wide input range that includes nominal 100, 115, 240 and 277VAC (120 – 430VDC). The parts are particularly suitable for harsh electrical environments such as in EV chargers with their Over Voltage Category OVC III rating up to 2000m and wide operating temperature of -40 to +90°C. The parts will also find applications in industrial, AV and ITE environments, with their safety certifications to IEC/EN/UL/CSA 62368-1 and compliance with OVC II up to 5000m. ‘Class B’ EMC limits are also met without external components and the parts are ErP-compliant with no-load losses of less than 100mW. TDK Corporation announces the release of its newly developed AVRF041A150MT242 and AVRF061D2R4ST532 notch filters with ESD protection function. Volume production of these devices will begin in March 2022.

TDK Corporation announces the release of its newly developed AVRF041A150MT242 and AVRF061D2R4ST532 notch filters with ESD protection function. Volume production of these devices will begin in March 2022.

TDK Corporation introduces the new PCM120T series of shielded SMT power inductors, optimized for high saturation currents and low DC resistances. The PCM120T product family includes 14 inductance values between 0.4 µH and 10 µH, whereby saturation currents of up to 80 A are reached depending on the L value. Optimal saturation properties are achieved through the use of an iron alloy core. Flat wire windings are used to keep losses as low as possible. This results in low ohmic resistance values (RDC) of 0.72 mΩ (0.4 µH) to 9 mΩ (10 µH). The new inductors have an outstanding EMC performance due to closed housing made of ferrite material without an external gap. They are ideal for automatic solder joint inspection (AOI) and achieve a coplanarity of <0.1 mm due to their lead frame structure. The product’s metal cores provide resistance against high voltage pulses in accordance with ISO7636. The components’ dimensions are 12.7 x 15.8 x 11.5 mm (W x L x H).. The powerful RoHS-compatible inductors are designed for a wide temperature range from -55 °C to +165 °C and are certified according to AEC-Q200.

TDK Corporation introduces the new PCM120T series of shielded SMT power inductors, optimized for high saturation currents and low DC resistances. The PCM120T product family includes 14 inductance values between 0.4 µH and 10 µH, whereby saturation currents of up to 80 A are reached depending on the L value. Optimal saturation properties are achieved through the use of an iron alloy core. Flat wire windings are used to keep losses as low as possible. This results in low ohmic resistance values (RDC) of 0.72 mΩ (0.4 µH) to 9 mΩ (10 µH). The new inductors have an outstanding EMC performance due to closed housing made of ferrite material without an external gap. They are ideal for automatic solder joint inspection (AOI) and achieve a coplanarity of <0.1 mm due to their lead frame structure. The product’s metal cores provide resistance against high voltage pulses in accordance with ISO7636. The components’ dimensions are 12.7 x 15.8 x 11.5 mm (W x L x H).. The powerful RoHS-compatible inductors are designed for a wide temperature range from -55 °C to +165 °C and are certified according to AEC-Q200. TDK Corporation expands its product lineup with a new chip varistor, type AVRH10C101KT4R7YA8, for automotive application Ethernet with strong resistance to ESD. Mass production will begin in March 2022.

TDK Corporation expands its product lineup with a new chip varistor, type AVRH10C101KT4R7YA8, for automotive application Ethernet with strong resistance to ESD. Mass production will begin in March 2022. RECOM offers fully custom, semi-custom and modified-standard AC/DC and DC/DC converters from low power up to kilowatts.

RECOM offers fully custom, semi-custom and modified-standard AC/DC and DC/DC converters from low power up to kilowatts. RECOM has added a 20W part to its ‘E-K’ range of encapsulated, PCB-mount AC/DC modules, the RAC20E-K/277. Even though it is economical designed the series is dimensionally of the same size as the existing 20W at just 52.7mm x 27.6mm footprint, but with a different pinning it is compatible with a further industry standards. It also features full load operation over a very wide input range of 85 – 305Vac. Single outputs of 5V, 12V or 24V are available, all at 80%+ efficiency, and no-load power consumption is less than 200mW to meet ECO directives. The ‘E-K’ range from RECOM is dimensionally the same as their ‘K’ series but with different pinning for compatibility with a wide range of industry standards.

RECOM has added a 20W part to its ‘E-K’ range of encapsulated, PCB-mount AC/DC modules, the RAC20E-K/277. Even though it is economical designed the series is dimensionally of the same size as the existing 20W at just 52.7mm x 27.6mm footprint, but with a different pinning it is compatible with a further industry standards. It also features full load operation over a very wide input range of 85 – 305Vac. Single outputs of 5V, 12V or 24V are available, all at 80%+ efficiency, and no-load power consumption is less than 200mW to meet ECO directives. The ‘E-K’ range from RECOM is dimensionally the same as their ‘K’ series but with different pinning for compatibility with a wide range of industry standards. A new member of PI’s acclaimed

A new member of PI’s acclaimed  The

The  TDK Corporation announces the introduction of 12V and 48V output models to the conduction cooled TDK-Lambda brand PFH500F series of AC-DC power modules. The power supplies are rated at 504W, feature a compact 4” x 2.4” footprint with programming and communication through a PMBus™ interface. These power supplies are ideal for a variety of applications including COTS (Commercial-Off-The-Shelf) applications, power amplifiers, LED displays and test equipment.

TDK Corporation announces the introduction of 12V and 48V output models to the conduction cooled TDK-Lambda brand PFH500F series of AC-DC power modules. The power supplies are rated at 504W, feature a compact 4” x 2.4” footprint with programming and communication through a PMBus™ interface. These power supplies are ideal for a variety of applications including COTS (Commercial-Off-The-Shelf) applications, power amplifiers, LED displays and test equipment. Add new functionality to your satellite designs while keeping power supplies small. The

Add new functionality to your satellite designs while keeping power supplies small. The  PowiGaN Technology

PowiGaN Technology The

The  The latest addition to RECOM’s railway portfolio is the RMD500-EW series. Featuring 500W rating with a wide 4:1 (43-154VDC) input range (170V peak) and 24V output, the product is suitable for nominal 72V and 110VDC inputs with tolerance and surges according to EN 50155. The RMD500-EW is designed for ‘plug and play’ use with all features required by EN 50155 included: reverse polarity protection, EMC and surge filtering, inrush current limiting and 10ms hold-up time. All relevant rail environmental standards are met for conducted and radiated EMI, mechanical shock and vibration, thermal shock, temperature cycling and fire protection.

The latest addition to RECOM’s railway portfolio is the RMD500-EW series. Featuring 500W rating with a wide 4:1 (43-154VDC) input range (170V peak) and 24V output, the product is suitable for nominal 72V and 110VDC inputs with tolerance and surges according to EN 50155. The RMD500-EW is designed for ‘plug and play’ use with all features required by EN 50155 included: reverse polarity protection, EMC and surge filtering, inrush current limiting and 10ms hold-up time. All relevant rail environmental standards are met for conducted and radiated EMI, mechanical shock and vibration, thermal shock, temperature cycling and fire protection. Meet our new 3-GHz high-input-impedance buffer, the

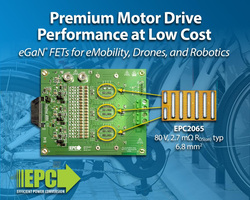

Meet our new 3-GHz high-input-impedance buffer, the  A new 2 kW, two-phase 48 V – 14 V bidirectional converter that operates with 96.8% peak efficiency in a small footprint. The board features the ePower™ 100 V, 65 A integrated circuit chipset. The chipset includes the

A new 2 kW, two-phase 48 V – 14 V bidirectional converter that operates with 96.8% peak efficiency in a small footprint. The board features the ePower™ 100 V, 65 A integrated circuit chipset. The chipset includes the  RECOM has extended its range of AC/DC open-frame power supplies with the RACM600-L series. The module can deliver 400/450W (115/230VAC) with convection cooling while 600W is available with continuously forced airflow. The product features a universal 80-275VAC input and a single 24V output, adjustable +/-20%, rated at 25A. A standby output at 5V/0.5A is also available.

RECOM has extended its range of AC/DC open-frame power supplies with the RACM600-L series. The module can deliver 400/450W (115/230VAC) with convection cooling while 600W is available with continuously forced airflow. The product features a universal 80-275VAC input and a single 24V output, adjustable +/-20%, rated at 25A. A standby output at 5V/0.5A is also available. A new 2 kW, two-phase 48 V – 14 V bidirectional converter that operates with 96.8% peak efficiency in a small footprint. The board features the ePower™ 100 V, 65 A integrated circuit chipset. The chipset includes the

A new 2 kW, two-phase 48 V – 14 V bidirectional converter that operates with 96.8% peak efficiency in a small footprint. The board features the ePower™ 100 V, 65 A integrated circuit chipset. The chipset includes the

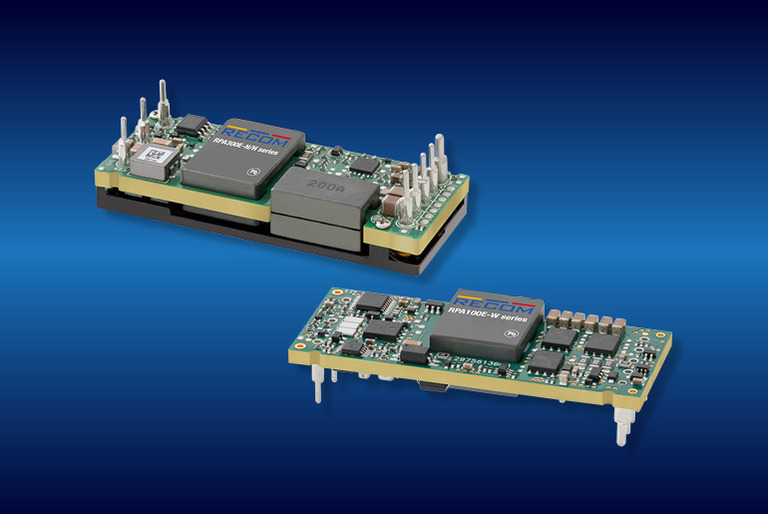

The RPA300E 300W part has an input range of 36-75V for nominal 48V supplies and features an output trimmable over a wide range of 16-35V. Isolation of this part is 2.25kVDC/1 min, basic grade. The RPA300E has an integrated heat spreader that allows direct screw-fixing to a heatsink or cold wall. Full-load operation of this part without heatsinking is to 60°C with forced air and to 85°C with load derating.

The RPA300E 300W part has an input range of 36-75V for nominal 48V supplies and features an output trimmable over a wide range of 16-35V. Isolation of this part is 2.25kVDC/1 min, basic grade. The RPA300E has an integrated heat spreader that allows direct screw-fixing to a heatsink or cold wall. Full-load operation of this part without heatsinking is to 60°C with forced air and to 85°C with load derating. A new Bluetooth Low Energy (BLE) smart dimmer wall switch design showcases the unmatched level of integration realized by the

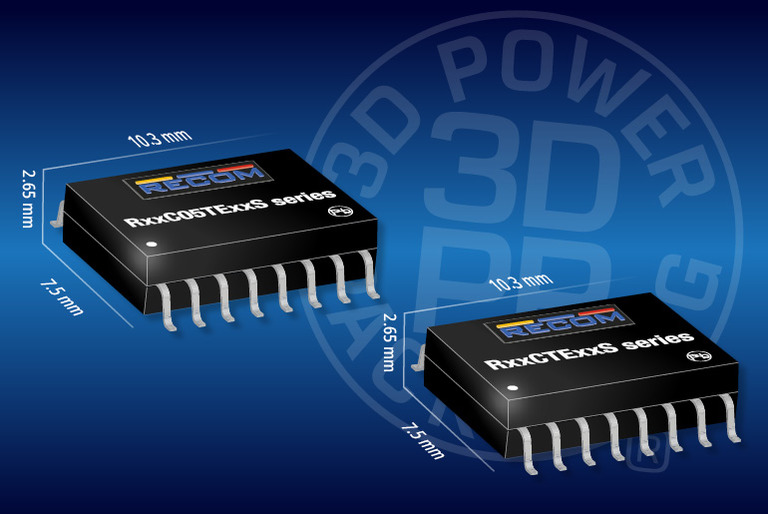

A new Bluetooth Low Energy (BLE) smart dimmer wall switch design showcases the unmatched level of integration realized by the  RECOM has extended its range of DC/DC converters in a SOIC-16 package with new versions which offer even better value. The parts feature 5V (4.5-5.5V) inputs and a semi-regulated 5V output rated at either 0.5W (R05C05TE05S) or 1W (R05CTE05S). Line and load regulation figures are specified across the full temperature range, and there is no minimum load requirement, making the parts ideal for applications that have light-load operation modes.

RECOM has extended its range of DC/DC converters in a SOIC-16 package with new versions which offer even better value. The parts feature 5V (4.5-5.5V) inputs and a semi-regulated 5V output rated at either 0.5W (R05C05TE05S) or 1W (R05CTE05S). Line and load regulation figures are specified across the full temperature range, and there is no minimum load requirement, making the parts ideal for applications that have light-load operation modes. TDK Corporation presents the new C35 type pressure sensor element, designed to measure a range of 0 to 100 mbar. It combines high sensitivity with extremely low dimensions of just 2.05 x 2.05 x 1.2 mm, enabling compact pressure sensor designs.

TDK Corporation presents the new C35 type pressure sensor element, designed to measure a range of 0 to 100 mbar. It combines high sensitivity with extremely low dimensions of just 2.05 x 2.05 x 1.2 mm, enabling compact pressure sensor designs..png) Since the 2019 release of the 3rd edition textbook,

Since the 2019 release of the 3rd edition textbook,

MinDCet

MinDCet Flex Power Modules has added 30 W dual output variants to its PKE range of through-hole, encapsulated, board-mounted DC/DC converters. The PKE532x series has an 18-75 Vdc (100 V peak) input range suitable for 24, 28 or 48 V nominals and the PKE332x series input range is 9-36 Vdc (50 V peak). Both parts are available with either +/-12V or +/15 V fully regulated dual outputs, with power ratings of 30 W total.

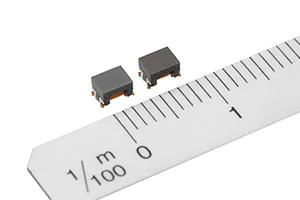

Flex Power Modules has added 30 W dual output variants to its PKE range of through-hole, encapsulated, board-mounted DC/DC converters. The PKE532x series has an 18-75 Vdc (100 V peak) input range suitable for 24, 28 or 48 V nominals and the PKE332x series input range is 9-36 Vdc (50 V peak). Both parts are available with either +/-12V or +/15 V fully regulated dual outputs, with power ratings of 30 W total. TDK Corporation (TSE:6762) announces the release of its newly developed ADL3225VM inductors for use in automotive Power over Coax (PoC) systems. Measuring at 3.2 x 2.5 x 2.5 mm (L xW x H), these inductors provide a compact solution for designers looking to reduce vehicle weight as manufacturers add more sensors and cameras to accommodate expanding automotive and advanced driver-assistance systems (ADAS) applications. The proprietary structural design and wire winding manufacturing process ensure high impedance over a broad bandpass of 1 MHz up to 1 GHz. The inductors are compliant with AEC-Q200 and achieve the highest-rated current in the industry for the 3225 size*. Volume production began in October 2021.

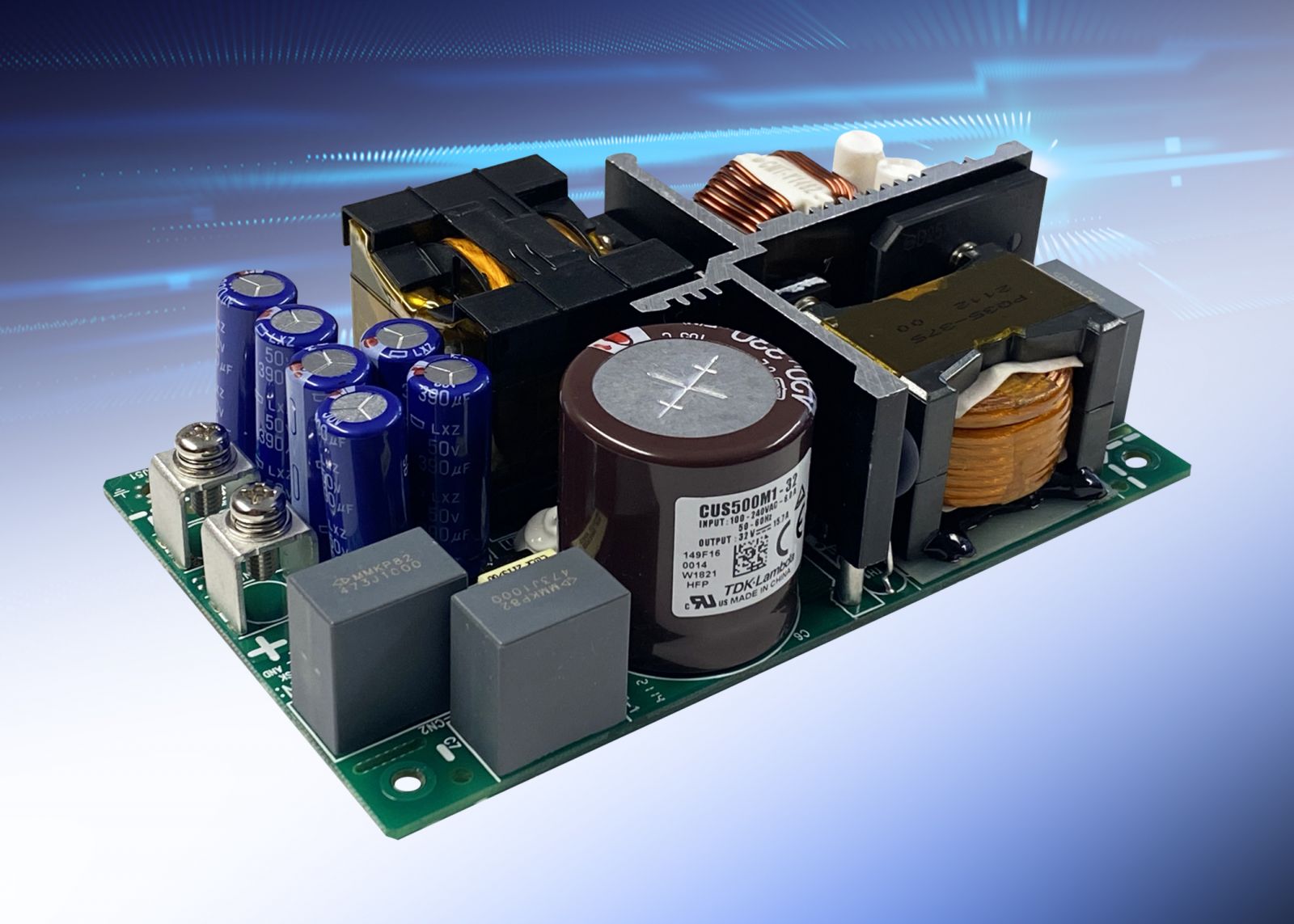

TDK Corporation (TSE:6762) announces the release of its newly developed ADL3225VM inductors for use in automotive Power over Coax (PoC) systems. Measuring at 3.2 x 2.5 x 2.5 mm (L xW x H), these inductors provide a compact solution for designers looking to reduce vehicle weight as manufacturers add more sensors and cameras to accommodate expanding automotive and advanced driver-assistance systems (ADAS) applications. The proprietary structural design and wire winding manufacturing process ensure high impedance over a broad bandpass of 1 MHz up to 1 GHz. The inductors are compliant with AEC-Q200 and achieve the highest-rated current in the industry for the 3225 size*. Volume production began in October 2021. TDK Corporation announces the introduction of the TDK-Lambda brand CUS500M1 AC-DC power supplies. The series is rated at 500W and is packaged in a 3 x 5” footprint. It provides an alternative for the 600W CUS600M models and an easy cost reduction for lower power, more cost sensitive applications. The CUS500M1 is suitable for use in a wide range of Class I or Class II (double insulated) applications, including home healthcare, medical, dental, test and measurement, broadcast and industrial equipment.

TDK Corporation announces the introduction of the TDK-Lambda brand CUS500M1 AC-DC power supplies. The series is rated at 500W and is packaged in a 3 x 5” footprint. It provides an alternative for the 600W CUS600M models and an easy cost reduction for lower power, more cost sensitive applications. The CUS500M1 is suitable for use in a wide range of Class I or Class II (double insulated) applications, including home healthcare, medical, dental, test and measurement, broadcast and industrial equipment..jpg) KEMET, part of the YAGEO Group and leading global electronic components supplier, announces its new R53 series of miniature, polypropylene film X2 EMI (electromagnetic interference) suppression capacitors. This series fulfills the growing need for automotive, industrial, consumer, and energy applications that require a smaller, high-capacitance X2 class solution for suppressing EMI. The R53 series offers capacitance values from 0.1µF to 22µF, lead-spacing from 15mm to 37.5mmm, 85/85 THB Class IIIB classification, and long-life stability in harsh environmental conditions. Its volume, on average, is 60% smaller than competitive X2 class capacitors, enabling a smaller PCB area, reduced weight, lower costs and improved reliability. These features position R53 as an exceptional X2 class solution that addresses design engineers' size, capacitance, and reliability challenges across multiple industries.

KEMET, part of the YAGEO Group and leading global electronic components supplier, announces its new R53 series of miniature, polypropylene film X2 EMI (electromagnetic interference) suppression capacitors. This series fulfills the growing need for automotive, industrial, consumer, and energy applications that require a smaller, high-capacitance X2 class solution for suppressing EMI. The R53 series offers capacitance values from 0.1µF to 22µF, lead-spacing from 15mm to 37.5mmm, 85/85 THB Class IIIB classification, and long-life stability in harsh environmental conditions. Its volume, on average, is 60% smaller than competitive X2 class capacitors, enabling a smaller PCB area, reduced weight, lower costs and improved reliability. These features position R53 as an exceptional X2 class solution that addresses design engineers' size, capacitance, and reliability challenges across multiple industries. Power Integrations

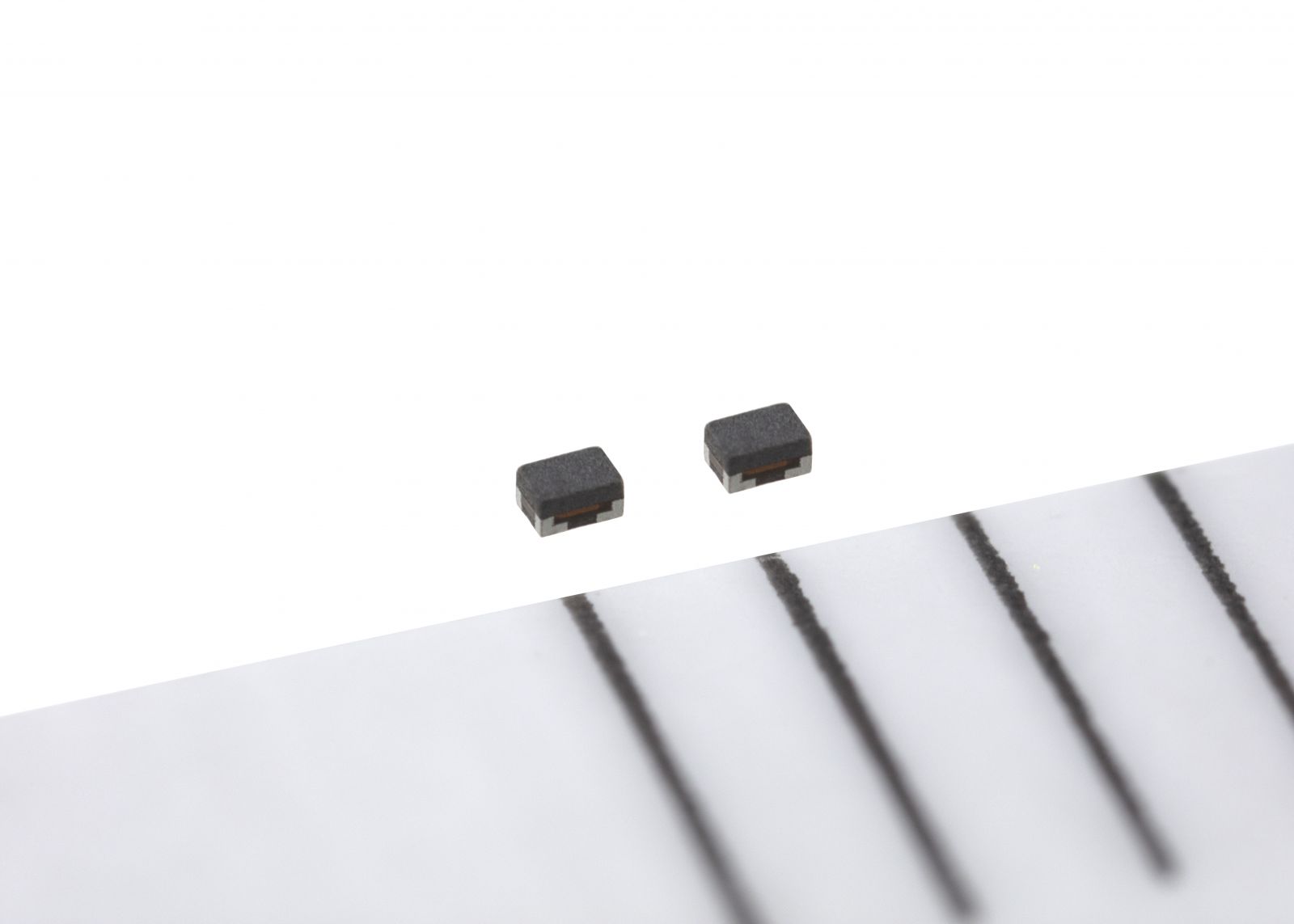

Power Integrations Hybrid Type Power Inductor: NR Series M-Type

Hybrid Type Power Inductor: NR Series M-Type Power Integrations (Nasdaq:

Power Integrations (Nasdaq:  TDK Corporation today announced the development and mass production of the MMZ1608-HE series of high-reliability chip beads for automotive use, compatible with high-durability solder in 150 ºC environments. This series marks the industry’s first* high-reliability chip bead specifically designed for automotive applications associated with engine control modules (ECM), anti-lock brake systems (ABS), electric power steering (EPS), electric and hybrid electric vehicles (EV/EHV), inverters and LED headlights.

TDK Corporation today announced the development and mass production of the MMZ1608-HE series of high-reliability chip beads for automotive use, compatible with high-durability solder in 150 ºC environments. This series marks the industry’s first* high-reliability chip bead specifically designed for automotive applications associated with engine control modules (ECM), anti-lock brake systems (ABS), electric power steering (EPS), electric and hybrid electric vehicles (EV/EHV), inverters and LED headlights..jpg) TDK Corporation (TSE:6762) today announced the development of its KCZ1210AH series of miniaturized common-mode filters for automotive applications. The series is extremely compact, measuring 1.25 (L) x 1.0 (W) x 0.5 mm (H), which contributes to a smaller footprint on substrate and provides a noise control function for different transmission signal lines for automobiles.

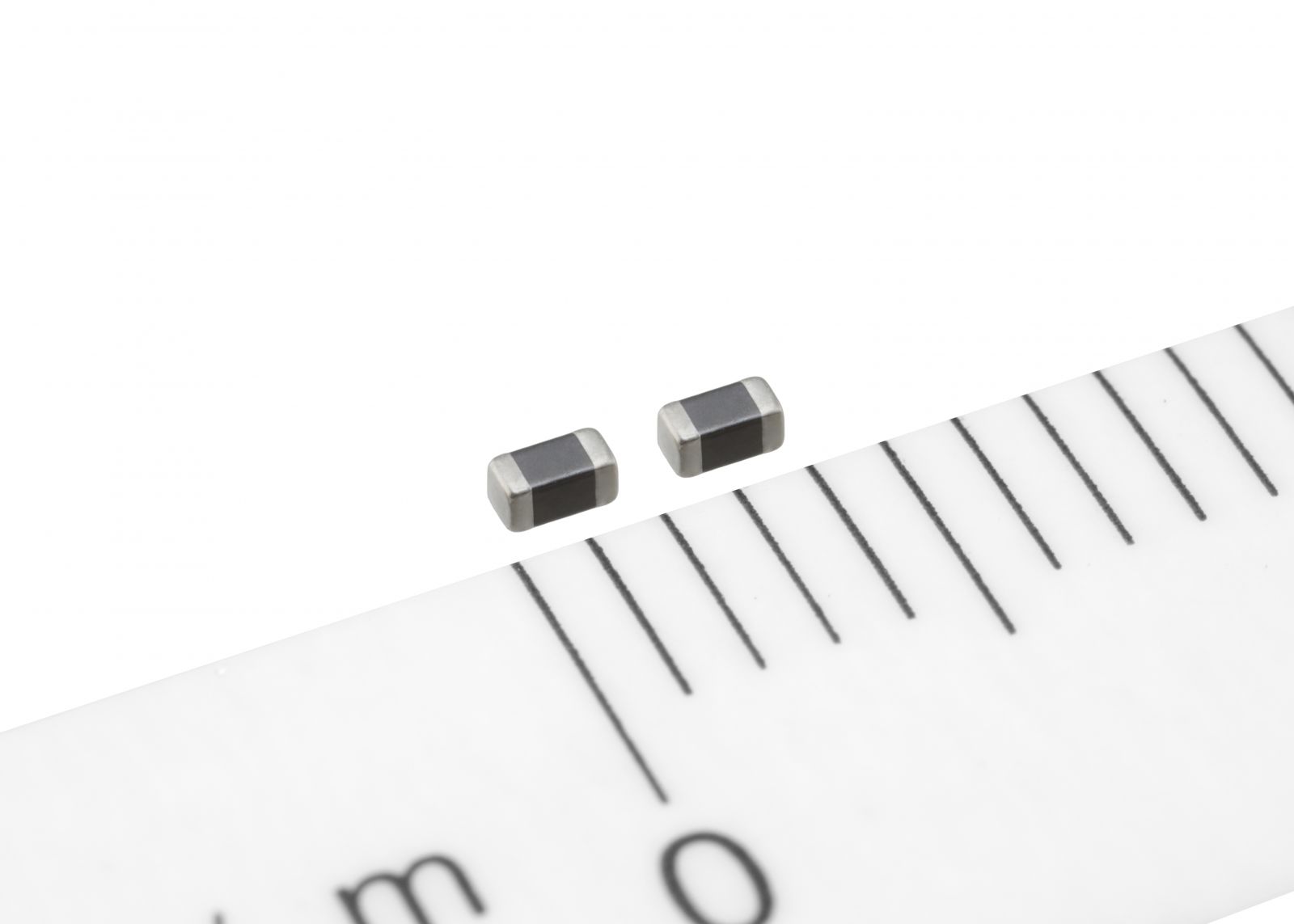

TDK Corporation (TSE:6762) today announced the development of its KCZ1210AH series of miniaturized common-mode filters for automotive applications. The series is extremely compact, measuring 1.25 (L) x 1.0 (W) x 0.5 mm (H), which contributes to a smaller footprint on substrate and provides a noise control function for different transmission signal lines for automobiles. TDK Corporation has developed the TCM0403M Series of miniaturized thin-film common-mode filters for mobile devices. The 0403 case size (0.45 x 0.3 x 0.23 mm) is 58 % smaller and 56 % lighter than previous products. With its high common-mode attenuation characteristic, these products reduce intruding noise and improve wireless signal reception sensitivity. The common mode attenuation at 2.4 GHz is 21 dB, and 28 dB at 5.0 GHz, with a maximum permissible current of 50 mA. Mass production started in August 2021.

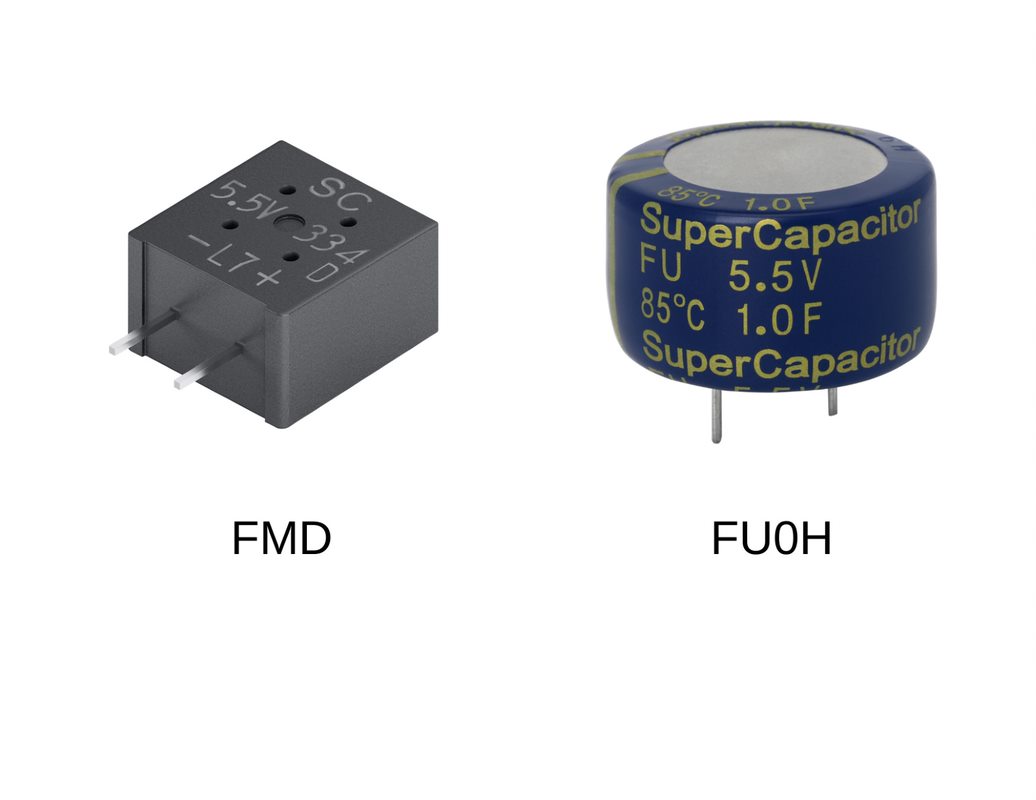

TDK Corporation has developed the TCM0403M Series of miniaturized thin-film common-mode filters for mobile devices. The 0403 case size (0.45 x 0.3 x 0.23 mm) is 58 % smaller and 56 % lighter than previous products. With its high common-mode attenuation characteristic, these products reduce intruding noise and improve wireless signal reception sensitivity. The common mode attenuation at 2.4 GHz is 21 dB, and 28 dB at 5.0 GHz, with a maximum permissible current of 50 mA. Mass production started in August 2021. KEMET, part of the YAGEO Group and leading global electronic components supplier, announces its new high-performance supercapacitors for automotive electronics, the FMD and FU0H series. These series deliver 1,000 hours at 85°C/85% RH-rated voltage and operational temperature ranging from -40°C to 85°C. The FMD series offers the highest lifetime with up to 4,000 hours. These supercapacitors are qualified to an automotive testing protocol. These capacitors are manufactured in an ISO TS 16949 certified plant and are subjected to PPAP/PSW and change control. They are ideal for automotive applications needing a main power system backup during a power loss, such as ADAS, autonomous vehicles, and central gateway ECUs. Supercapacitors are ideal for maintaining the main power system’s real-time clock or volatile memory when it is removed, such as during a power failure or when the main power system’s battery has been removed for replacement. Additionally, these supercapacitors offer power backup in equipment ranging from IoT devices, smart meters, medical devices, and industrial computing.

KEMET, part of the YAGEO Group and leading global electronic components supplier, announces its new high-performance supercapacitors for automotive electronics, the FMD and FU0H series. These series deliver 1,000 hours at 85°C/85% RH-rated voltage and operational temperature ranging from -40°C to 85°C. The FMD series offers the highest lifetime with up to 4,000 hours. These supercapacitors are qualified to an automotive testing protocol. These capacitors are manufactured in an ISO TS 16949 certified plant and are subjected to PPAP/PSW and change control. They are ideal for automotive applications needing a main power system backup during a power loss, such as ADAS, autonomous vehicles, and central gateway ECUs. Supercapacitors are ideal for maintaining the main power system’s real-time clock or volatile memory when it is removed, such as during a power failure or when the main power system’s battery has been removed for replacement. Additionally, these supercapacitors offer power backup in equipment ranging from IoT devices, smart meters, medical devices, and industrial computing. A recent Design Example Report (

A recent Design Example Report (.jpg) Typical eBike and power tool adapters come in bulky packages, with much of their volume devoted to thick, heavy metal heatsinks that siphon away wasted energy when they are charging.

Typical eBike and power tool adapters come in bulky packages, with much of their volume devoted to thick, heavy metal heatsinks that siphon away wasted energy when they are charging.  Utility meters need to work without interruption and often under adverse conditions. From full load to light load, through line surges, or even when being tampered with, meters require rugged and efficient power supplies to deliver power without fail. A new design example report (

Utility meters need to work without interruption and often under adverse conditions. From full load to light load, through line surges, or even when being tampered with, meters require rugged and efficient power supplies to deliver power without fail. A new design example report ( TDK Corporation (TSE: 6762) has developed a series of thin-film metal power inductors for automotive power circuits. The new TFM201210ALMA inductors feature a mounting area downsized approximately 22 % from TDK’s conventional product, TFM201610ALMA (2.0 mm (L) x 1.6 mm (W) x 1.0 mm (H)). Mass production will begin in August 2021.

TDK Corporation (TSE: 6762) has developed a series of thin-film metal power inductors for automotive power circuits. The new TFM201210ALMA inductors feature a mounting area downsized approximately 22 % from TDK’s conventional product, TFM201610ALMA (2.0 mm (L) x 1.6 mm (W) x 1.0 mm (H)). Mass production will begin in August 2021. PI’s newest AEC-Q100 qualified Qspeed diode has the lowest reverse recovery charge (Qrr) of any 600 V silicon diode. Expanding our portfolio of automotive-qualified diodes, the

PI’s newest AEC-Q100 qualified Qspeed diode has the lowest reverse recovery charge (Qrr) of any 600 V silicon diode. Expanding our portfolio of automotive-qualified diodes, the  Explore the low-cost MSP430FR243x family of FRAM-based microcontrollers

Explore the low-cost MSP430FR243x family of FRAM-based microcontrollers MSP430F2xx family: Get more from power from your MCU with integrated analog

MSP430F2xx family: Get more from power from your MCU with integrated analog MSP430FR247x family: Delivering integrated analog at extended temps

MSP430FR247x family: Delivering integrated analog at extended temps Capacitive sensing MSP430™ MCUs: Easiest to use capacitive touch solutions

Capacitive sensing MSP430™ MCUs: Easiest to use capacitive touch solutions  Simplify gas and liquid measurement with ultrasonic sensing MCUs

Simplify gas and liquid measurement with ultrasonic sensing MCUs Easy to use development kit for sensing solutions

Easy to use development kit for sensing solutions  Typical discrete AC zero-cross detection circuits require many components and consume as much as half of the standby power budget. Power Integrations’ new LinkSwitch-TNZ IC family solves this problem by combining offline power conversion, lossless zero-cross detection and optional X-capacitor discharge functions in a compact SO-8C package. With integrated lossless AC zero-cross detection, LinkSwitch-TNZ ICs provide best-in-class light-load efficiencies.

Typical discrete AC zero-cross detection circuits require many components and consume as much as half of the standby power budget. Power Integrations’ new LinkSwitch-TNZ IC family solves this problem by combining offline power conversion, lossless zero-cross detection and optional X-capacitor discharge functions in a compact SO-8C package. With integrated lossless AC zero-cross detection, LinkSwitch-TNZ ICs provide best-in-class light-load efficiencies. TDK Corporation (TSE:6762) has extended its range of coupled inductors to include the new EPCOS series B82472D6*. The nine series types cover an inductance range of 2 x 2.2 µH to 2 x 47 µH and are designed for maximum rated currents of 1.1 A to 4.3 A. The RoHS-compliant chokes are certified in line with AEC-Q200 and feature high saturation currents of up to 7.95 A. The magnetically shielded inductors have dimensions of just 7.3 x 7.3 x 4.8 mm and are designed for a wide temperature range of between -55 °C and +150 °C. Depending on the type, the chokes offer very high coupling factors of the two windings from 97 to 99 percent.

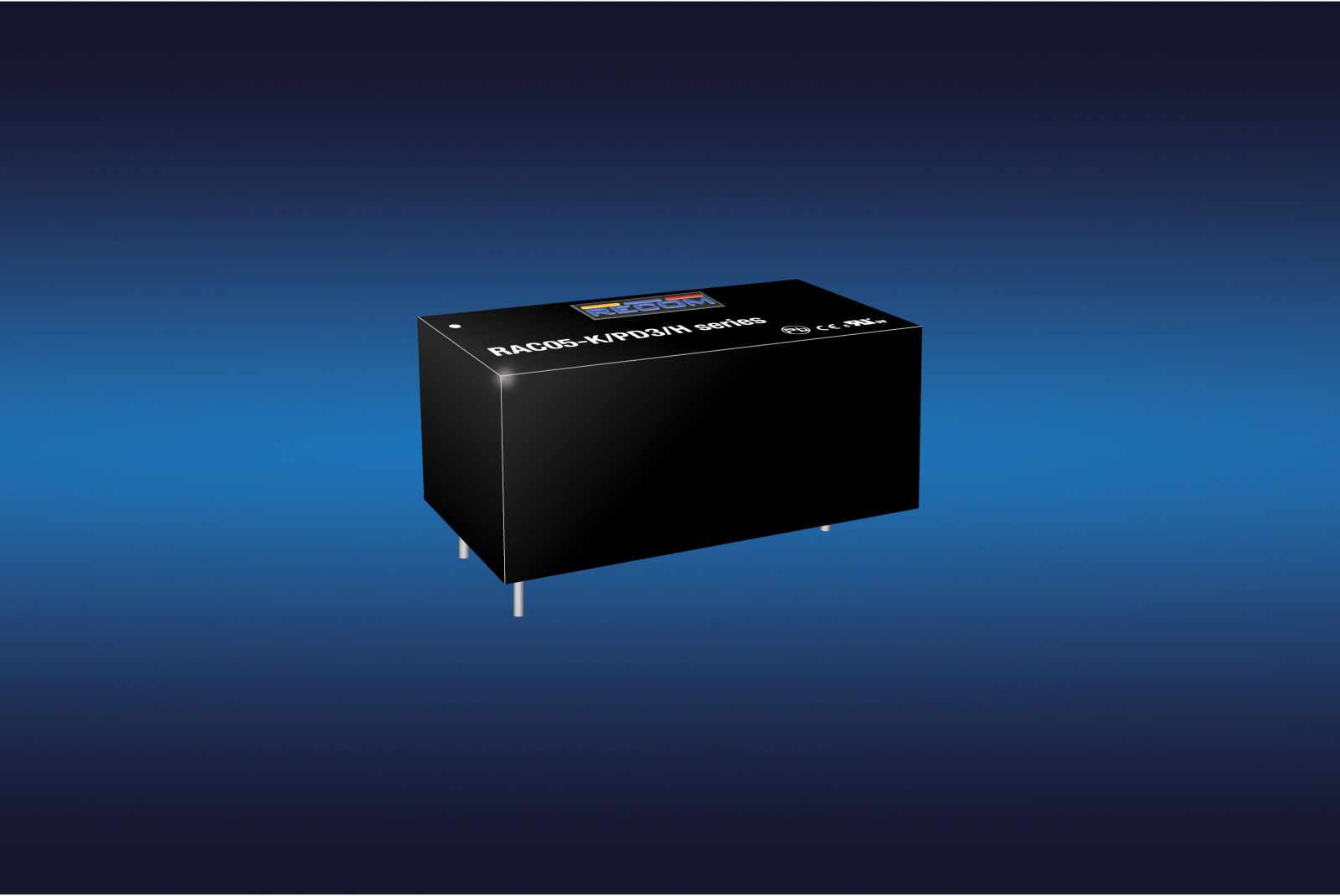

TDK Corporation (TSE:6762) has extended its range of coupled inductors to include the new EPCOS series B82472D6*. The nine series types cover an inductance range of 2 x 2.2 µH to 2 x 47 µH and are designed for maximum rated currents of 1.1 A to 4.3 A. The RoHS-compliant chokes are certified in line with AEC-Q200 and feature high saturation currents of up to 7.95 A. The magnetically shielded inductors have dimensions of just 7.3 x 7.3 x 4.8 mm and are designed for a wide temperature range of between -55 °C and +150 °C. Depending on the type, the chokes offer very high coupling factors of the two windings from 97 to 99 percent. The RAC05-K/PD3/H from RECOM is a board-mounted 5W Class II AC/DC converter series, intended for ‘fixed installations’ where higher levels of transients according to over-voltage category III are experienced, along with increased environmental pollution levels.

The RAC05-K/PD3/H from RECOM is a board-mounted 5W Class II AC/DC converter series, intended for ‘fixed installations’ where higher levels of transients according to over-voltage category III are experienced, along with increased environmental pollution levels. TDK Corporation developed new HPL505032F1 power inductors for use in automotive circuits. The inductors enable level 5 ADAS applications for cameras by offering high-current and low-inductance for power circuits in central processing units and graphic processing units, such as advanced driver-assistance systems (ADAS).

TDK Corporation developed new HPL505032F1 power inductors for use in automotive circuits. The inductors enable level 5 ADAS applications for cameras by offering high-current and low-inductance for power circuits in central processing units and graphic processing units, such as advanced driver-assistance systems (ADAS). Green energy and electric transportation systems have pushed explosive growth in inverter markets. Many of these applications present harsh operating environments for power electronics circuitry. Often, these applications demand a high percentage of uptime, increasing the need for highly reliable components. In response,

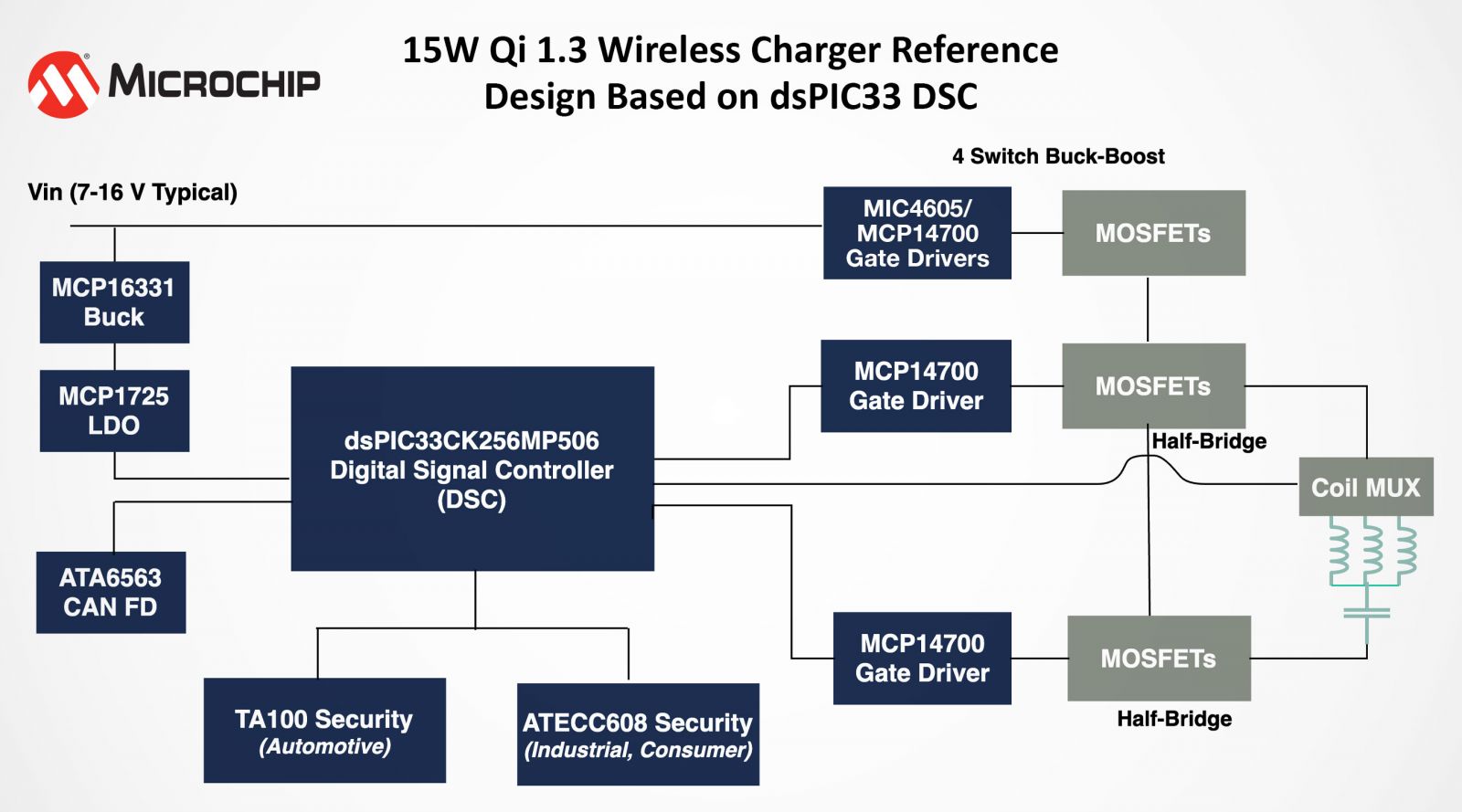

Green energy and electric transportation systems have pushed explosive growth in inverter markets. Many of these applications present harsh operating environments for power electronics circuitry. Often, these applications demand a high percentage of uptime, increasing the need for highly reliable components. In response,  The Wireless Power Consortium (WPC) has recently released the Qi 1.3 specification that requires authentication for improved safety when transmitting up to 15W of power between a transmitter and a receiver.

The Wireless Power Consortium (WPC) has recently released the Qi 1.3 specification that requires authentication for improved safety when transmitting up to 15W of power between a transmitter and a receiver..png) TDK Corporation presents the EPCOS aluminum electrolytic capacitors B43706* and B43726* series with screw terminals. The new components are designed for rated voltages between 400 V DC and 500 V DC and cover a capacitance range of 820 µF to 15,000 µF.

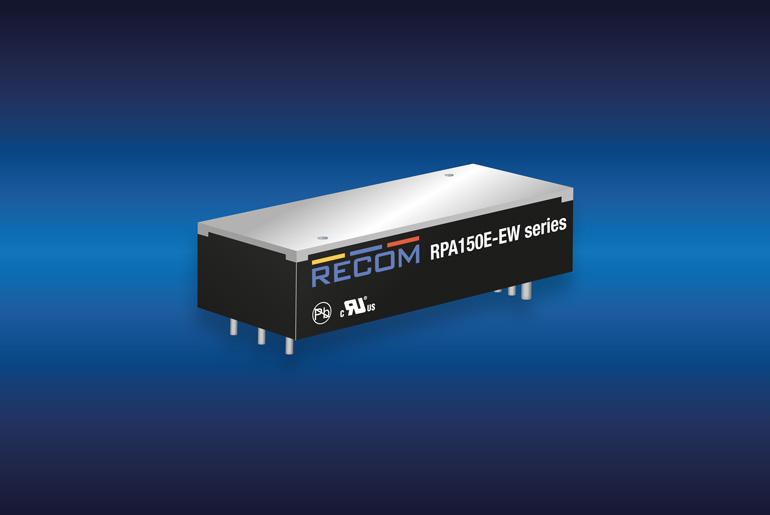

TDK Corporation presents the EPCOS aluminum electrolytic capacitors B43706* and B43726* series with screw terminals. The new components are designed for rated voltages between 400 V DC and 500 V DC and cover a capacitance range of 820 µF to 15,000 µF. RECOM has launched an eighth-brick DC/DC converter series with 9-60VDC input and optional 12, 24 or 48V outputs rated at 150W. The RPA150E series has an industry standard pin-out with outputs trimmable over a wide +/-20% range to include 28V for avionic systems and 57V for PoE applications. The 6:1 input range covers nominal 12, 24, and 48V system rails with sufficient margin to include 48V battery charging voltage and 12V battery cranking voltage dips.

RECOM has launched an eighth-brick DC/DC converter series with 9-60VDC input and optional 12, 24 or 48V outputs rated at 150W. The RPA150E series has an industry standard pin-out with outputs trimmable over a wide +/-20% range to include 28V for avionic systems and 57V for PoE applications. The 6:1 input range covers nominal 12, 24, and 48V system rails with sufficient margin to include 48V battery charging voltage and 12V battery cranking voltage dips.

The Power Sources Manufacturers Association (PSMA) announces the 2019 edition of the

The Power Sources Manufacturers Association (PSMA) announces the 2019 edition of the  The Power Sources Manufacturers Association (PSMA) Packaging Committee announces the publication of its latest report titled, “

The Power Sources Manufacturers Association (PSMA) Packaging Committee announces the publication of its latest report titled, “