|

ogniPower, LLC is a Research and Development company spun off from Lawson Labs, Inc. in 2009. Its purpose is to explore the opportunity opened by Predictive Energy Balancing (PEB) controls for switched mode power converters. PEB controls are based on a simple transformation of conventional control methods. By calculating energy, instead of using voltage, current or time as a proxy, PEB allows the gain of the control loop to be constant. That eliminates the need for delicate compensation or computation-intensive stabilization techniques. Because PEB controls closely follow the underlying physics, no tuning is required to accommodate different input and output voltages, or varying loads. Unprecedented stability and flexibility results.

ogniPower, LLC is a Research and Development company spun off from Lawson Labs, Inc. in 2009. Its purpose is to explore the opportunity opened by Predictive Energy Balancing (PEB) controls for switched mode power converters. PEB controls are based on a simple transformation of conventional control methods. By calculating energy, instead of using voltage, current or time as a proxy, PEB allows the gain of the control loop to be constant. That eliminates the need for delicate compensation or computation-intensive stabilization techniques. Because PEB controls closely follow the underlying physics, no tuning is required to accommodate different input and output voltages, or varying loads. Unprecedented stability and flexibility results.

PEB provides immediate benefits for switched mode power. The most dramatic difference is in transient response. PEB can provide true single-cycle response, even when presented with large, sudden load changes. Undershoot and overshoot can be limited to a single cycle. Operating frequencies can be increased (or decreased), without affecting stability. Other benefits follow from the improved tractability. Fewer, smaller clamps or snubbers are needed. Lower voltage parts can be used in the absence of voltage spikes. Because efficiency improves, heat sinks and fans are smaller, and reliability goes up as the operating temperature goes down. PEB provides immediate benefits for switched mode power. The most dramatic difference is in transient response. PEB can provide true single-cycle response, even when presented with large, sudden load changes. Undershoot and overshoot can be limited to a single cycle. Operating frequencies can be increased (or decreased), without affecting stability. Other benefits follow from the improved tractability. Fewer, smaller clamps or snubbers are needed. Lower voltage parts can be used in the absence of voltage spikes. Because efficiency improves, heat sinks and fans are smaller, and reliability goes up as the operating temperature goes down.

The generalized nature of these controls suits them for granular power applications, where the power converter is closely wedded to the circuit being powered. The absence of compensation components saves I/O pins and extends the operating range. Because the behavior matches the theory, digital control is painless. PEB's intrinsic stability means that no intermediate digital control steps are needed to transition between various operating conditions. The discontinuities found between different operating modes in conventional digital power systems are entirely absent with PEB. Because a PEB control loop can run faster than conventional loops, it is well suited for newer, faster switches like GaN and SiC and GaS. Particularly with these faster switches, extra care must be taken with switch drivers and switch geometry to control stay inductance. CogniPower has worked out proprietary techniques for achieving clean switching at high frequencies and edge rates.

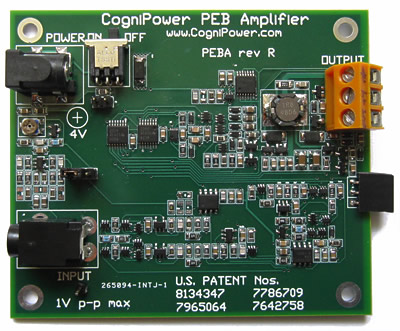

CogniPower has built demonstration systems ranging from 50mW to 1kW. Performance exceeds expectations. One bidirectional forward converter demonstration board is so agile, you can substitute an audio signal for the DC reference voltage and the power converter will produce high fidelity audio at the output. The results when using conventional controls would sound quite different. The point here is that these power converters can maintain near-ideal regulation under circumstances that will drive ordinary power converters out of their safe operating area. The agility and flexibility of PEB make several new topologies practical. These may seem like science fiction to those accustomed to delicately balanced, marginally stable power converters, but they are firmly grounded in reality. One new topology power converter is developed to the point that it is scheduled to go into production soon. That one is called the Compound Converter. It is a Power Factor Correcting AC/DC converter with a well-regulated output. The key difference is that most of the power moves through only a single stage of power conversion. An entire transformer can be eliminated, shrinking size and cost while improving the Power Factor and the efficiency. A Compound Converter can improve any "brick" power converter, including those used for laptops and flat panel displays. Other new topologies target sine-wave output motor controllers, multi-port power converters, bidirectional converters and switched-mode power amplifiers capable of envelope tracking, to name a few. A related line of investigation led to an ultra-low standby power wall-mount adapter. A simple, patent-pending design provides unheard of efficiency at low loads (95% efficiency at 25% load), improved regulation with a smaller filter capacitor, smaller size, and lower cost. CogniPower holds nine issued patents and has more than that many again in process. Our technology is finding its way into a variety of markets. We continue to expand and refine the core technology and to build demonstration systems showing the expanded capabilities of PEB controls. The next step will be to find the right partners to apply this new technology to more and broader markets.

Visit www.cognipower.com for more information.

Provided by Thomas Lawson,

President, CogniPower, LLC

DEMANDING APPLICATIONS DEMAND TDI POWER

DI Power is a leading global manufacturer of highly reliable Power System Solutions for the Industrial, Commercial Aerospace, Vehicle, Medical, and Test & Measurement markets. Its broad range of high technology power conversion products includes DC and AC Power Systems, Power Supplies, Rectifiers, Converters, electronic loads and accessory equipment. Established in 1960, TDI is headquartered in New Jersey, USA, has over 600 employees and three facilities located throughout the world. DI Power is a leading global manufacturer of highly reliable Power System Solutions for the Industrial, Commercial Aerospace, Vehicle, Medical, and Test & Measurement markets. Its broad range of high technology power conversion products includes DC and AC Power Systems, Power Supplies, Rectifiers, Converters, electronic loads and accessory equipment. Established in 1960, TDI is headquartered in New Jersey, USA, has over 600 employees and three facilities located throughout the world.

TDI Powers’ products can be found in applications such as powering aircraft entertainment screens, aircraft laptop power plugs, semiconductor manufacturing equipment, industrial process control equipment, electric vehicles, mobile medical carts, communications equipment, and military solutions. TDI’s power solutions include:

- Liquid Cooled: sealed converters ideal for clean room applications, as well as suitable for environmentally uncontrolled industrial environments.

- Inverters: a series of modular DC-AC inverters used in applications such as telecommunications, data centers, alternative energy, industrial and military.

- Power Systems: highly configurable AC-DC converters for applications, such as industrial gas generation, communication systems, rapid battery charging, cathodic protection and many more.

- ESPM: a complete series of Environmentally Sealed Power Modules that can withstand outdoor harsh environments. This mechanical and electrical design is extremely rugged, built with convection cooling that environmentally seals the equipment and protects the components.

- MediPower: a fully integrated power system and battery utilized in the medical industry for medical carts, medicine dispensers, telemedicine and in patient triage.

- Dynaload: a high power density DC electronic load, used for a wide variety of power source test requirements, ranging from DC power supplies to fuel cells to batteries, and more. It is available in single or multi-channel air cooled, single channel water cooled or parallel multiple Dynaloads into a rack system.

- Aircraft AC Power Sources: AC power supplies used for in-seat personal electronic devices

- Aircraft DC Supplies: Airborne DC power supplies used in audio and video applications for inflight entertainment

- Defender Series: Liquid cooled DC power system for Cathodic Protection to control the corrosion of metal surfaces in applications such as pipelines, storage tanks, oil platforms, ships and boat hulls

- Phase3 Series: LiquaBlade is a 3 phase hot swap liquid cooled DC power system, which provides 16.5kW of power in a 1U shelf. High voltage semiconductor components enabled direct 380-480VAC input without step down transformer.

- Programmable Current Source: Power converters with highly precise source programmability.

- Programmable Voltage Source: Power converters with highly precise voltage source programmability.

- Transient Boost Converters: Supporting transient power loads with a DC-DC boost converter in diesel/ gas generator applications.

- Rack Systems: Highly configurable, scalable redundant power systems ideal when paralleling large quantities of converters for large scale systems.

For more information about TDI Power, go to www.tdipower.com.

Provided by Jan Kapushinsky,

Sr. Marketing Comm. Manager, TDI Power

Editor's Note: We would like to feature your company in a future issue of the Update. Please contact the Association Office for information about how to submit an article for consideration.

|